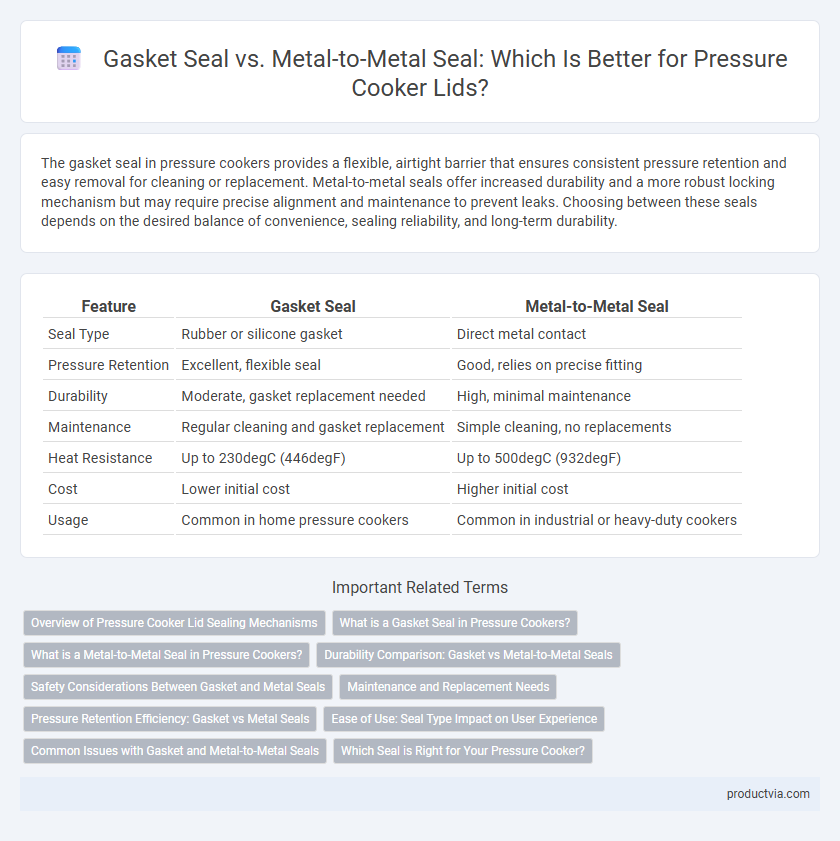

The gasket seal in pressure cookers provides a flexible, airtight barrier that ensures consistent pressure retention and easy removal for cleaning or replacement. Metal-to-metal seals offer increased durability and a more robust locking mechanism but may require precise alignment and maintenance to prevent leaks. Choosing between these seals depends on the desired balance of convenience, sealing reliability, and long-term durability.

Table of Comparison

| Feature | Gasket Seal | Metal-to-Metal Seal |

|---|---|---|

| Seal Type | Rubber or silicone gasket | Direct metal contact |

| Pressure Retention | Excellent, flexible seal | Good, relies on precise fitting |

| Durability | Moderate, gasket replacement needed | High, minimal maintenance |

| Maintenance | Regular cleaning and gasket replacement | Simple cleaning, no replacements |

| Heat Resistance | Up to 230degC (446degF) | Up to 500degC (932degF) |

| Cost | Lower initial cost | Higher initial cost |

| Usage | Common in home pressure cookers | Common in industrial or heavy-duty cookers |

Overview of Pressure Cooker Lid Sealing Mechanisms

Pressure cooker lids utilize two primary sealing mechanisms: gasket seals and metal-to-metal seals. Gasket seals employ a flexible rubber or silicone ring that creates an airtight barrier, ensuring high-pressure retention and easy maintenance. In contrast, metal-to-metal seals rely on precisely machined components that provide durability and a long-lasting seal without the need for replacement parts.

What is a Gasket Seal in Pressure Cookers?

