Manual crank popcorn makers require hands-on effort to turn the crank, ensuring even kernel movement and preventing burning through consistent agitation. Automatic agitator models use a motorized stirring mechanism to continuously move kernels, providing uniform heat distribution without manual labor. Choosing between the two depends on preference for control and interaction versus convenience and ease of use.

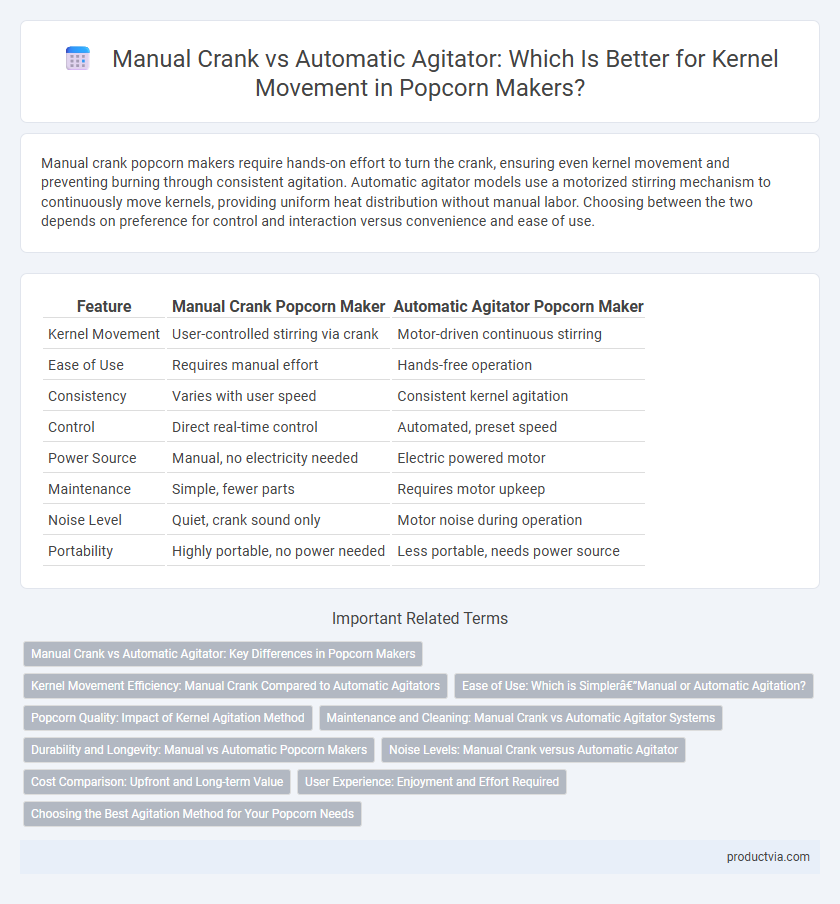

Table of Comparison

| Feature | Manual Crank Popcorn Maker | Automatic Agitator Popcorn Maker |

|---|---|---|

| Kernel Movement | User-controlled stirring via crank | Motor-driven continuous stirring |

| Ease of Use | Requires manual effort | Hands-free operation |

| Consistency | Varies with user speed | Consistent kernel agitation |

| Control | Direct real-time control | Automated, preset speed |

| Power Source | Manual, no electricity needed | Electric powered motor |

| Maintenance | Simple, fewer parts | Requires motor upkeep |

| Noise Level | Quiet, crank sound only | Motor noise during operation |

| Portability | Highly portable, no power needed | Less portable, needs power source |

Manual Crank vs Automatic Agitator: Key Differences in Popcorn Makers

Manual crank popcorn makers require users to physically turn a handle to keep kernels moving, ensuring even heat distribution and reducing the risk of burning. Automatic agitator models feature built-in motorized components that continuously stir kernels for consistent popping without manual effort. The choice between manual crank and automatic agitator depends on user preference for control and convenience during the popcorn-making process.

