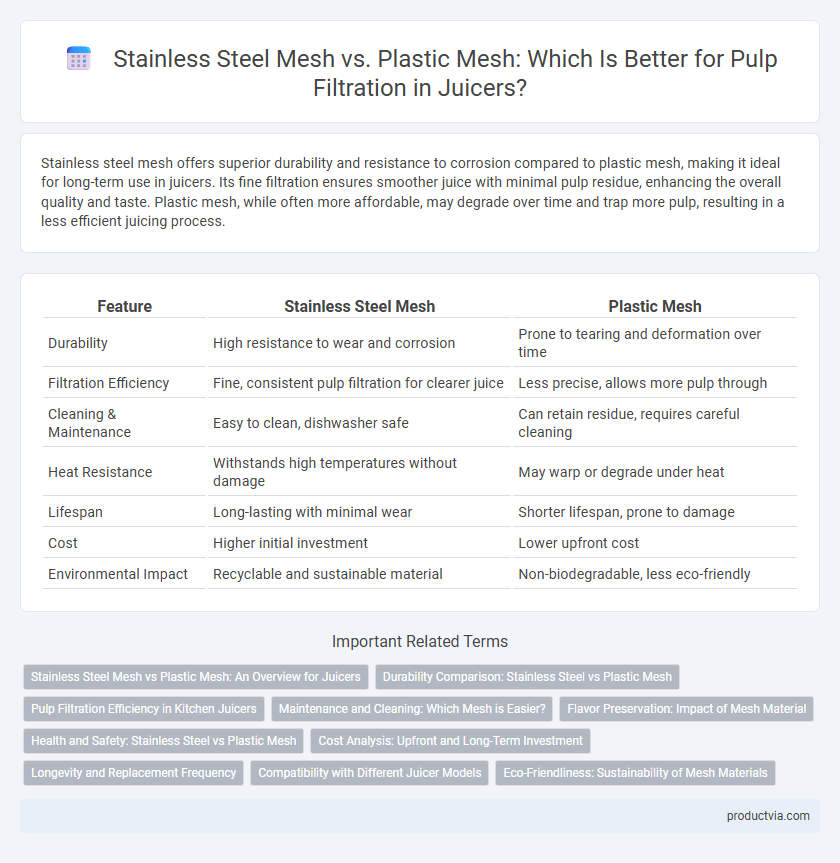

Stainless steel mesh offers superior durability and resistance to corrosion compared to plastic mesh, making it ideal for long-term use in juicers. Its fine filtration ensures smoother juice with minimal pulp residue, enhancing the overall quality and taste. Plastic mesh, while often more affordable, may degrade over time and trap more pulp, resulting in a less efficient juicing process.

Table of Comparison

| Feature | Stainless Steel Mesh | Plastic Mesh |

|---|---|---|

| Durability | High resistance to wear and corrosion | Prone to tearing and deformation over time |

| Filtration Efficiency | Fine, consistent pulp filtration for clearer juice | Less precise, allows more pulp through |

| Cleaning & Maintenance | Easy to clean, dishwasher safe | Can retain residue, requires careful cleaning |

| Heat Resistance | Withstands high temperatures without damage | May warp or degrade under heat |

| Lifespan | Long-lasting with minimal wear | Shorter lifespan, prone to damage |

| Cost | Higher initial investment | Lower upfront cost |

| Environmental Impact | Recyclable and sustainable material | Non-biodegradable, less eco-friendly |

Stainless Steel Mesh vs Plastic Mesh: An Overview for Juicers

Stainless steel mesh offers superior durability and resistance to wear compared to plastic mesh, making it ideal for long-term use in juicers. It provides finer filtration, capturing more pulp and resulting in smoother juice, while plastic mesh tends to degrade over time and may retain odors or stains. Choosing stainless steel mesh enhances hygiene and performance, ensuring efficient pulp filtration and easier cleaning for juicing enthusiasts.

