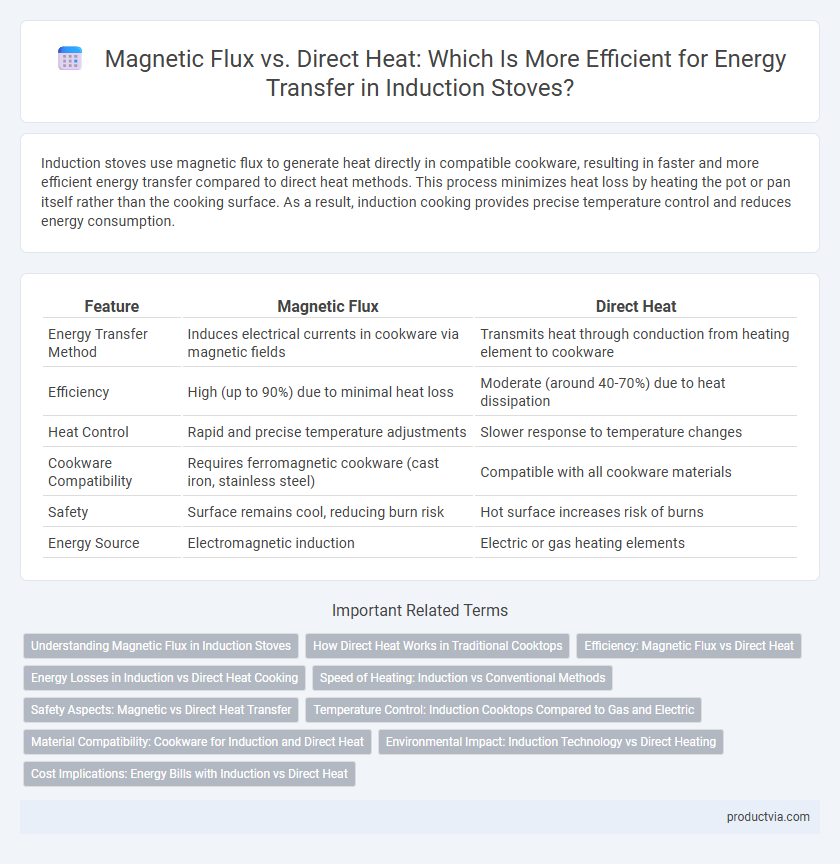

Induction stoves use magnetic flux to generate heat directly in compatible cookware, resulting in faster and more efficient energy transfer compared to direct heat methods. This process minimizes heat loss by heating the pot or pan itself rather than the cooking surface. As a result, induction cooking provides precise temperature control and reduces energy consumption.

Table of Comparison

| Feature | Magnetic Flux | Direct Heat |

|---|---|---|

| Energy Transfer Method | Induces electrical currents in cookware via magnetic fields | Transmits heat through conduction from heating element to cookware |

| Efficiency | High (up to 90%) due to minimal heat loss | Moderate (around 40-70%) due to heat dissipation |

| Heat Control | Rapid and precise temperature adjustments | Slower response to temperature changes |

| Cookware Compatibility | Requires ferromagnetic cookware (cast iron, stainless steel) | Compatible with all cookware materials |

| Safety | Surface remains cool, reducing burn risk | Hot surface increases risk of burns |

| Energy Source | Electromagnetic induction | Electric or gas heating elements |

Understanding Magnetic Flux in Induction Stoves

Magnetic flux in induction stoves generates an alternating electromagnetic field that directly induces electric currents in ferromagnetic cookware, producing heat through resistance without the need for direct contact. This process contrasts with direct heat transfer found in conventional stoves, where heat moves from the burner to the pot via conduction. Understanding magnetic flux efficiency explains why induction stoves provide faster, more precise heating with less energy loss compared to traditional methods.

How Direct Heat Works in Traditional Cooktops

Traditional cooktops transfer energy through direct heat by heating the burner element or gas flame, which then transfers thermal energy directly to the cookware's surface. This process relies on conduction and convection, resulting in slower and less efficient energy transfer compared to magnetic flux induction. Direct heat causes temperature gradients within the cookware, often leading to uneven cooking and greater heat loss to the surrounding environment.