Kernel Movement Efficiency: Manual Crank Compared to Automatic Agitators

Manual crank popcorn makers offer direct control over kernel movement, ensuring even heat distribution and reducing kernel scorching for a consistent pop. Automatic agitators use mechanical arms or paddles to continuously stir kernels, promoting uniform exposure to heat and minimizing unpopped kernels. While manual cranks allow personalized speed adjustment, automatic agitators provide consistent agitation without user intervention, enhancing overall kernel movement efficiency and popcorn quality.

Ease of Use: Which is Simpler—Manual or Automatic Agitation?

Manual crank popcorn makers offer straightforward control, allowing users to rotate the crank at their own pace, which requires physical effort but provides a hands-on experience. Automatic agitator popcorn machines use motor-driven paddles to continuously stir kernels, ensuring consistent movement and reducing the need for user intervention. For ease of use, automatic agitators are simpler because they eliminate manual labor and ensure even kernel popping without constant attention.

Popcorn Quality: Impact of Kernel Agitation Method

Manual crank popcorn makers offer precise control over kernel agitation, resulting in evenly popped kernels with minimal burning and optimal fluffy texture. Automatic agitators ensure consistent and continuous kernel movement, reducing hot spots and promoting uniform heat distribution for high-quality popcorn batches. The choice between manual and automatic agitation directly influences kernel expansion, texture, and overall popcorn quality.

Maintenance and Cleaning: Manual Crank vs Automatic Agitator Systems

Manual crank popcorn makers offer simplified maintenance and easier cleaning due to fewer mechanical parts that can accumulate residue, requiring only periodic wiping and oiling. Automatic agitator systems involve more complex mechanisms, making them prone to clogging and necessitating regular disassembly and thorough cleaning to prevent kernel debris buildup. Choosing a manual crank model minimizes downtime associated with cleaning, enhancing long-term usability and reliability.

Durability and Longevity: Manual vs Automatic Popcorn Makers

Manual crank popcorn makers offer enhanced durability due to their simpler mechanical design, reducing the risk of motor failure and wear over time. Automatic agitator models rely on electric motors that may experience diminished performance or require repairs after extended use. For long-term reliability, manual crank machines typically provide superior longevity with less frequent maintenance.

Noise Levels: Manual Crank versus Automatic Agitator

Manual crank popcorn makers produce minimal noise as kernel movement relies on quiet, hand-powered rotation, preserving a peaceful environment. Automatic agitators generate consistent movement but tend to emit noticeable motor sounds, which may be distracting in quiet settings. Choosing manual crank options enhances noise-sensitive spaces, while automatic agitators offer convenience at the expense of increased operational noise.

Cost Comparison: Upfront and Long-term Value

Manual crank popcorn makers have a lower upfront cost, making them more accessible for budget-conscious consumers, while requiring physical effort to turn the handle for kernel movement. Automatic agitator models involve higher initial investment but offer consistent kernel stirring and reduced user fatigue, enhancing long-term convenience and efficiency. Evaluating total cost of ownership, including maintenance and electricity usage, often reveals automatic agitators deliver better value through improved popping performance and time savings.

User Experience: Enjoyment and Effort Required

Manual crank popcorn makers engage users by requiring physical effort to turn the crank, providing a tactile and interactive experience that enhances enjoyment but demands continuous attention and moderate exertion. Automatic agitator models reduce user effort by mechanizing kernel movement, allowing for a more hands-off approach that increases convenience and consistency while minimizing fatigue during popcorn preparation. The choice between manual crank and automatic agitator primarily influences the balance between user engagement and ease of operation in popcorn making.

Choosing the Best Agitation Method for Your Popcorn Needs

Manual crank popcorn makers provide precise control over kernel movement, allowing users to adjust speed and intensity to prevent burning and ensure even popping. Automatic agitator systems offer consistent, hands-free kernel agitation using motorized paddles, ideal for larger batches or continuous popping with minimal supervision. Selecting the best agitation method depends on batch size, user preference for control, and desired convenience in popcorn preparation.

Manual crank vs automatic agitator for kernel movement Infographic

productvia.com

productvia.com