A single batch ice cream maker pet produces a fixed amount of ice cream each cycle, ideal for small servings and home use. Continuous batch machines offer higher output by allowing ongoing production, suitable for larger quantities and commercial settings. Choosing between the two depends on the volume needed and the frequency of use.

Table of Comparison

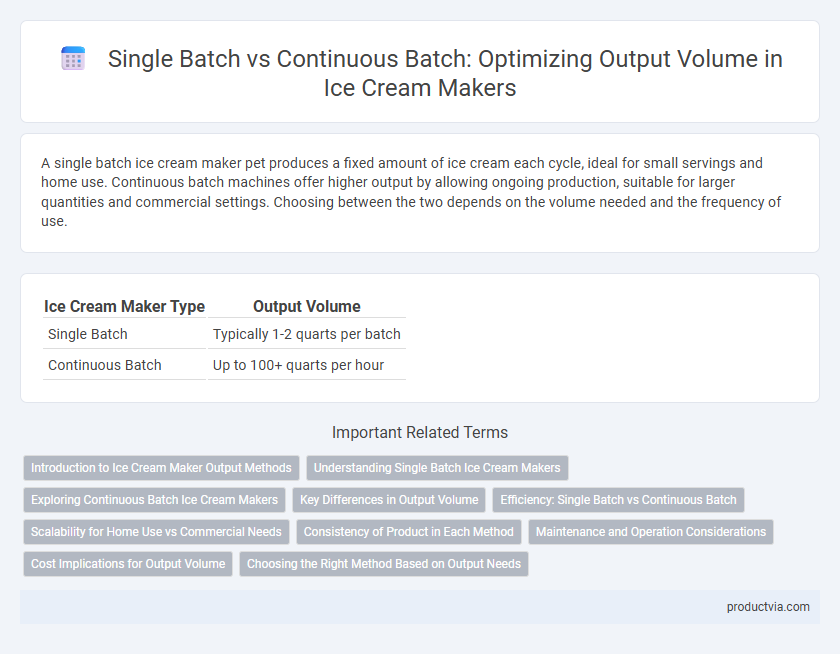

| Ice Cream Maker Type | Output Volume |

|---|---|

| Single Batch | Typically 1-2 quarts per batch |

| Continuous Batch | Up to 100+ quarts per hour |

Introduction to Ice Cream Maker Output Methods

Single batch ice cream makers produce limited quantities per cycle, ideal for home use with output volumes typically ranging from 1 to 2 quarts. Continuous batch machines support larger scale production, maintaining steady output volumes suitable for commercial environments, often exceeding 5 quarts per hour. Understanding the output methods helps in selecting an ice cream maker that matches production demands and operational efficiency.

Understanding Single Batch Ice Cream Makers

Single batch ice cream makers produce a limited volume of ice cream per cycle, ideal for home use or small-scale production where quality and customization are prioritized over quantity. These machines typically churn 1 to 2 quarts per batch, allowing precise control over texture and ingredient integration. Understanding single batch models is essential for users seeking fresh, artisanal ice cream without the high output demands of commercial continuous batch machines.

Exploring Continuous Batch Ice Cream Makers

Continuous batch ice cream makers offer significant advantages in output volume by allowing ongoing production without interruption, ideal for commercial use and high-demand environments. Unlike single batch machines, continuous batch models utilize a consistent freezing and mixing process that can produce large quantities of ice cream efficiently. This results in faster turnaround times and the ability to meet higher consumer volume with uniform texture and quality.

Key Differences in Output Volume

Single batch ice cream makers produce limited quantities per cycle, typically ranging from 1 to 2 quarts, making them ideal for small-scale or home use. Continuous batch machines can output significantly higher volumes, often exceeding 10 quarts per hour, catering to commercial demands. The key difference lies in the throughput capacity, with continuous batch models delivering consistent, large-scale production while single batch units focus on smaller, precise servings.

Efficiency: Single Batch vs Continuous Batch

Single batch ice cream makers offer precise control over small quantities, making them ideal for artisanal production with consistent quality. Continuous batch models excel in high-volume output by continuously freezing and churning, maximizing efficiency for commercial operations. Efficiency in continuous batch systems reduces downtime and energy consumption per unit, significantly increasing overall productivity compared to single batch machines.

Scalability for Home Use vs Commercial Needs

Single batch ice cream makers offer limited output volumes ideal for home use, producing small quantities per cycle with consistent quality. Continuous batch machines enable scalable production, efficiently handling larger volumes required for commercial settings without sacrificing texture or flavor. Choosing between single and continuous batch models depends on desired output volume, with single batch suiting personal consumption and continuous batch meeting extensive commercial demand.

Consistency of Product in Each Method

Single batch ice cream makers produce smaller quantities with precise control over texture and flavor, ensuring consistent quality in each batch. Continuous batch machines yield higher volumes, but variations can occur due to fluctuations in mixing and freezing processes over extended runs. Consistency tends to be superior in single batch methods due to careful monitoring, while continuous batches prioritize volume output but may sacrifice uniformity.

Maintenance and Operation Considerations

Single batch ice cream makers require frequent cleaning after each use, increasing maintenance time but allowing for smaller output volumes and greater flavor flexibility. Continuous batch machines are designed for high-volume production with streamlined operations, featuring automated cleaning systems that reduce downtime but demand higher initial maintenance expertise. Choosing between the two depends on balancing output volume needs with operational efficiency and maintenance resources.

Cost Implications for Output Volume

Single batch ice cream makers produce limited quantities per cycle, resulting in higher per-unit costs due to frequent cleaning and labor demands. Continuous batch machines support larger output volumes by running uninterrupted, which lowers production costs through economies of scale and reduced downtime. Investing in continuous batch equipment is cost-effective for commercial operations requiring high-volume ice cream production.

Choosing the Right Method Based on Output Needs

Selecting between single batch and continuous batch ice cream makers depends on desired output volume and production efficiency. Single batch machines are ideal for small-scale or artisanal production, offering precise flavor control but limited output per cycle. Continuous batch machines support high-volume output with consistent quality, suitable for commercial operations requiring uninterrupted production.

Single Batch vs Continuous Batch for Output Volume Infographic

productvia.com

productvia.com