Pulp ejector juicers streamline cleaning by automatically expelling pulp into a separate container, reducing manual handling and residue buildup. Non-ejector juicers require frequent stopping to remove pulp manually, which can prolong the cleaning process. Choosing a pulp ejector juicer enhances convenience and efficiency, especially for users prioritizing quick, hassle-free cleanup.

Table of Comparison

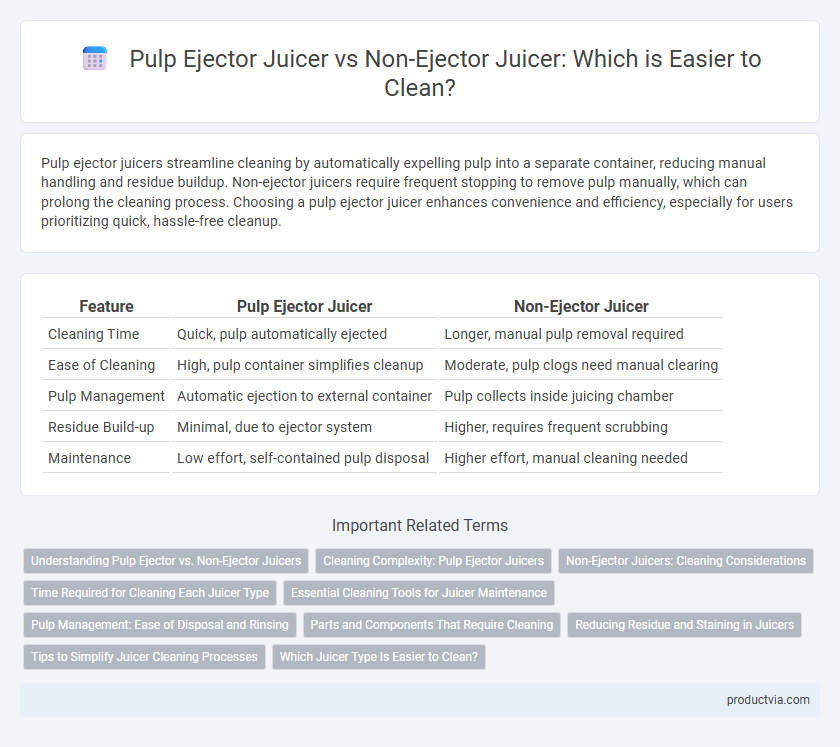

| Feature | Pulp Ejector Juicer | Non-Ejector Juicer |

|---|---|---|

| Cleaning Time | Quick, pulp automatically ejected | Longer, manual pulp removal required |

| Ease of Cleaning | High, pulp container simplifies cleanup | Moderate, pulp clogs need manual clearing |

| Pulp Management | Automatic ejection to external container | Pulp collects inside juicing chamber |

| Residue Build-up | Minimal, due to ejector system | Higher, requires frequent scrubbing |

| Maintenance | Low effort, self-contained pulp disposal | Higher effort, manual cleaning needed |

Understanding Pulp Ejector vs. Non-Ejector Juicers

Pulp ejector juicers expel pulp automatically into a separate container, significantly simplifying the cleaning process by reducing residue inside the juicer. Non-ejector juicers require manual removal of pulp from the juice container, often necessitating frequent disassembly and thorough washing to prevent clogging. Choosing a pulp ejector juicer enhances efficiency in cleanup, especially for users who juice frequently and prefer minimal maintenance effort.

Cleaning Complexity: Pulp Ejector Juicers

Pulp ejector juicers simplify cleaning by automatically expelling pulp into a designated container, reducing residue buildup inside the machine. This feature minimizes the need for disassembling multiple parts after each use, making maintenance faster and more user-friendly. However, the pulp container still requires regular emptying and rinsing to ensure optimal hygiene.

Non-Ejector Juicers: Cleaning Considerations

Non-ejector juicers require disassembling the entire unit for thorough cleaning since the pulp remains inside the machine, which can prolong the cleaning process and increase maintenance efforts. Residual pulp buildup inside the juicer components may lead to clogging and odors if not cleaned immediately after use. Proper soaking and scrubbing of the filter basket, auger, and pulp chamber are essential to maintain hygiene and ensure optimal juicing performance.

Time Required for Cleaning Each Juicer Type

Pulp ejector juicers significantly reduce cleaning time by automatically expelling pulp into an external container, minimizing residue buildup inside the machine. Non-ejector juicers require manual removal of pulp from the internal chamber, increasing cleaning time and effort. Users seeking quick cleanup benefit from the efficient pulp management system of ejector juicers, making post-juicing maintenance faster.

Essential Cleaning Tools for Juicer Maintenance

Pulp ejector juicers simplify cleaning by automatically expelling pulp into a separate container, reducing the need to dismantle internal parts frequently. Non-ejector juicers require more thorough disassembly and manual removal of pulp, demanding comprehensive cleaning brushes and sponges to reach all crevices. Essential cleaning tools include durable nylon brushes with varying bristle stiffness, silicone scrapers, and fine mesh strainers for efficient removal of pulp residues and maintaining optimal juicer performance.

Pulp Management: Ease of Disposal and Rinsing

Pulp ejector juicers simplify pulp management by automatically expelling pulp into a separate container, allowing for easy disposal and minimal residue buildup inside the juicer. Non-ejector juicers require manual removal of pulp, often leading to longer cleaning times and more thorough rinsing to avoid clogging. Efficient pulp ejection reduces cleaning frequency and enhances juicer longevity by preventing pulp accumulation in hard-to-reach areas.

Parts and Components That Require Cleaning

Pulp ejector juicers feature a dedicated pulp ejection system that requires regular cleaning of the pulp receptacle, ejection chute, and associated seals to prevent buildup and ensure smooth operation. Non-ejector juicers have a more integrated pulp container, demanding thorough cleaning of the juicing chamber, mesh filter, and pulp container to avoid clogging and maintain juice quality. Both types require detailed attention to removable parts such as blades, strainers, and collection cups to ensure hygienic use and prolong appliance lifespan.

Reducing Residue and Staining in Juicers

Pulp ejector juicers significantly reduce residue buildup by automatically expelling pulp, minimizing clogging and staining within the juicing chamber. In contrast, non-ejector juicers retain pulp inside, increasing the frequency of residue accumulation and requiring more intensive cleaning to prevent discoloration. Choosing a pulp ejector juicer enhances ease of maintenance and prolongs the appliance's cleanliness by effectively reducing leftover pulp and juice stains.

Tips to Simplify Juicer Cleaning Processes

Pulp ejector juicers streamline cleaning by automatically expelling pulp into a separate container, significantly reducing residue buildup inside the device. Non-ejector juicers require frequent disassembly and manual removal of pulp, demanding more time and effort for thorough cleaning. To simplify maintenance, rinse parts immediately after use and employ specialized brushes designed for juicer components to prevent clogging and ensure optimal hygiene.

Which Juicer Type Is Easier to Clean?

Pulp ejector juicers simplify cleaning by automatically expelling pulp into a separate container, reducing residue buildup inside the juice chamber. Non-ejector juicers require manual removal and disposal of pulp, which can increase cleaning time and effort. Users seeking convenience and quicker cleanup typically prefer pulp ejector models for daily juicing.

Pulp ejector juicer vs Non-ejector juicer for cleaning Infographic

productvia.com

productvia.com