The Gasket Release System offers a reliable pressure relief by allowing excess steam to escape through the gasket when pressure exceeds safe levels, preventing dangerous buildup inside the cooker. In contrast, the Fusible Plug acts as a fail-safe by melting at a predetermined temperature to release pressure, providing a secondary safety measure in case the primary system fails. Both mechanisms play crucial roles in ensuring pressure cooker safety, but the gasket release system typically provides quicker response to pressure changes.

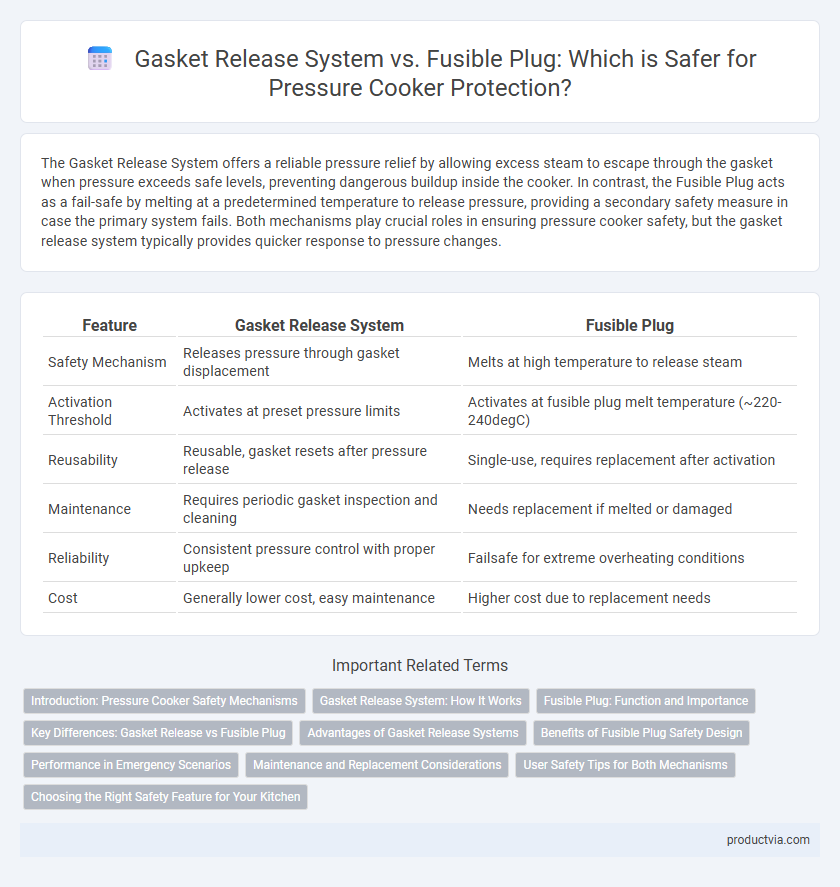

Table of Comparison

| Feature | Gasket Release System | Fusible Plug |

|---|---|---|

| Safety Mechanism | Releases pressure through gasket displacement | Melts at high temperature to release steam |

| Activation Threshold | Activates at preset pressure limits | Activates at fusible plug melt temperature (~220-240degC) |

| Reusability | Reusable, gasket resets after pressure release | Single-use, requires replacement after activation |

| Maintenance | Requires periodic gasket inspection and cleaning | Needs replacement if melted or damaged |

| Reliability | Consistent pressure control with proper upkeep | Failsafe for extreme overheating conditions |

| Cost | Generally lower cost, easy maintenance | Higher cost due to replacement needs |

Introduction: Pressure Cooker Safety Mechanisms

Pressure cookers incorporate safety features such as the gasket release system and the fusible plug to prevent excessive pressure buildup. The gasket release system uses a flexible sealing ring that allows steam to escape when pressure exceeds safe limits, ensuring controlled pressure relief. The fusible plug contains a low-melting-point alloy that melts under extreme heat, providing a fail-safe mechanism to release pressure and prevent potential explosions.

