Ice cream makers with a built-in timer offer precise batch control, ensuring consistent freezing times and perfect texture without needing constant attention. Manual monitoring allows users to adjust the process based on personal preference, providing flexibility but requiring more involvement. Choosing between the two depends on whether convenience or hands-on customization is a priority for crafting ideal homemade ice cream.

Table of Comparison

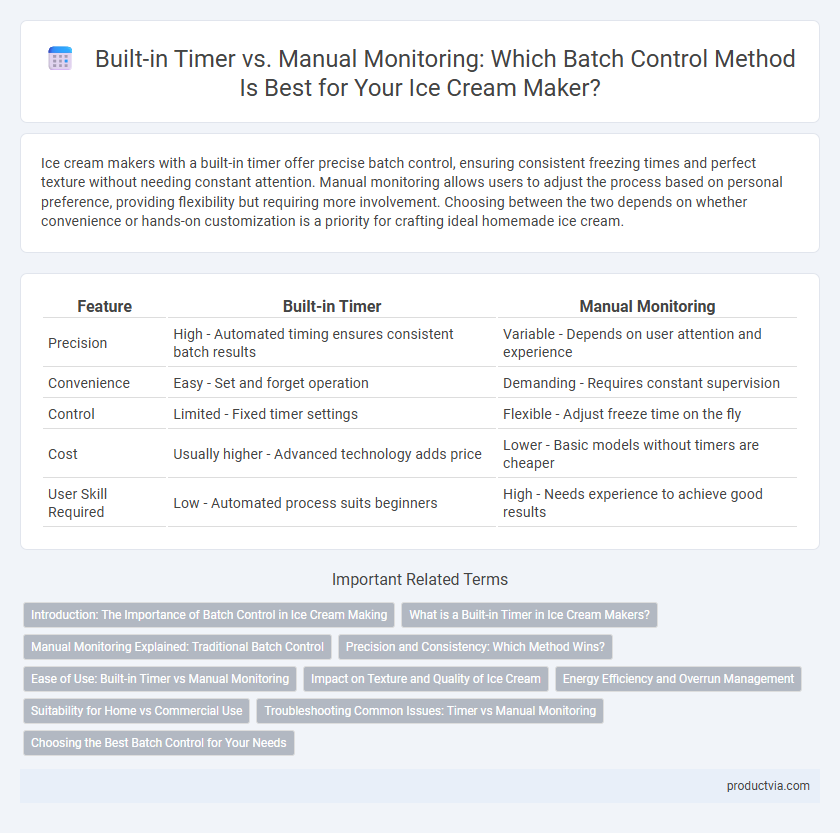

| Feature | Built-in Timer | Manual Monitoring |

|---|---|---|

| Precision | High - Automated timing ensures consistent batch results | Variable - Depends on user attention and experience |

| Convenience | Easy - Set and forget operation | Demanding - Requires constant supervision |

| Control | Limited - Fixed timer settings | Flexible - Adjust freeze time on the fly |

| Cost | Usually higher - Advanced technology adds price | Lower - Basic models without timers are cheaper |

| User Skill Required | Low - Automated process suits beginners | High - Needs experience to achieve good results |

Introduction: The Importance of Batch Control in Ice Cream Making

Precise batch control in ice cream making ensures consistent texture and optimal freezing, which directly impacts flavor and quality. Built-in timers automate the freezing process, reducing human error and allowing for consistent batch durations. Manual monitoring offers flexibility to adjust mixing time based on real-time texture observations, catering to unique recipes and personal preferences.

What is a Built-in Timer in Ice Cream Makers?

A built-in timer in ice cream makers allows precise control over the freezing and churning process by automatically stopping the machine after a preset duration, ensuring consistent texture and preventing overfreezing. This feature eliminates the need for constant manual monitoring, making it convenient for users to multitask or prepare multiple batches sequentially. Models with built-in timers often include customizable settings to accommodate various recipes and desired firmness levels, enhancing batch control efficiency.

Manual Monitoring Explained: Traditional Batch Control

Manual monitoring in traditional ice cream makers involves attentively observing the batch's texture and consistency throughout the freezing process to achieve the desired creaminess. Operators rely on tactile and visual cues to decide when to stop mixing, ensuring optimal air incorporation and smoothness without over-churning. This hands-on approach demands experience and active involvement, offering precise control over batch quality without preset timers.

Precision and Consistency: Which Method Wins?

A built-in timer in ice cream makers ensures precise control over churning duration, leading to consistent texture and optimal freezing without the risk of over- or under-processing. Manual monitoring, while offering flexibility, often results in variable batch quality due to human error and timing inconsistencies. For achieving uniform results, the built-in timer method outperforms manual monitoring by delivering reliable, repeatable batches with minimal supervision.

Ease of Use: Built-in Timer vs Manual Monitoring

A built-in timer in an ice cream maker enhances ease of use by allowing users to set precise churning durations, eliminating the need for constant supervision. Manual monitoring requires active attention to timing and consistency, which can be less convenient and may lead to inconsistent results. Timers streamline batch control, ensuring perfectly churned ice cream with minimal user effort.

Impact on Texture and Quality of Ice Cream

A built-in timer in ice cream makers ensures consistent batch control, resulting in a smoother and creamier texture by preventing over-churning or under-processing. Manual monitoring allows for flexibility to adjust the churning time based on the mixture's consistency but risks user error, potentially leading to icy or grainy ice cream. Precise timing significantly impacts the quality of ice cream by maintaining optimal air incorporation and preventing ice crystal formation.

Energy Efficiency and Overrun Management

A built-in timer in ice cream makers enhances energy efficiency by precisely controlling batch duration, preventing unnecessary power consumption and minimizing spoilage risk. Manual monitoring requires constant attention, increasing the chance of overrun mismanagement, which impacts texture and consistency negatively. Optimizing batch control through timer integration ensures accurate overrun levels, leading to superior ice cream quality and reduced operational costs.

Suitability for Home vs Commercial Use

A built-in timer in ice cream makers offers precise batch control, ideal for home users seeking convenience and consistent results without constant supervision. Manual monitoring, preferred in commercial settings, allows for flexibility and adjustment based on texture and consistency, catering to varied batch sizes and ingredient complexities. Home users benefit from automation, while commercial operations prioritize hands-on control for quality customization.

Troubleshooting Common Issues: Timer vs Manual Monitoring

Built-in timers in ice cream makers simplify batch control by automatically stopping the process, reducing the risk of over-churning and ensuring consistent texture. Manual monitoring allows for personalized adjustments, helping to address issues like inconsistent freezing or under- or over-churning by visually assessing the mixture's progress. Troubleshooting common problems involves balancing the convenience of timers for uniform results with hands-on observation to fine-tune texture and firmness based on real-time conditions.

Choosing the Best Batch Control for Your Needs

A built-in timer in an ice cream maker offers precise control over mixing and freezing durations, ensuring consistent texture and reducing the risk of over-processing. Manual monitoring provides flexibility to adjust based on real-time observation, ideal for customized recipes or varying ingredient conditions. Selecting the best batch control depends on your preference for convenience and consistency versus hands-on customization and attention.

Built-in Timer vs Manual Monitoring for Batch Control Infographic

productvia.com

productvia.com