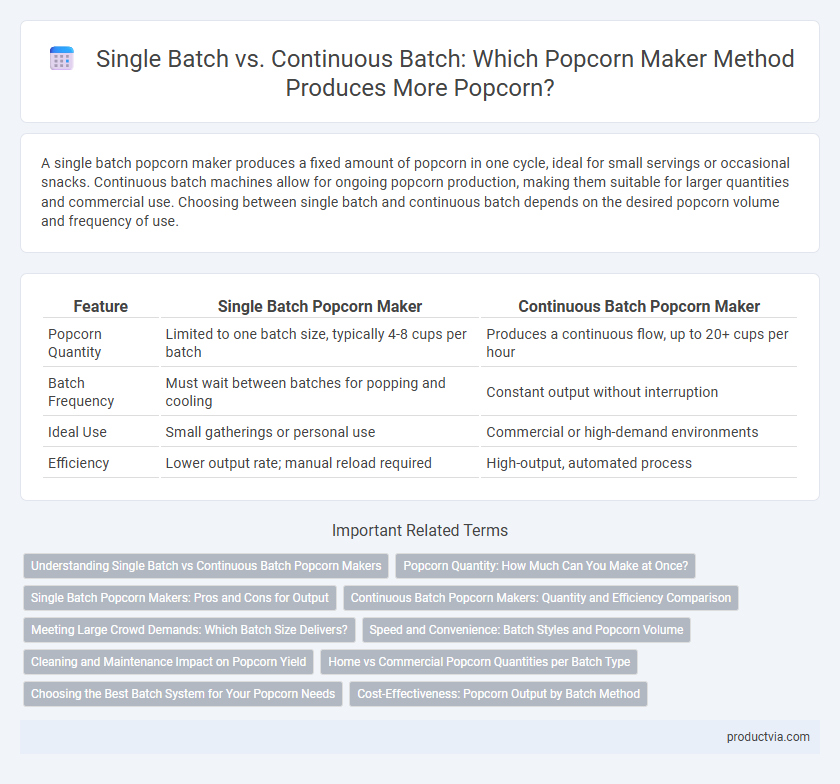

A single batch popcorn maker produces a fixed amount of popcorn in one cycle, ideal for small servings or occasional snacks. Continuous batch machines allow for ongoing popcorn production, making them suitable for larger quantities and commercial use. Choosing between single batch and continuous batch depends on the desired popcorn volume and frequency of use.

Table of Comparison

| Feature | Single Batch Popcorn Maker | Continuous Batch Popcorn Maker |

|---|---|---|

| Popcorn Quantity | Limited to one batch size, typically 4-8 cups per batch | Produces a continuous flow, up to 20+ cups per hour |

| Batch Frequency | Must wait between batches for popping and cooling | Constant output without interruption |

| Ideal Use | Small gatherings or personal use | Commercial or high-demand environments |

| Efficiency | Lower output rate; manual reload required | High-output, automated process |

Understanding Single Batch vs Continuous Batch Popcorn Makers

Single batch popcorn makers pop one batch at a time, producing a limited quantity ideal for small servings or occasional use, ensuring fresh popcorn with each batch. Continuous batch popcorn machines allow for ongoing popping, delivering larger volumes suited for commercial or high-demand settings by automatically feeding kernels and ejecting popcorn. Choosing between single and continuous batch depends on desired quantity, frequency of use, and operational scale.

Popcorn Quantity: How Much Can You Make at Once?

Single batch popcorn makers typically produce between 4 to 8 cups of popcorn per cycle, making them ideal for small to medium servings. Continuous batch popcorn makers can produce significantly larger quantities, often up to 100 cups or more per hour, catering to high-traffic environments or commercial use. The choice between single and continuous batch models depends largely on the required popcorn quantity and frequency of use.

Single Batch Popcorn Makers: Pros and Cons for Output

Single batch popcorn makers typically produce smaller quantities per cycle, making them ideal for home use or small gatherings where fresh popcorn is preferred. These machines ensure consistent heat distribution, resulting in better flavor and fewer unpopped kernels compared to continuous batch models. However, the downtime required between batches can limit total output during large events or commercial use.

Continuous Batch Popcorn Makers: Quantity and Efficiency Comparison

Continuous batch popcorn makers significantly outperform single batch models by producing a higher quantity of popcorn without interruption, ideal for commercial environments requiring consistent output. Their efficient design allows continuous loading and popping of kernels, resulting in increased productivity and reduced downtime. This makes continuous batch machines a preferred choice for large-scale events and businesses where volume and speed are critical.

Meeting Large Crowd Demands: Which Batch Size Delivers?

Single batch popcorn makers produce a fixed quantity per cycle, ideal for small to medium gatherings but potentially time-consuming for large crowds due to repeated batches. Continuous batch machines efficiently handle high-volume demands by popping consistently without interruption, ensuring a steady supply of fresh popcorn. For events requiring rapid service and large quantities, continuous batch systems outperform single batch models in meeting crowd demands.

Speed and Convenience: Batch Styles and Popcorn Volume

Single batch popcorn makers produce a fixed amount of popcorn per cycle, offering precise portion control but requiring time between batches for cooling and resetting. Continuous batch poppers maintain a steady popcorn flow, ideal for high-volume needs with minimal downtime, enhancing speed and convenience. For large gatherings or commercial use, continuous batch machines maximize output, while single batch models suit smaller, casual servings.

Cleaning and Maintenance Impact on Popcorn Yield

Single batch popcorn makers require frequent cleaning between uses, which can temporarily reduce popcorn yield due to downtime and residue buildup. Continuous batch machines promote higher popcorn yield by allowing uninterrupted production while minimizing residue accumulation through streamlined cleaning processes. Efficient maintenance schedules for continuous batch systems lead to consistent popcorn quality and maximize overall output.

Home vs Commercial Popcorn Quantities per Batch Type

Single batch popcorn makers typically produce between 4 to 8 cups per cycle, ideal for home use where small quantities are preferred for freshness and convenience. Continuous batch popcorn machines, commonly found in commercial settings, can produce upwards of 50 to 100 cups per hour, efficiently meeting high demand in theaters and concession stands. Home popcorn makers prioritize quality and portion control, while commercial models focus on volume and speed to accommodate large audiences.

Choosing the Best Batch System for Your Popcorn Needs

Single batch popcorn makers handle one portion at a time, ideal for small quantities and precise control over popping consistency. Continuous batch systems process large volumes without interruption, perfect for high-demand settings and maximizing output efficiency. Selecting the best batch system depends on your popcorn quantity requirements and operational scale, balancing convenience with production capacity.

Cost-Effectiveness: Popcorn Output by Batch Method

Single batch popcorn makers typically produce smaller quantities, making them cost-effective for low-volume use by minimizing waste and energy consumption per batch. Continuous batch machines offer higher popcorn output suitable for large-scale operations, reducing labor costs but potentially increasing energy expenses. Choosing between single and continuous batch methods depends on balancing popcorn demand with operational efficiency to optimize cost-effectiveness.

Single batch vs continuous batch for popcorn quantity Infographic

productvia.com

productvia.com