Stainless steel kettles offer superior durability and corrosion resistance compared to aluminum kettles, making them ideal for consistent heat distribution in popcorn makers. Aluminum kettles heat up quickly and provide excellent thermal conductivity, but they may warp or degrade over time with repeated use. Choosing stainless steel ensures even cooking temperatures and long-lasting performance for perfectly popped popcorn every time.

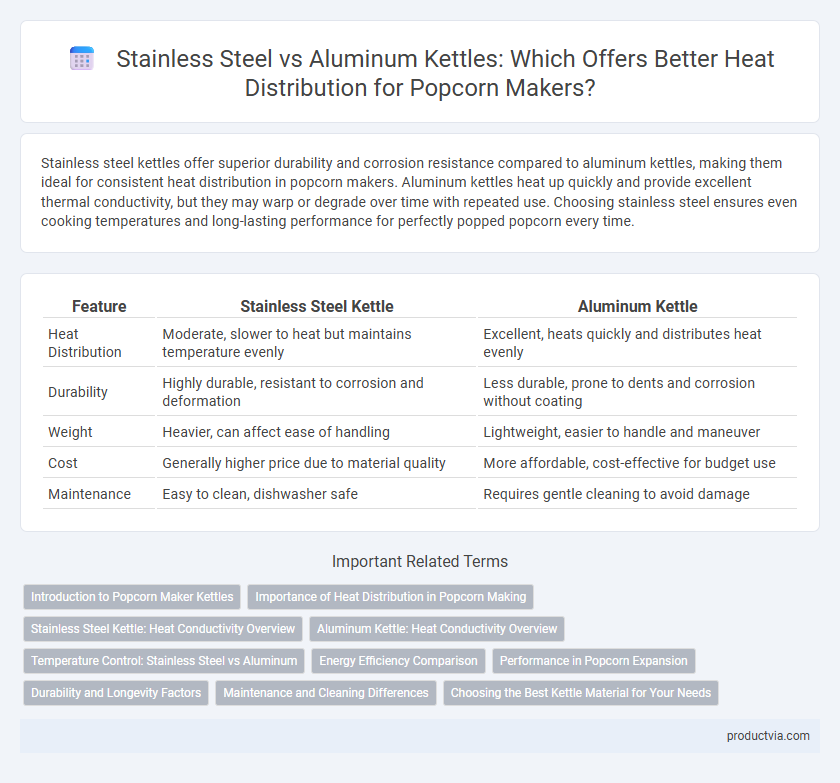

Table of Comparison

| Feature | Stainless Steel Kettle | Aluminum Kettle |

|---|---|---|

| Heat Distribution | Moderate, slower to heat but maintains temperature evenly | Excellent, heats quickly and distributes heat evenly |

| Durability | Highly durable, resistant to corrosion and deformation | Less durable, prone to dents and corrosion without coating |

| Weight | Heavier, can affect ease of handling | Lightweight, easier to handle and maneuver |

| Cost | Generally higher price due to material quality | More affordable, cost-effective for budget use |

| Maintenance | Easy to clean, dishwasher safe | Requires gentle cleaning to avoid damage |

Introduction to Popcorn Maker Kettles

Popcorn maker kettles typically come in stainless steel or aluminum, each affecting heat distribution differently. Stainless steel kettles offer durability and even heat retention, preventing hot spots for uniform popcorn popping. Aluminum kettles conduct heat faster, providing quick and efficient heating, but may result in less consistent temperature control compared to stainless steel.

Importance of Heat Distribution in Popcorn Making

Stainless steel kettles provide more consistent heat distribution in popcorn making, reducing the risk of hot spots that can cause burning or uneven popping. Aluminum kettles heat up quickly and distribute heat effectively but may retain less uniform heat compared to stainless steel. Optimal heat distribution ensures all kernels pop evenly, maximizing yield and maintaining popcorn quality.

Stainless Steel Kettle: Heat Conductivity Overview

Stainless steel kettles offer moderate heat conductivity, ensuring even and consistent heat distribution ideal for controlled popcorn popping. Unlike aluminum kettles, stainless steel maintains durability and resists warping under high temperatures, providing long-lasting performance. The lower thermal conductivity of stainless steel requires slightly longer heating times but contributes to better pop quality by preventing hot spots.

Aluminum Kettle: Heat Conductivity Overview

Aluminum kettles in popcorn makers provide superior heat conductivity, ensuring rapid and even heat distribution across the entire cooking surface. This efficient thermal transfer minimizes hot spots, reducing the risk of burnt kernels and promoting consistent popping performance. Unlike stainless steel, aluminum's lightweight nature enhances quick heating, making it a preferred choice for optimal heat conduction in popcorn preparation.

Temperature Control: Stainless Steel vs Aluminum

Stainless steel kettles provide more consistent temperature control due to their slower heat conductivity, allowing for even popping and reduced risk of burning. Aluminum kettles heat up quickly, offering rapid temperature changes but can create hot spots that affect uniform heat distribution. Choosing stainless steel enhances precision in temperature regulation, while aluminum prioritizes speed but may compromise even heat control.

Energy Efficiency Comparison

Stainless steel kettles provide more uniform heat distribution, enhancing energy efficiency by reducing hot spots and preventing burning during popcorn popping. Aluminum kettles heat up quickly and offer excellent thermal conductivity but may lose heat faster, resulting in potentially higher energy consumption. Choosing a stainless steel kettle can lead to more consistent cooking temperatures and optimized energy use despite a slightly longer heat-up time.

Performance in Popcorn Expansion

Stainless steel kettles provide even heat distribution but generally heat up slower compared to aluminum kettles, which offer rapid and uniform heat conduction essential for consistent popcorn expansion. Aluminum's superior thermal conductivity ensures kernels pop more evenly and fully, reducing unpopped kernels and maximizing expansion. Popcorn makers with aluminum kettles typically deliver better performance in achieving optimal popcorn fluffiness and volume.

Durability and Longevity Factors

Stainless steel kettles offer superior durability and resistance to corrosion compared to aluminum kettles, making them ideal for long-term use in popcorn makers. While aluminum kettles provide faster heat distribution due to their lightweight nature, stainless steel kettles ensure even heating and maintain structural integrity over extended use. The robust composition of stainless steel contributes to greater longevity, reducing the risk of warping or damage under frequent high-heat conditions.

Maintenance and Cleaning Differences

Stainless steel kettles offer superior durability and resist corrosion, making them easier to maintain with simple cleaning materials, while aluminum kettles require more careful handling to avoid scratches and discoloration. Aluminum heats up faster but tends to accumulate residues that demand more frequent and thorough cleaning to prevent flavor contamination. Regular maintenance of stainless steel kettles involves less effort and reduces the risk of metal leaching, contributing to a safer and longer-lasting popcorn maker performance.

Choosing the Best Kettle Material for Your Needs

Stainless steel kettles offer superior durability and even heat distribution, making them ideal for consistent popcorn popping without hot spots. Aluminum kettles heat up faster due to their high thermal conductivity but may require more careful temperature control to avoid burning. Selecting the best kettle material depends on balancing heat distribution efficiency with maintenance preferences and the desired popping consistency.

Stainless steel kettle vs aluminum kettle for heat distribution Infographic

productvia.com

productvia.com