A stirring rod in a popcorn maker pet ensures consistent movement of kernels, promoting even heat distribution and reducing the risk of burning. In contrast, a stationary kettle relies on natural heat conduction, which can cause uneven popping and more unpopped kernels. Choosing a stirring rod mechanism enhances overall popcorn quality by delivering uniform popping and a better texture.

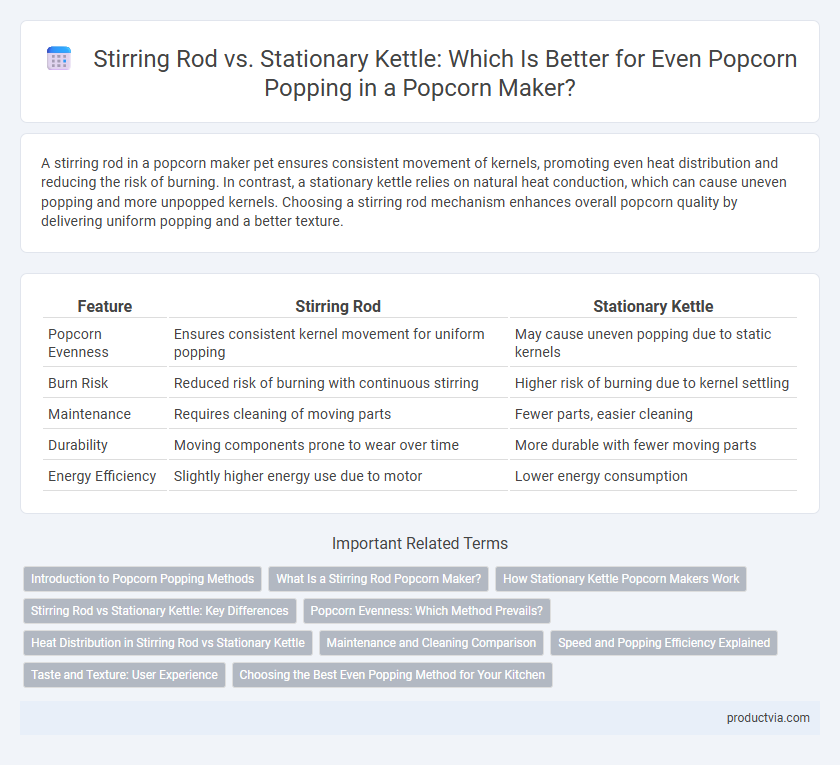

Table of Comparison

| Feature | Stirring Rod | Stationary Kettle |

|---|---|---|

| Popcorn Evenness | Ensures consistent kernel movement for uniform popping | May cause uneven popping due to static kernels |

| Burn Risk | Reduced risk of burning with continuous stirring | Higher risk of burning due to kernel settling |

| Maintenance | Requires cleaning of moving parts | Fewer parts, easier cleaning |

| Durability | Moving components prone to wear over time | More durable with fewer moving parts |

| Energy Efficiency | Slightly higher energy use due to motor | Lower energy consumption |

Introduction to Popcorn Popping Methods

The stirring rod in popcorn makers continuously moves the popcorn kernels to ensure even heat distribution, preventing burning and promoting uniform popping. In contrast, a stationary kettle relies on heat conduction without movement, which can lead to uneven cooking and more unpopped kernels. Choosing between these methods impacts the texture and quality of freshly popped popcorn, with stirring rods generally providing superior consistency.

What Is a Stirring Rod Popcorn Maker?

A stirring rod popcorn maker uses a rotating rod to continuously stir kernels inside the kettle, ensuring even heat distribution and preventing burning. This method enhances popcorn quality by promoting uniform popping and reducing unpopped kernels compared to stationary kettles. Typically favored by commercial vendors, stirring rod models offer consistent results and faster popping times.

How Stationary Kettle Popcorn Makers Work

Stationary kettle popcorn makers use a fixed heating element combined with a warm kettle that evenly distributes heat to the popcorn kernels without the need for a stirring rod. The stationary kettle relies on continuous heat conduction and convection, allowing kernels to pop uniformly at a controlled temperature while preventing burning. This method ensures consistent popping by maintaining steady heat and avoiding mechanical agitation, resulting in a classic texture and flavor profile.

Stirring Rod vs Stationary Kettle: Key Differences

Stirring rod popcorn makers use a rotating arm to continuously move kernels, ensuring even heat distribution and reducing the risk of burning. Stationary kettles rely on heat conduction without movement, which can cause uneven popping and more unpopped kernels. The stirring rod model provides consistent agitation, resulting in higher popping efficiency and a fluffier texture.

Popcorn Evenness: Which Method Prevails?

Stirring rods in popcorn makers ensure continuous movement of kernels, reducing the risk of uneven heating and burnt spots, resulting in consistently popped corn. Stationary kettles rely on heat distribution alone, which can create hotspots and leave some kernels unpopped or burnt. For optimal popcorn evenness, stirring rod mechanisms generally prevail by promoting uniform agitation and heat exposure.

Heat Distribution in Stirring Rod vs Stationary Kettle

Stirring rod popcorn makers provide superior heat distribution by continuously moving kernels, preventing hotspots and ensuring uniform popping. Stationary kettles rely on static heat, often causing uneven cooking and burnt kernels due to inconsistent temperature exposure. Efficient heat transfer in stirring rod systems enhances popcorn texture and reduces unpopped seeds.

Maintenance and Cleaning Comparison

Stirring rod popcorn makers require regular cleaning to prevent residue buildup on the moving parts, which can be more time-consuming compared to stationary kettle models. Stationary kettles have fewer mechanical components, leading to simpler maintenance and easier access for thorough cleaning. Both designs benefit from non-stick coatings, but stationary kettles typically offer a more straightforward and less frequent cleaning process overall.

Speed and Popping Efficiency Explained

A stirring rod in a popcorn maker continuously agitates kernels, promoting rapid and uniform heat distribution that accelerates popping speed and maximizes efficiency by reducing unpopped kernels. In contrast, stationary kettles rely solely on conductive heat transfer, often resulting in uneven heating and slower popping times. Manufacturers report that models equipped with stirring rods achieve up to 30% faster popping cycles and improve overall popcorn yield compared to stationary kettle designs.

Taste and Texture: User Experience

A stirring rod in a popcorn maker consistently agitates kernels, promoting uniform heat distribution that enhances popcorn taste and texture with fewer burnt pieces and more even popping. Stationary kettles rely on heat circulation without movement, often resulting in uneven cooking and a higher chance of chewy or burnt kernels. Users typically prefer stirring rod models for a crispier, fluffier popcorn experience with superior flavor retention.

Choosing the Best Even Popping Method for Your Kitchen

A stirring rod in popcorn makers continuously moves the kernels, ensuring even heat distribution and reducing the risk of burning, which results in consistently popped, fluffy popcorn. In contrast, a stationary kettle relies on manual shaking or heat convection, potentially causing uneven popping and more unpopped kernels. Selecting a popcorn maker with a stirring rod is ideal for users seeking efficient, uniform popping and minimal waste in their kitchen.

Stirring rod vs stationary kettle for even popcorn popping Infographic

productvia.com

productvia.com