Direct drive motors in ice cream makers offer superior durability due to their simplified design, which minimizes wear and tear by eliminating belts and pulleys. Belt drive motors can experience decreased performance over time as belts stretch or break, requiring regular maintenance or replacement. Choosing a direct drive motor ensures longer-lasting operation and consistent performance for your ice cream making needs.

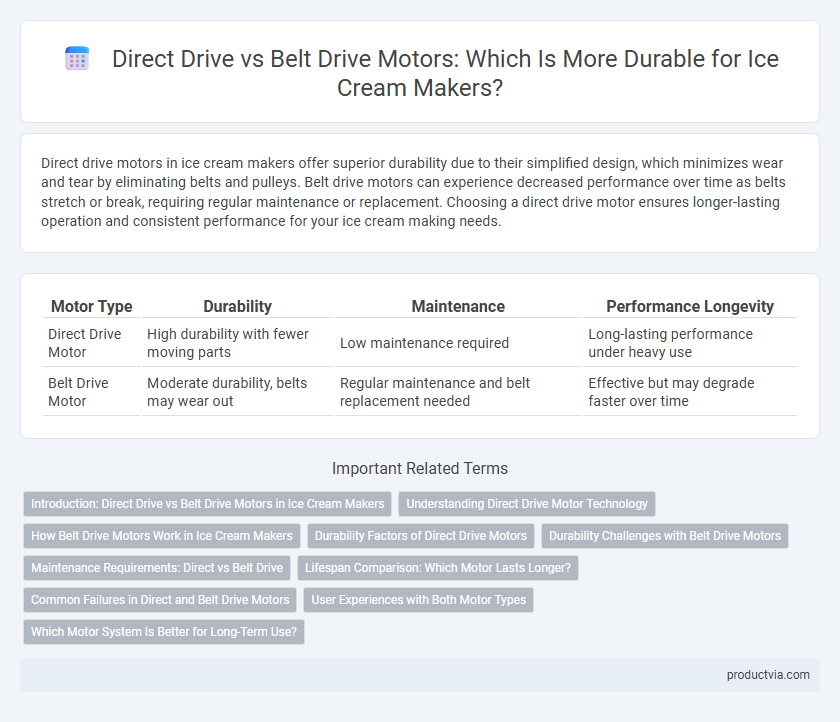

Table of Comparison

| Motor Type | Durability | Maintenance | Performance Longevity |

|---|---|---|---|

| Direct Drive Motor | High durability with fewer moving parts | Low maintenance required | Long-lasting performance under heavy use |

| Belt Drive Motor | Moderate durability, belts may wear out | Regular maintenance and belt replacement needed | Effective but may degrade faster over time |

Introduction: Direct Drive vs Belt Drive Motors in Ice Cream Makers

Direct drive motors in ice cream makers offer superior durability by eliminating belts, reducing wear and maintenance needs. Belt drive motors rely on rubber belts that can stretch or break over time, leading to potential operational issues. Choosing a direct drive motor enhances long-term reliability and consistent performance in home ice cream machines.

Understanding Direct Drive Motor Technology

Direct drive motor technology in ice cream makers enhances durability by eliminating belts that can wear out or break, resulting in fewer mechanical failures. This motor type connects the motor directly to the mixing paddle, providing consistent torque and reducing noise during operation. Understanding the direct drive design helps users prioritize long-term reliability and low-maintenance performance in their ice cream machines.

How Belt Drive Motors Work in Ice Cream Makers

Belt drive motors in ice cream makers operate by using a belt to connect the motor to the mixing paddle, enabling smooth and consistent churning. This mechanism reduces strain on the motor by distributing the load, which can enhance the overall durability of the appliance. However, belt wear and tension may require periodic maintenance to ensure optimal performance and prolong the ice cream maker's lifespan.

Durability Factors of Direct Drive Motors

Direct drive motors in ice cream makers offer superior durability due to fewer moving parts and a direct connection between the motor and the mixing mechanism, reducing wear and tear. These motors typically run cooler and have enhanced torque control, resulting in prolonged motor life and consistent performance. The lack of belts eliminates the risk of belt slippage or breakage, making direct drive systems more reliable and maintenance-free over time.

Durability Challenges with Belt Drive Motors

Direct drive motors in ice cream makers offer superior durability by eliminating belts that wear out or slip over time, reducing maintenance needs. Belt drive motors face durability challenges such as belt stretching, cracking, or breaking, which can lead to motor misalignment and operational failure. The increased mechanical stress and frequent belt replacements make belt drive systems less reliable for long-term use in ice cream makers.

Maintenance Requirements: Direct vs Belt Drive

Direct drive motors in ice cream makers offer superior durability due to fewer moving parts and a more compact design, resulting in minimal maintenance requirements. Belt drive motors require regular belt inspections, adjustments, and replacements to maintain optimal performance and avoid breakdowns. Choosing a direct drive motor reduces maintenance frequency and extends the appliance's lifespan, making it a practical option for consistent use.

Lifespan Comparison: Which Motor Lasts Longer?

Direct drive motors in ice cream makers typically offer greater durability due to their simpler design, resulting in fewer components prone to wear over time. Belt drive motors contain additional moving parts like belts and pulleys that can degrade or break, shortening the appliance's overall lifespan. Studies indicate direct drive motors often last 20-30% longer than belt drive motors under regular use conditions.

Common Failures in Direct and Belt Drive Motors

Direct drive motors in ice cream makers typically exhibit greater durability due to fewer moving parts, reducing common failures such as belt wear and slippage found in belt drive motors. Belt drive motors often encounter issues like belt breakage, tension loss, and misalignment, which can lead to inconsistent performance and frequent maintenance. Manufacturers favor direct drive systems for their robust reliability and longer lifespan under continuous use conditions.

User Experiences with Both Motor Types

Direct drive motors in ice cream makers offer enhanced durability due to fewer moving parts, resulting in less wear and longer lifespan as reported by users who value consistent performance over time. Belt drive motors, while typically quieter and easier to repair, tend to experience more frequent wear and require periodic belt replacements, leading to mixed user experiences regarding long-term reliability. Consumer reviews highlight that direct drive models are preferred for heavy or frequent use, whereas belt drive machines are often chosen for occasional home use coupled with easier maintenance.

Which Motor System Is Better for Long-Term Use?

Direct drive motors in ice cream makers offer superior durability due to fewer moving parts and reduced mechanical wear, ensuring consistent long-term performance. Belt drive motors, while often quieter and less expensive, tend to experience more frequent wear and require periodic maintenance or belt replacements. For long-term use, direct drive motor systems are generally more reliable and cost-effective over time.

Direct Drive Motor vs Belt Drive Motor for Durability Infographic

productvia.com

productvia.com