Butter melting well on a popcorn maker pet ensures even coating and enhances flavor absorption compared to a butter spritzer, which can result in uneven distribution and patches of soggy popcorn. The warm butter flows smoothly over each kernel, providing a consistent, rich taste that a spritzer's mist may fail to deliver. This method maximizes flavor while maintaining the ideal popcorn texture.

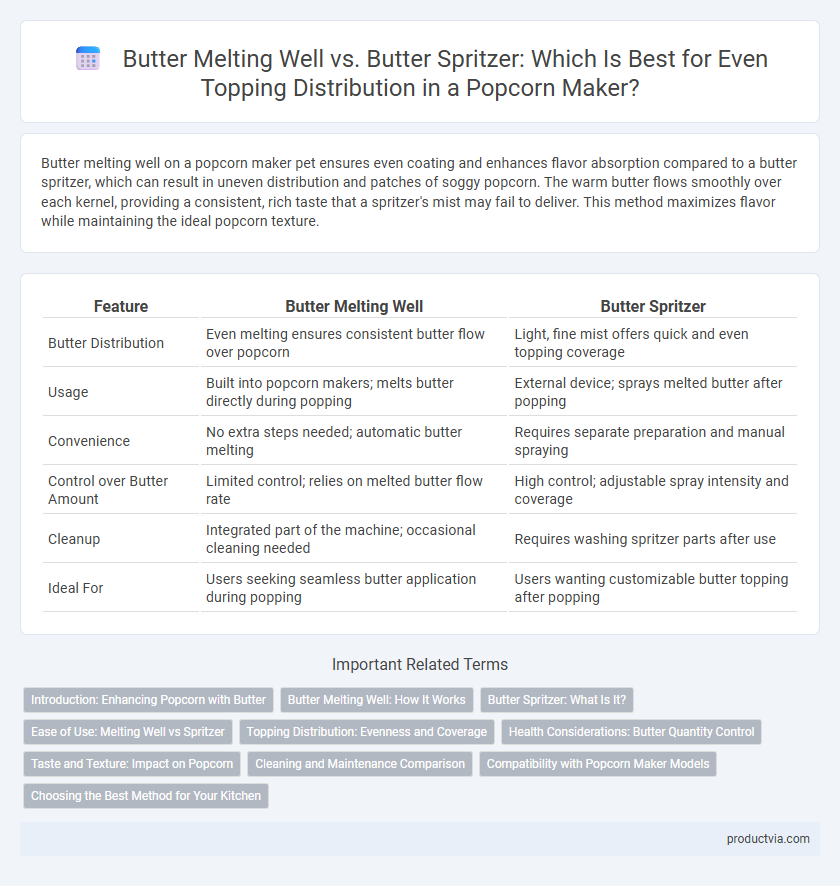

Table of Comparison

| Feature | Butter Melting Well | Butter Spritzer |

|---|---|---|

| Butter Distribution | Even melting ensures consistent butter flow over popcorn | Light, fine mist offers quick and even topping coverage |

| Usage | Built into popcorn makers; melts butter directly during popping | External device; sprays melted butter after popping |

| Convenience | No extra steps needed; automatic butter melting | Requires separate preparation and manual spraying |

| Control over Butter Amount | Limited control; relies on melted butter flow rate | High control; adjustable spray intensity and coverage |

| Cleanup | Integrated part of the machine; occasional cleaning needed | Requires washing spritzer parts after use |

| Ideal For | Users seeking seamless butter application during popping | Users wanting customizable butter topping after popping |

Introduction: Enhancing Popcorn with Butter

Butter melting well on popcorn ensures even coating, enhancing flavor by allowing the butter to seep into every kernel. In contrast, a butter spritzer distributes a fine mist, creating a lighter, more uniform layer without sogginess. Choosing between melted butter and a spritzer depends on preferred texture and flavor intensity for the perfect popcorn experience.

Butter Melting Well: How It Works

Butter melting well features a built-in heating mechanism that maintains butter at an optimal temperature, ensuring it melts evenly and smoothly without burning. This controlled heat allows for consistent butter flow, enhancing popcorn topping distribution compared to a butter spritzer, which can deliver uneven coverage. The steady melting process also preserves the rich flavor and texture, providing a more satisfying popcorn experience.

Butter Spritzer: What Is It?

Butter spritzers are designed to evenly distribute melted butter over popcorn, ensuring each kernel is lightly coated without becoming soggy. Unlike traditional butter melting methods that pour butter in globs, a butter spritzer uses fine misting technology for uniform coverage. This results in a balanced, flavorful popcorn topping that enhances taste and texture while preventing excess grease.

Ease of Use: Melting Well vs Spritzer

Melting butter in a dedicated compartment of a popcorn maker ensures even, consistent coating with minimal effort, eliminating the need for separate preparation. Butter spritzers require additional steps to melt and pour butter before spraying, complicating the topping process. Integrated melting systems enhance ease of use by streamlining butter application and reducing cleanup time.

Topping Distribution: Evenness and Coverage

Butter melting in a popcorn maker ensures smooth, consistent flow, allowing for even topping distribution and thorough coverage over the popcorn surface. In contrast, a butter spritzer tends to create uneven patches due to variable spray patterns, resulting in less uniform flavor dispersion. Optimal topping distribution is achieved when melted butter is applied gradually, maximizing each kernel's exposure to the buttery coating.

Health Considerations: Butter Quantity Control

Using a butter spritzer for topping distribution on popcorn allows precise control over butter quantity, reducing excess saturated fat intake compared to melting butter directly. This method minimizes calorie consumption and supports heart health by avoiding overuse of butter while still providing flavor. Controlled application also prevents greasy popcorn, promoting a lighter and healthier snack option.

Taste and Texture: Impact on Popcorn

Butter melting directly onto popcorn ensures a rich, creamy coating that enhances flavor and creates a smooth, velvety texture, making each kernel evenly indulgent. In contrast, using a butter spritzer results in a lighter, more evenly distributed layer that preserves the popcorn's crispness while delivering a subtle buttery taste. The choice between melted butter and spritzer significantly affects both the taste intensity and the mouthfeel, influencing overall popcorn enjoyment.

Cleaning and Maintenance Comparison

Butter melting well designs ensure even distribution of melted butter, minimizing residue buildup and simplifying cleaning compared to butter spritzers that often leave uneven, oily spots hard to wipe off. Spritzers require frequent disassembly and thorough cleaning to prevent clogging and bacterial growth in nozzles, increasing maintenance time. Overall, butter melting wells provide more efficient topping application with less intensive cleaning, enhancing user convenience and hygiene.

Compatibility with Popcorn Maker Models

Butter melting well offers superior integration with most popcorn maker models featuring built-in warming trays or dedicated butter compartments, ensuring even melting and smooth topping application. Butter spritzers, while convenient for quick butter distribution, may face compatibility issues with certain popcorn makers lacking specialized sprayer attachments, resulting in uneven coverage. Choosing a butter melting system aligned with the popcorn maker's design enhances flavor infusion and prevents clogging or inconsistent butter dispersion.

Choosing the Best Method for Your Kitchen

Butter melting provides rich, evenly distributed flavor by coating popcorn thoroughly, making it ideal for home kitchens seeking a classic taste experience. Butter spritzers offer a lighter and more controlled topping application, minimizing sogginess and enhancing texture, perfect for health-conscious or busy environments. Selecting between melted butter and spritzers depends on desired flavor intensity, ease of use, and kitchen setup efficiency.

Butter melting well vs butter spritzer for topping distribution Infographic

productvia.com

productvia.com