Gasket Release System: How It Works

The Gasket Release System in pressure cookers enhances safety by creating a controlled pressure release through the flexible gasket, which loosens and vents steam when internal pressure exceeds safe limits. This system prevents dangerous pressure buildup by allowing gradual steam escape, reducing the risk of explosions compared to the fusible plug, which melts at a predetermined temperature to release pressure. Its design ensures automatic activation without manual intervention, maintaining consistent cooker performance and user safety during high-pressure cooking.

Fusible Plug: Function and Importance

The fusible plug in a pressure cooker acts as a critical safety device by melting at a predetermined temperature, releasing steam to prevent excessive pressure buildup that could lead to explosions. It functions as a fail-safe mechanism, activating when the primary gasket release system fails, thus ensuring user protection. Its importance lies in its reliability as an irreversible pressure relief component that safeguards both the appliance and the user from hazardous overpressure conditions.

Key Differences: Gasket Release vs Fusible Plug

The gasket release system in pressure cookers is designed to release steam by displacing the gasket when internal pressure exceeds safe levels, providing a controlled venting mechanism. In contrast, the fusible plug melts at a predetermined temperature, creating an opening to release pressure and prevent explosions. Key differences include the gasket release's reusable, mechanical pressure response versus the fusible plug's one-time, temperature-activated safety function.

Advantages of Gasket Release Systems

Gasket release systems enhance pressure cooker safety by providing a reliable and reusable pressure release mechanism that activates before excessive pressure builds up. Unlike fusible plugs, which require replacement after activation, gasket release systems reset automatically, reducing maintenance costs and downtime. Their design ensures consistent sealing and pressure regulation, improving user safety and cooker longevity.

Benefits of Fusible Plug Safety Design

The fusible plug safety design in pressure cookers offers a reliable thermal release mechanism that melts at a predetermined temperature to prevent excessive pressure buildup, reducing the risk of explosions. Unlike gasket release systems that rely on gasket deformation, the fusible plug ensures a fail-safe response even if the gasket fails or is improperly seated. This design enhances overall cooker safety by providing a precise and automatic pressure relief method, especially valuable in high-temperature cooking scenarios.

Performance in Emergency Scenarios

The Gasket Release System in pressure cookers provides reliable pressure relief by allowing steam to escape through a sealing gasket, ensuring quick venting during emergency overpressure conditions. In contrast, the Fusible Plug relies on a heat-sensitive alloy that melts at a specific temperature, offering a fail-safe release but with slower response time in sudden pressure spikes. Performance in emergency scenarios favors the Gasket Release System for rapid pressure alleviation, while the Fusible Plug serves as a backup to prevent catastrophic failure if the primary system malfunctions.

Maintenance and Replacement Considerations

The Gasket Release System in pressure cookers requires regular inspection and timely replacement of the rubber gasket to ensure an effective seal and prevent steam leaks, typically every 12 to 18 months depending on usage. In contrast, the Fusible Plug is a metal safety component that melts at high temperatures to release pressure, demanding less frequent replacement but necessitating careful checking for signs of corrosion or damage during periodic maintenance. Proper upkeep of both systems is crucial to maintain pressure cooker safety, with gasket maintenance focusing on elasticity and integrity, while fusible plug attention centers on metal condition and melt-point reliability.

User Safety Tips for Both Mechanisms

User safety tips for gasket release systems in pressure cookers include regularly inspecting the gasket for cracks or wear to prevent steam leaks and ensuring the gasket is properly seated before cooking. For fusible plug mechanisms, users should never tamper with or replace the plug themselves, as it is designed to melt and release pressure in extreme conditions, signaling a critical safety issue. Always follow manufacturer guidelines for maintenance and promptly replace worn parts to maintain optimal safety performance.

Choosing the Right Safety Feature for Your Kitchen

The gasket release system provides a reliable pressure relief mechanism by allowing excess steam to escape when pressure exceeds safe limits, ensuring consistent performance without the need for replacement after activation. In contrast, the fusible plug, designed to melt at high temperatures, acts as a fail-safe by permanently releasing pressure to prevent explosions but requires replacement once triggered. Selecting the right safety feature depends on your cooking habits and maintenance preferences, where gasket release systems offer reusable safety, while fusible plugs provide a critical backup in extreme pressure scenarios.

Gasket Release System vs Fusible Plug for Pressure Cooker Safety Infographic

productvia.com

productvia.com