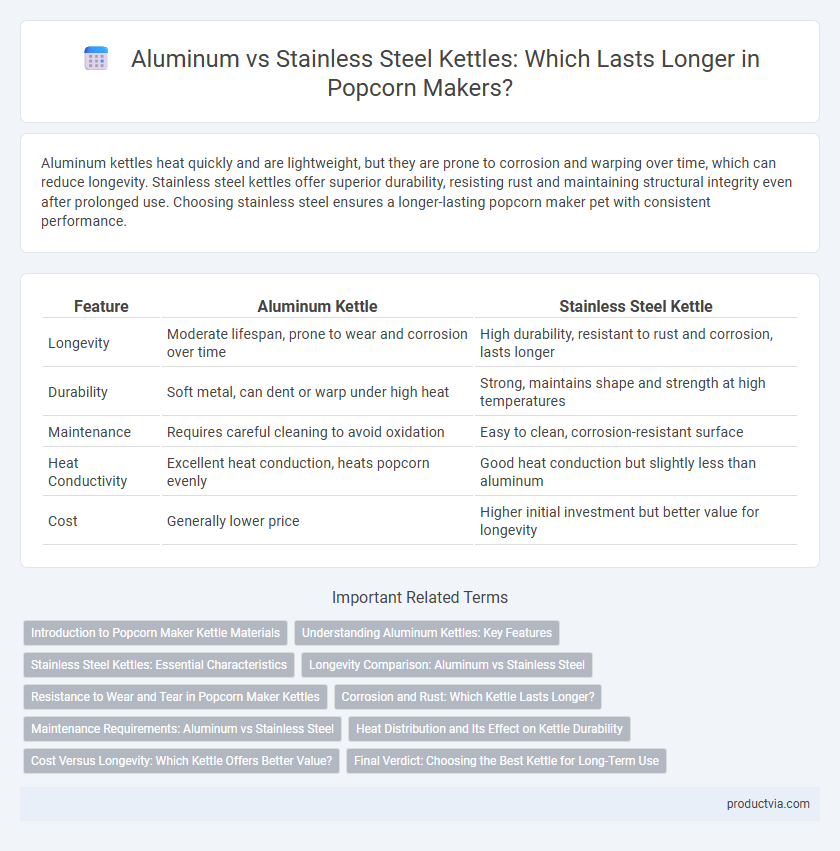

Aluminum kettles heat quickly and are lightweight, but they are prone to corrosion and warping over time, which can reduce longevity. Stainless steel kettles offer superior durability, resisting rust and maintaining structural integrity even after prolonged use. Choosing stainless steel ensures a longer-lasting popcorn maker pet with consistent performance.

Table of Comparison

| Feature | Aluminum Kettle | Stainless Steel Kettle |

|---|---|---|

| Longevity | Moderate lifespan, prone to wear and corrosion over time | High durability, resistant to rust and corrosion, lasts longer |

| Durability | Soft metal, can dent or warp under high heat | Strong, maintains shape and strength at high temperatures |

| Maintenance | Requires careful cleaning to avoid oxidation | Easy to clean, corrosion-resistant surface |

| Heat Conductivity | Excellent heat conduction, heats popcorn evenly | Good heat conduction but slightly less than aluminum |

| Cost | Generally lower price | Higher initial investment but better value for longevity |

Introduction to Popcorn Maker Kettle Materials

Stainless steel kettles offer superior resistance to rust and corrosion, ensuring longer durability compared to aluminum kettles in popcorn makers. Aluminum kettles heat quickly and evenly but may warp or degrade faster under high temperatures and frequent use. Selecting a popcorn maker with a stainless steel kettle enhances longevity and maintains consistent popping performance over time.

Understanding Aluminum Kettles: Key Features

Aluminum kettles offer excellent heat conductivity, enabling quick and even heating essential for popping popcorn efficiently. These kettles are lightweight and resist corrosion, though they may be prone to warping under high heat compared to stainless steel models. Understanding aluminum kettles' key features helps evaluate their durability, as they balance affordability with reasonable longevity in popcorn makers.

Stainless Steel Kettles: Essential Characteristics

Stainless steel kettles for popcorn makers are prized for their exceptional durability and resistance to corrosion, ensuring long-lasting performance even with frequent use. Their non-reactive surface prevents any metallic taste from transferring to the popcorn, maintaining flavor purity. The robust construction of stainless steel kettles also offers superior heat retention and distribution, contributing to consistently popped kernels and minimal burning.

Longevity Comparison: Aluminum vs Stainless Steel

Stainless steel kettles offer superior longevity compared to aluminum due to their resistance to rust, corrosion, and warping over time. Aluminum kettles, while lightweight and quick to heat, are prone to oxidation and may degrade faster with frequent use. For durable popcorn makers, stainless steel kettles ensure extended lifespan and consistent performance in high-heat environments.

Resistance to Wear and Tear in Popcorn Maker Kettles

Stainless steel kettles in popcorn makers offer superior resistance to wear and tear compared to aluminum, providing enhanced durability and a longer lifespan. The non-corrosive properties of stainless steel prevent rust and maintain structural integrity under high heat conditions, which is common during popcorn popping. Aluminum kettles, while lightweight, are more prone to dents and corrosion, reducing their longevity in commercial and heavy-use environments.

Corrosion and Rust: Which Kettle Lasts Longer?

Stainless steel kettles outperform aluminum kettles in corrosion resistance and rust prevention, making them more durable for long-term use in popcorn makers. Aluminum kettles may corrode over time when exposed to moisture and heat, leading to potential contamination and decreased lifespan. Choosing a stainless steel kettle ensures better longevity due to its strong resistance to rust and chemical degradation.

Maintenance Requirements: Aluminum vs Stainless Steel

Aluminum kettles require more frequent cleaning to prevent oxidation and discoloration, while stainless steel kettles resist rust and corrosion, significantly reducing maintenance efforts. Stainless steel's non-porous surface inhibits buildup and staining, enabling easier and less frequent cleaning compared to aluminum. Choosing stainless steel enhances longevity by minimizing the risk of material degradation through regular use and cleaning cycles.

Heat Distribution and Its Effect on Kettle Durability

Aluminum kettles offer excellent heat distribution due to their high thermal conductivity, promoting even cooking and reducing hot spots that can degrade popcorn quality. Stainless steel kettles, while having lower thermal conductivity, provide superior durability and corrosion resistance, extending the lifespan of the popcorn maker. Optimal heat management in aluminum kettles may improve popcorn texture but requires careful maintenance to prevent wear, whereas stainless steel kettles ensure long-term durability despite slower heat dispersion.

Cost Versus Longevity: Which Kettle Offers Better Value?

Aluminum kettles offer lower upfront costs but tend to wear out faster due to corrosion and warping, leading to more frequent replacements. Stainless steel kettles, while more expensive initially, provide superior durability and resistance to rust, ensuring longer service life and reducing long-term expenses. Evaluating cost versus longevity, stainless steel kettles deliver better value for frequent popcorn makers seeking a reliable and lasting appliance.

Final Verdict: Choosing the Best Kettle for Long-Term Use

Stainless steel kettles offer superior resistance to rust, corrosion, and wear, making them ideal for long-term popcorn making. Aluminum kettles, although lightweight and fast-heating, are prone to denting and oxidation, which can compromise durability over time. For longevity and maintaining consistent performance, stainless steel remains the preferred choice for popcorn makers.

Aluminum kettle vs stainless steel kettle for longevity Infographic

productvia.com

productvia.com