Efficiency: Magnetic Flux vs Direct Heat

Magnetic flux in induction stoves generates heat directly within the cookware through electromagnetic induction, minimizing energy loss and achieving efficiency rates of up to 90%. Direct heat methods, such as gas or traditional electric stoves, transfer heat indirectly via a burner, resulting in significant energy loss with efficiency typically around 40-55%. This superior energy transfer efficiency in induction stoves translates into faster cooking times and reduced energy consumption.

Energy Losses in Induction vs Direct Heat Cooking

Induction stoves transfer energy through magnetic flux by generating an electromagnetic field that directly heats the cookware, resulting in energy losses of approximately 5-10%. Direct heat cooking, such as gas or electric coil stoves, relies on conduction and radiation, where energy losses can exceed 40% due to heat dissipation into the surrounding air. This higher efficiency in induction cooking minimizes wasted energy and enhances overall energy transfer effectiveness compared to traditional direct heat methods.

Speed of Heating: Induction vs Conventional Methods

Induction stoves use magnetic flux to generate heat directly within the cookware, enabling rapid temperature increases and faster cooking times compared to conventional direct heat methods. This targeted energy transfer minimizes heat loss and delivers efficient, immediate heating. Conventional stoves rely on flame or electric coils to transfer heat externally, resulting in slower temperature ramp-up and greater energy dissipation.

Safety Aspects: Magnetic vs Direct Heat Transfer

Induction stoves use magnetic flux to generate heat directly within the cookware, eliminating open flames and reducing the risk of burns and fire hazards compared to direct heat transfer methods like gas or electric coils. This magnetic induction process confines heat to the pot or pan, leaving the cooking surface cooler and safer to touch, minimizing accidental burns. Safety features inherent to magnetic flux-based induction cooking include automatic shut-off when no pot is detected and reduced carbon monoxide emissions, making it a safer energy transfer method.

Temperature Control: Induction Cooktops Compared to Gas and Electric

Induction cooktops utilize magnetic flux to generate heat directly within the cookware, resulting in rapid and precise temperature control unmatched by gas or electric stoves. Unlike direct heat from gas flames or electric coils, which heats cookware indirectly and often unevenly, induction stoves adjust power instantly by modulating the electromagnetic field, providing accurate temperature settings from simmering to boiling. This efficient energy transfer minimizes heat loss and ensures consistent cooking results, making induction technology superior for temperature-sensitive culinary tasks.

Material Compatibility: Cookware for Induction and Direct Heat

Magnetic flux in induction stoves requires cookware with ferromagnetic materials like cast iron or stainless steel to efficiently transfer energy through electromagnetic fields, ensuring rapid and uniform heating. Direct heat methods are compatible with a wider range of materials, including aluminum, copper, and glass, but often result in uneven heat distribution and slower energy transfer. Selecting induction-compatible cookware optimizes energy efficiency and cooking performance by maximizing magnetic flux interaction.

Environmental Impact: Induction Technology vs Direct Heating

Induction stoves use magnetic flux to generate heat directly within the cookware, resulting in higher energy efficiency and reduced energy waste compared to direct heat methods. Direct heating transfers heat through conduction and convection, leading to greater heat loss and increased greenhouse gas emissions when powered by fossil fuels. The environmentally friendly nature of induction technology lowers carbon footprints, supporting sustainable cooking practices and reducing overall environmental impact.

Cost Implications: Energy Bills with Induction vs Direct Heat

Magnetic flux in induction stoves generates heat directly within the cookware through electromagnetic fields, resulting in higher energy efficiency and lower energy bills compared to direct heat methods such as gas or electric coil stoves. Direct heat systems transfer thermal energy indirectly, causing significant heat loss and increased energy consumption, which elevates overall operating costs. The efficient energy transfer of induction technology reduces monthly electricity expenses, offering long-term financial savings despite higher initial appliance costs.

Magnetic flux vs Direct heat for energy transfer Infographic

productvia.com

productvia.com