A gasket seal in pressure cookers is a flexible ring, usually made of silicone or rubber, that fits snugly between the lid and the pot to create an airtight seal. This seal is essential for maintaining pressure by preventing steam from escaping during cooking, ensuring efficient heat retention and faster cooking times. Unlike metal-to-metal seals, gasket seals offer enhanced safety and reliability by adapting to minor imperfections on the lid or pot edges.

What is a Metal-to-Metal Seal in Pressure Cookers?

A metal-to-metal seal in pressure cookers refers to a sealing mechanism where the lid and the pot rim create a tight seal through precisely machined metal surfaces, unlike traditional gasket seals that rely on rubber or silicone rings. This seal type enhances durability and heat resistance, reducing wear and the need for frequent gasket replacements. Metal-to-metal seals ensure consistent pressure maintenance, improving cooking efficiency and safety in high-temperature environments.

Durability Comparison: Gasket vs Metal-to-Metal Seals

Gasket seals in pressure cooker lids typically offer excellent airtightness but may wear out or degrade over time, requiring regular replacement to maintain optimal performance. Metal-to-metal seals provide superior durability and resistance to wear, as they rely on precision-machined components that do not deteriorate like rubber or silicone gaskets. For long-term reliability, metal-to-metal seals often outperform gasket seals by maintaining consistent pressure retention without the need for frequent maintenance.

Safety Considerations Between Gasket and Metal Seals

Gasket seals in pressure cookers provide a flexible, airtight barrier that effectively maintains pressure but require regular inspection and replacement to prevent leaks and potential hazards. Metal-to-metal seals offer a durable, long-lasting connection with minimal maintenance, reducing the risk of gasket wear and sudden pressure loss, enhancing safety during high-temperature cooking. Choosing between these seals depends on balancing maintenance frequency, pressure retention efficiency, and the user's attention to safety protocols to prevent accidents.

Maintenance and Replacement Needs

Gasket seals in pressure cooker lids require regular maintenance, including frequent cleaning and periodic replacement every 12 to 18 months to ensure an airtight seal and prevent steam leaks. Metal-to-metal seals offer increased durability with minimal maintenance but may require professional servicing or replacement if deformation or wear occurs. Choosing between the two depends on user preference for ease of upkeep versus long-term durability.

Pressure Retention Efficiency: Gasket vs Metal Seals

Gasket seals provide superior pressure retention in pressure cooker lids by creating an airtight, flexible barrier that prevents steam leakage during cooking cycles. Metal-to-metal seals, while durable and less prone to wear, often exhibit microscopic gaps that reduce pressure retention efficiency and may lead to steam escape. Consistently maintaining pressure improves cooking performance and safety, making gasket seals the preferred choice for optimal pressure retention in pressure cookers.

Ease of Use: Seal Type Impact on User Experience

Gasket seals on pressure cooker lids provide a flexible and secure fit, making them easier for users to align and lock compared to metal-to-metal seals, which often require precise positioning to ensure safety. The rubber or silicone gasket compresses to create an airtight seal, simplifying lid closure and reducing user effort during pressure buildup and release phases. Metal-to-metal seals, while durable and long-lasting, can be less forgiving with misalignment, potentially complicating the sealing process and impacting overall ease of use.

Common Issues with Gasket and Metal-to-Metal Seals

Gasket seals in pressure cooker lids often face common issues such as wear and tear, deformation, and loss of elasticity, leading to steam leaks and pressure loss. Metal-to-metal seals can suffer from warping, corrosion, and imperfect surface mating, causing insufficient sealing and potential safety hazards. Both sealing types require regular maintenance and inspection to ensure optimal performance and prevent accidents during cooking.

Which Seal is Right for Your Pressure Cooker?

The gasket seal offers a flexible, airtight fit ideal for most home pressure cookers, ensuring reliable steam retention and easy maintenance. Metal-to-metal seals provide superior durability and longevity, making them well-suited for heavy-duty or commercial pressure cookers where high pressure and temperature resistance are crucial. Choosing the right seal depends on your cooker model, cooking frequency, and desired balance between convenience and robustness.

Gasket Seal vs Metal-to-Metal Seal for Pressure Cooker Lid Infographic

productvia.com

productvia.com