Durability Comparison: Stainless Steel vs Plastic Mesh

Stainless steel mesh offers superior durability compared to plastic mesh for pulp filtration in juicers, resisting wear, corrosion, and high temperatures over extended use. Plastic mesh tends to degrade, crack, or deform under prolonged exposure to moisture and mechanical stress, reducing filtration efficiency over time. Investing in stainless steel mesh ensures longer-lasting performance and consistent pulp separation, making it a preferred choice for heavy-duty and frequent juicer use.

Pulp Filtration Efficiency in Kitchen Juicers

Stainless steel mesh offers superior pulp filtration efficiency in kitchen juicers due to its fine, durable construction that effectively separates juice from fibrous pulp without clogging. Plastic mesh often lacks the precision and longevity of stainless steel, resulting in less efficient pulp separation and a higher likelihood of residue buildup. Choosing stainless steel mesh enhances juice clarity and extends the juicer's operational lifespan.

Maintenance and Cleaning: Which Mesh is Easier?

Stainless steel mesh offers superior durability and resists staining, making it easier to clean with simple rinsing or brushing, even after extended use. Plastic mesh, while lighter, tends to retain pulp residues and stains more easily, requiring frequent soaking and vigorous scrubbing to maintain hygiene. Choosing stainless steel mesh significantly reduces maintenance time and effort, ensuring consistent pulp filtration performance over time.

Flavor Preservation: Impact of Mesh Material

Stainless steel mesh for pulp filtration in juicers preserves flavor by preventing oxidation and retaining the natural taste of fruits, offering durability and resistance to staining. Plastic mesh may absorb odors and flavors over time, leading to potential flavor contamination and less fresh juice output. Choosing stainless steel mesh enhances juice purity and maintains optimal flavor integrity during extraction.

Health and Safety: Stainless Steel vs Plastic Mesh

Stainless steel mesh offers superior health and safety benefits for pulp filtration in juicers due to its corrosion resistance and non-porous surface, which minimizes bacterial growth and ensures easier cleaning. Plastic mesh, while lightweight and cost-effective, may harbor bacteria in micro-scratches and degrade over time, potentially releasing harmful chemicals into the juice. Choosing stainless steel mesh enhances hygiene and durability, reducing health risks associated with plastic mesh use in juicer pulp filtration.

Cost Analysis: Upfront and Long-Term Investment

Stainless steel mesh pulp filters typically demand a higher upfront investment due to durable materials and manufacturing processes but offer superior longevity, reducing replacement frequency and maintenance costs over time. Plastic mesh options are generally more cost-effective initially, but their susceptibility to wear and tear leads to more frequent replacements, increasing long-term expenses. Analyzing total cost of ownership reveals stainless steel mesh as a more economical choice for heavy or prolonged juicer use owing to its durability and resistance to corrosion.

Longevity and Replacement Frequency

Stainless steel mesh in juicers offers superior longevity compared to plastic mesh due to its robust, corrosion-resistant properties, ensuring sustained performance without deformation. Plastic mesh filters tend to degrade faster, requiring more frequent replacements as they warp or crack under repeated use and exposure to acidic fruit juices. Investing in stainless steel mesh significantly reduces maintenance costs and downtime, enhancing juicer efficiency over time.

Compatibility with Different Juicer Models

Stainless steel mesh offers superior compatibility with a wide range of juicer models due to its durability and resistance to wear, making it ideal for heavy-duty and commercial juicers. Plastic mesh is typically limited to specific juicer brands and models, often used in budget-friendly or compact designs where metal parts could add unnecessary weight or cost. Choosing between stainless steel and plastic mesh depends heavily on the juicer's motor strength, design specifications, and intended usage frequency to ensure optimal pulp filtration performance.

Eco-Friendliness: Sustainability of Mesh Materials

Stainless steel mesh offers superior durability and recyclability compared to plastic mesh, making it a more sustainable choice for pulp filtration in juicers. It resists wear and corrosion, reducing the frequency of replacements and minimizing waste accumulation. Plastic mesh, often derived from petroleum-based materials, contributes to environmental pollution due to limited biodegradability and challenges in recycling processes.

Stainless Steel Mesh vs Plastic Mesh for Pulp Filtration Infographic

productvia.com

productvia.com