Choosing a single-batch popcorn maker pet offers precise control over portion size, ensuring freshness with each batch, making it ideal for small groups or personalized servings. Continuous popcorn poppers accommodate large servings efficiently by producing popcorn nonstop, perfect for gatherings or parties where volume and speed are priorities. For feeding a crowd, continuous poppers deliver convenience and quantity, while single-batch units emphasize quality and customization.

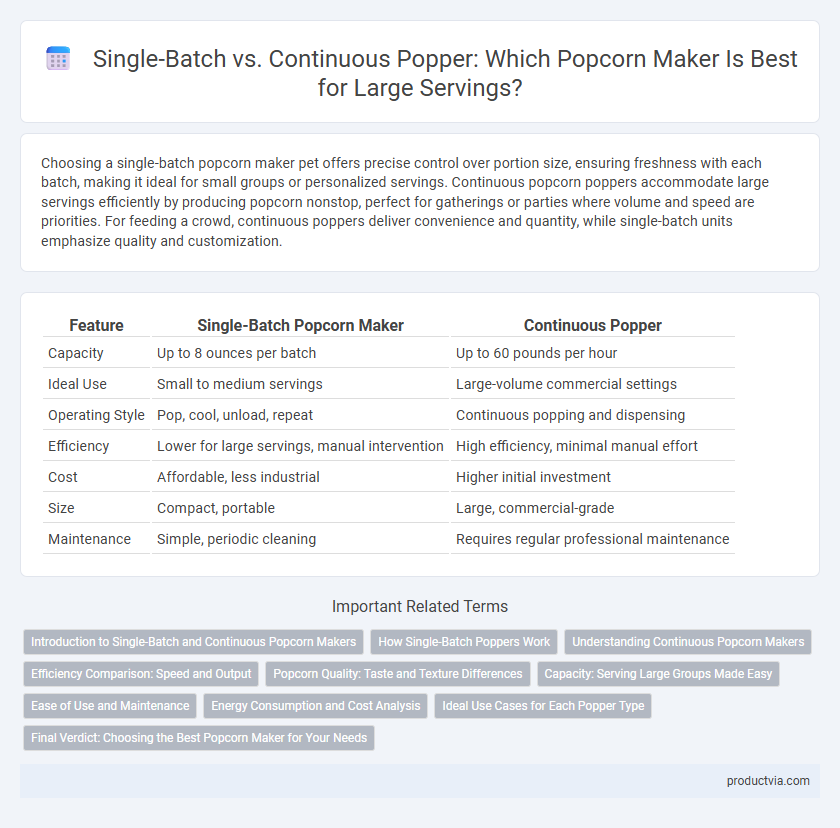

Table of Comparison

| Feature | Single-Batch Popcorn Maker | Continuous Popper |

|---|---|---|

| Capacity | Up to 8 ounces per batch | Up to 60 pounds per hour |

| Ideal Use | Small to medium servings | Large-volume commercial settings |

| Operating Style | Pop, cool, unload, repeat | Continuous popping and dispensing |

| Efficiency | Lower for large servings, manual intervention | High efficiency, minimal manual effort |

| Cost | Affordable, less industrial | Higher initial investment |

| Size | Compact, portable | Large, commercial-grade |

| Maintenance | Simple, periodic cleaning | Requires regular professional maintenance |

Introduction to Single-Batch and Continuous Popcorn Makers

Single-batch popcorn makers produce popcorn in discrete portions, ideal for controlled serving sizes and minimal waste. Continuous popcorn poppers operate by continuously heating kernels, perfect for large-scale events requiring constant supply and faster output. Choosing between single-batch and continuous systems depends on volume needs, serving speed, and product freshness priorities.

How Single-Batch Poppers Work

Single-batch popcorn makers operate by heating a fixed amount of kernels in a single container until they pop, offering precise control over portion size and cooking time. These machines typically feature a heating element and stirring mechanism to evenly distribute heat and prevent burning, ensuring consistent quality for each batch. Ideal for controlled servings, single-batch poppers excel in maintaining kernel freshness and maximizing flavor for large servings when used repeatedly.

Understanding Continuous Popcorn Makers

Continuous popcorn makers offer efficient handling of large servings by allowing nonstop popcorn production, which significantly reduces wait times during busy events. These machines typically feature automated kernels feeding and butter dispensing systems, maintaining consistent quality and portion control. Their design supports scalable popcorn output, making them ideal for venues requiring sustained high-volume service.

Efficiency Comparison: Speed and Output

Single-batch popcorn makers typically produce smaller quantities per cycle, leading to longer overall preparation times for large servings. Continuous poppers offer superior efficiency with rapid, nonstop popping, delivering higher output rates ideal for large-scale events. This speed and volume advantage make continuous poppers the preferred choice for catering and commercial use.

Popcorn Quality: Taste and Texture Differences

Single-batch popcorn makers typically produce superior taste and texture due to even heat distribution and controlled popping, resulting in fluffier, crisp kernels with fewer unpopped seeds. Continuous poppers prioritize volume and speed, often leading to unevenly popped kernels and a slightly tougher texture because of prolonged heat exposure. For large servings, the choice between single-batch and continuous poppers significantly impacts popcorn quality, with single-batch models favored for optimal flavor and freshness.

Capacity: Serving Large Groups Made Easy

Single-batch popcorn makers typically handle one batch at a time, making them ideal for small gatherings but less efficient for large groups due to limited capacity. Continuous poppers offer high-capacity output, providing a steady stream of freshly popped popcorn ideal for events with significant guest counts. Their design supports uninterrupted popping, ensuring large servings are prepared quickly and with consistent quality.

Ease of Use and Maintenance

Single-batch popcorn makers offer straightforward operation and quick cleanup, making them ideal for ease of use in serving large quantities in multiple cycles. Continuous poppers handle larger volumes without interruption, but their complex mechanisms require more maintenance and cleaning effort. Choosing between the two depends on balancing the convenience of simpler batch processing against the higher capacity but increased upkeep of continuous machines.

Energy Consumption and Cost Analysis

Single-batch popcorn makers consume less energy per batch but require multiple cycles for large servings, increasing overall operational time and labor costs. Continuous poppers use more power upfront but offer lower energy consumption per volume due to efficiency in handling large quantities nonstop. Cost analysis reveals that continuous poppers reduce per-serving expenses in high-demand environments despite higher initial investment, while single-batch machines suit low to moderate volume needs with lower upfront costs.

Ideal Use Cases for Each Popper Type

Single-batch popcorn makers excel in small to medium servings, offering precise control over each batch's quality and freshness, ideal for home use or small events. Continuous poppers are designed for large servings, producing popcorn nonstop to meet high demand efficiently, making them perfect for commercial use, theaters, and large parties. Understanding these use cases helps select the right popper based on serving volume and operational needs.

Final Verdict: Choosing the Best Popcorn Maker for Your Needs

Single-batch popcorn makers excel in producing smaller, fresher servings ideal for home use or occasional snacking, offering precise control over popping quality. Continuous poppers, designed for high-volume output, efficiently supply large crowds without downtime, making them perfect for events or commercial use. Selecting the best popcorn maker ultimately depends on balancing serving size demands, frequency of use, and ease of operation to meet your specific popcorn preparation needs.

Single-batch vs Continuous Popper for Large Servings Infographic

productvia.com

productvia.com