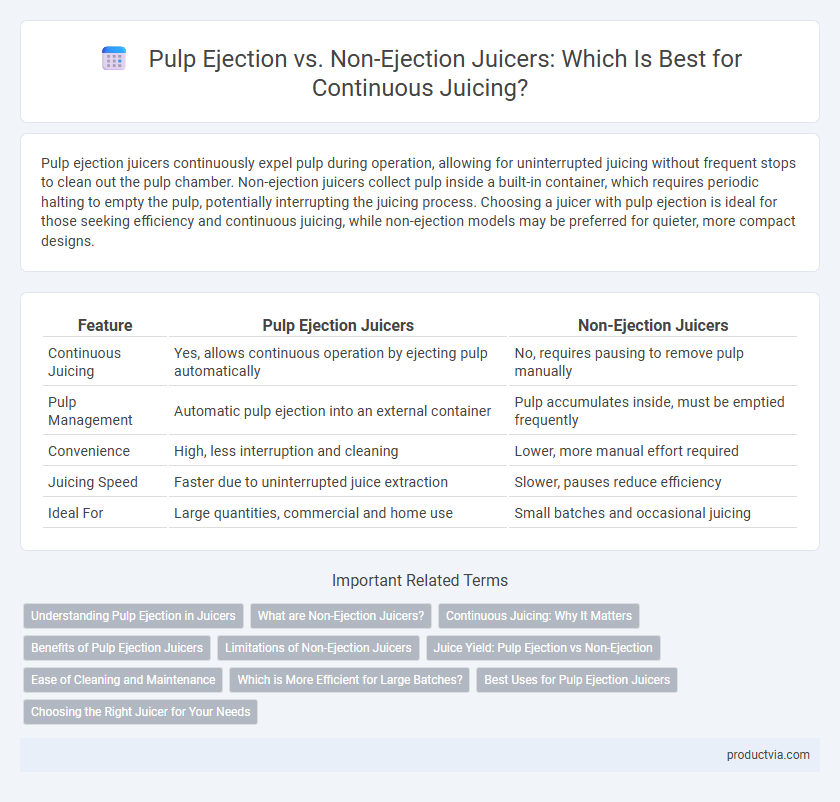

Pulp ejection juicers continuously expel pulp during operation, allowing for uninterrupted juicing without frequent stops to clean out the pulp chamber. Non-ejection juicers collect pulp inside a built-in container, which requires periodic halting to empty the pulp, potentially interrupting the juicing process. Choosing a juicer with pulp ejection is ideal for those seeking efficiency and continuous juicing, while non-ejection models may be preferred for quieter, more compact designs.

Table of Comparison

| Feature | Pulp Ejection Juicers | Non-Ejection Juicers |

|---|---|---|

| Continuous Juicing | Yes, allows continuous operation by ejecting pulp automatically | No, requires pausing to remove pulp manually |

| Pulp Management | Automatic pulp ejection into an external container | Pulp accumulates inside, must be emptied frequently |

| Convenience | High, less interruption and cleaning | Lower, more manual effort required |

| Juicing Speed | Faster due to uninterrupted juice extraction | Slower, pauses reduce efficiency |

| Ideal For | Large quantities, commercial and home use | Small batches and occasional juicing |

Understanding Pulp Ejection in Juicers

Pulp ejection in juicers allows continuous juicing by automatically expelling pulp into a separate container, preventing clogging and maintaining consistent juice flow. Non-ejection juicers collect pulp internally, which requires frequent stops to manually remove it, reducing juicing efficiency. Understanding the differences in pulp management helps choose the right juicer for uninterrupted, high-volume juice extraction.

What are Non-Ejection Juicers?

Non-ejection juicers are designed to collect pulp inside the juicer rather than expelling it continuously during juicing. This feature allows for quieter operation and less mess, making them ideal for continuous juicing sessions where users can empty the pulp container as needed. Non-ejection models often provide better control over pulp consistency and reduce interruptions compared to ejection juicers.

Continuous Juicing: Why It Matters

Continuous juicing efficiency depends heavily on pulp management; pulp ejection juicers expel pulp during operation, preventing clogging and maintaining consistent juice flow for extended use. Non-ejection juicers collect pulp internally, requiring frequent stops to empty the container, which disrupts juicing continuity. For users seeking uninterrupted performance, pulp ejection models optimize continuous juicing by enabling longer sessions without pause.

Benefits of Pulp Ejection Juicers

Pulp ejection juicers continuously expel pulp into a separate container, allowing for uninterrupted juicing sessions without frequent stops to clear the pulp chamber. This feature enhances efficiency and convenience, making pulp ejection models ideal for high-volume or commercial use. Additionally, they produce smoother juice with less residue, improving overall juice quality and taste.

Limitations of Non-Ejection Juicers

Non-ejection juicers accumulate pulp inside the chamber, requiring frequent stops to manually remove the pulp, which disrupts continuous juicing and lowers efficiency. This buildup can lead to clogging, overheating, and reduced juice extraction performance over time. The interruption limits productivity and is less suitable for high-volume juicing tasks compared to pulp ejection models.

Juice Yield: Pulp Ejection vs Non-Ejection

Juicers with pulp ejection systems typically offer higher juice yield during continuous juicing by automatically expelling pulp, preventing clogging and maintaining consistent extraction efficiency. Non-ejection juicers accumulate pulp inside the chamber, which can reduce juice output over time as the pulp builds up and inhibits the juicing process. The continuous removal of pulp in ejection models enhances airflow and pressure, maximizing juice extraction and overall productivity.

Ease of Cleaning and Maintenance

Pulp ejection juicers offer continuous juicing by automatically expelling pulp into a separate container, significantly reducing interruptions for cleaning. Non-ejection juicers require frequent stopping to remove accumulated pulp, making the cleaning process more labor-intensive during extended use. Choosing pulp ejection models enhances ease of maintenance, ensuring smoother operation and less downtime.

Which is More Efficient for Large Batches?

Pulp ejection juicers continuously expel pulp during operation, preventing clogging and allowing for uninterrupted juicing of large batches, making them highly efficient for extended use. Non-ejection juicers accumulate pulp inside a container, requiring frequent stops to empty the pulp, which can slow down the juicing process for large quantities. For maximum efficiency in processing large batches, pulp ejection models reduce downtime and maintain consistent juice flow.

Best Uses for Pulp Ejection Juicers

Pulp ejection juicers are ideal for continuous juicing sessions, allowing users to extract juice without stopping to remove pulp frequently. Their design automatically ejects pulp into a separate container, making them perfect for high-volume juicing or preparing large batches of fresh juice efficiently. Best used for leafy greens, fruits, and vegetables that produce a significant amount of pulp, these juicers streamline the process and enhance convenience in commercial or heavy home use.

Choosing the Right Juicer for Your Needs

Pulp ejection juicers continuously expel pulp through a separate outlet, allowing for uninterrupted juicing ideal for high-volume use and easy cleanup. Non-ejection juicers collect pulp internally, requiring periodic stops to empty the container, which may slow down continuous juicing but often result in more compact, quieter machines. Selecting between pulp ejection and non-ejection models depends on frequency of use, desired juicing speed, and convenience preferences.

Pulp ejection vs Non-ejection for continuous juicing Infographic

productvia.com

productvia.com