A heavy-duty motor in a popcorn maker delivers higher torque and sustained power, enabling it to handle larger popcorn volumes without overheating or slowing down. Compared to a standard motor, it ensures more consistent popping performance and reduces the risk of unpopped kernels. Investing in a heavy-duty motor results in faster, more efficient popcorn production, ideal for frequent or large-batch use.

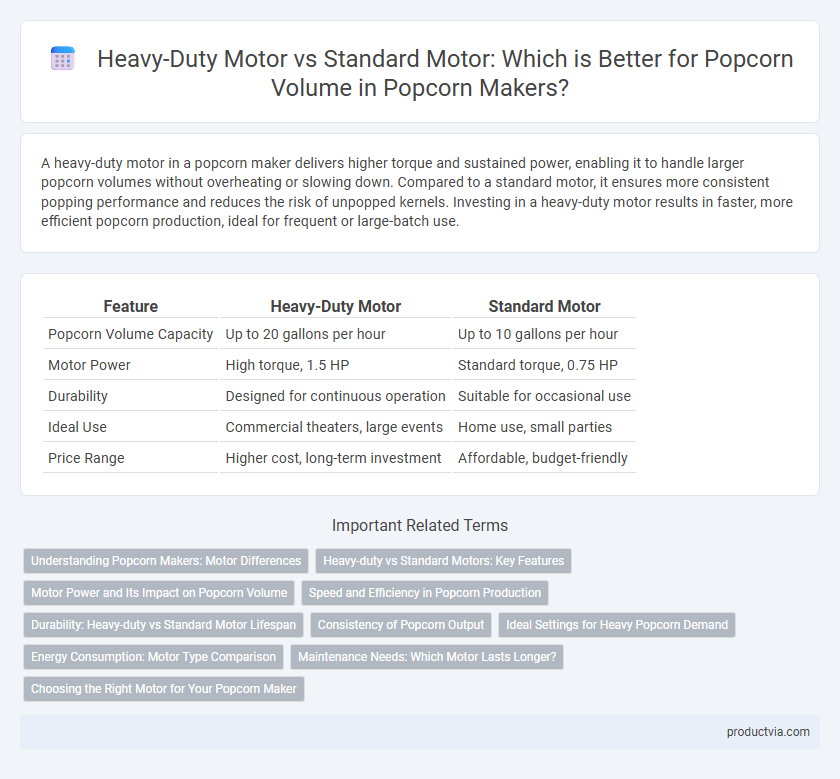

Table of Comparison

| Feature | Heavy-Duty Motor | Standard Motor |

|---|---|---|

| Popcorn Volume Capacity | Up to 20 gallons per hour | Up to 10 gallons per hour |

| Motor Power | High torque, 1.5 HP | Standard torque, 0.75 HP |

| Durability | Designed for continuous operation | Suitable for occasional use |

| Ideal Use | Commercial theaters, large events | Home use, small parties |

| Price Range | Higher cost, long-term investment | Affordable, budget-friendly |

Understanding Popcorn Makers: Motor Differences

Heavy-duty motors in popcorn makers provide higher RPMs and greater torque, enabling faster popping and increased popcorn volume compared to standard motors. They handle larger batches efficiently, reducing un-popped kernels and ensuring consistent heat distribution throughout the popping process. Choosing a popcorn maker with a heavy-duty motor significantly enhances performance and popcorn yield for both commercial and home use.

Heavy-duty vs Standard Motors: Key Features

Heavy-duty motors in popcorn makers deliver higher torque and power, enabling consistent popping of larger popcorn volumes without overheating or stalling. Standard motors often struggle with prolonged use under heavy loads, resulting in slower popping speed and uneven kernels. Choosing a heavy-duty motor ensures durability, efficient heat distribution, and increased popping capacity for commercial or high-demand settings.

Motor Power and Its Impact on Popcorn Volume

Heavy-duty motors in popcorn makers typically range from 500 to 1200 watts, delivering higher torque that efficiently pops a larger volume of kernels per batch compared to standard motors, which usually operate between 300 to 600 watts. Increased motor power accelerates the stirring mechanism, ensuring even heat distribution and reducing unpopped kernels, directly boosting popcorn yield. Selecting a popcorn maker with a robust motor enhances operational efficiency and maximizes popcorn volume during continuous or commercial use.

Speed and Efficiency in Popcorn Production

Heavy-duty motors in popcorn makers deliver faster popping speeds and higher efficiency, enabling the production of larger popcorn volumes in less time compared to standard motors. These powerful motors maintain consistent heat distribution and reduce the risk of kernels burning, ensuring maximum kernel conversion. Investing in a heavy-duty motor significantly enhances popcorn output, ideal for commercial or high-demand environments.

Durability: Heavy-duty vs Standard Motor Lifespan

A heavy-duty motor in a popcorn maker significantly outlasts a standard motor, offering enhanced durability for frequent, high-volume use. Heavy-duty motors are engineered with reinforced components and superior materials, ensuring reliable performance over extended periods. Standard motors, while adequate for occasional use, tend to wear out faster under continuous operation, limiting the lifespan and consistency of popcorn production.

Consistency of Popcorn Output

Heavy-duty motors in popcorn makers provide more consistent popcorn output by maintaining steady rotation speed, ensuring even heating and thorough kernel popping. Standard motors often struggle with uniformity, leading to unevenly popped kernels and irregular batch sizes. Consistency in popcorn volume is significantly improved with heavy-duty motors, which are better suited for high-demand or commercial use.

Ideal Settings for Heavy Popcorn Demand

Heavy-duty motors in popcorn makers deliver higher wattage ranging from 150 to 200 watts, enabling continuous operation without overheating, which is essential for producing large volumes of popcorn quickly. These motors maintain consistent heat distribution and spinning speed, ensuring kernels pop uniformly and reducing unpopped kernels in high-demand settings such as theaters or large events. Standard motors, typically around 100 watts, may overheat or slow down under heavy use, making heavy-duty motors ideal for settings requiring efficient and sustained popcorn production.

Energy Consumption: Motor Type Comparison

Heavy-duty motors in popcorn makers consume more energy but deliver higher popcorn volume, making them ideal for commercial use. Standard motors offer lower energy consumption and are suitable for home use with moderate popcorn production. Choosing between motor types depends on balancing energy efficiency and desired popcorn output.

Maintenance Needs: Which Motor Lasts Longer?

Heavy-duty motors in popcorn makers are specifically engineered for extended use and high popcorn volumes, offering superior durability and reduced maintenance compared to standard motors. These motors have robust components that resist wear and overheating, significantly prolonging operational life and minimizing the frequency of repairs. In contrast, standard motors tend to experience quicker degradation under continuous use, leading to more frequent maintenance and shorter lifespan.

Choosing the Right Motor for Your Popcorn Maker

Heavy-duty motors in popcorn makers deliver higher power output, enabling faster popping and increased popcorn volume compared to standard motors. This robust performance reduces popping time and improves kernel yield, ideal for large batches and frequent use. Selecting a motor with sufficient torque and wattage ensures consistent popping efficiency and durability for heavy popcorn demands.

Heavy-duty motor vs standard motor for popcorn volume Infographic

productvia.com

productvia.com