Gaskets provide a reliable, flexible seal in pressure cookers, accommodating slight surface imperfections and ensuring airtight cooking environments. Metal-to-metal seals, while durable, require precise machining and may not compensate for minor irregularities, risking potential leaks under high pressure. Choosing between gasket and metal-to-metal seals depends on maintenance preferences and the desired balance between ease of use and long-term durability.

Table of Comparison

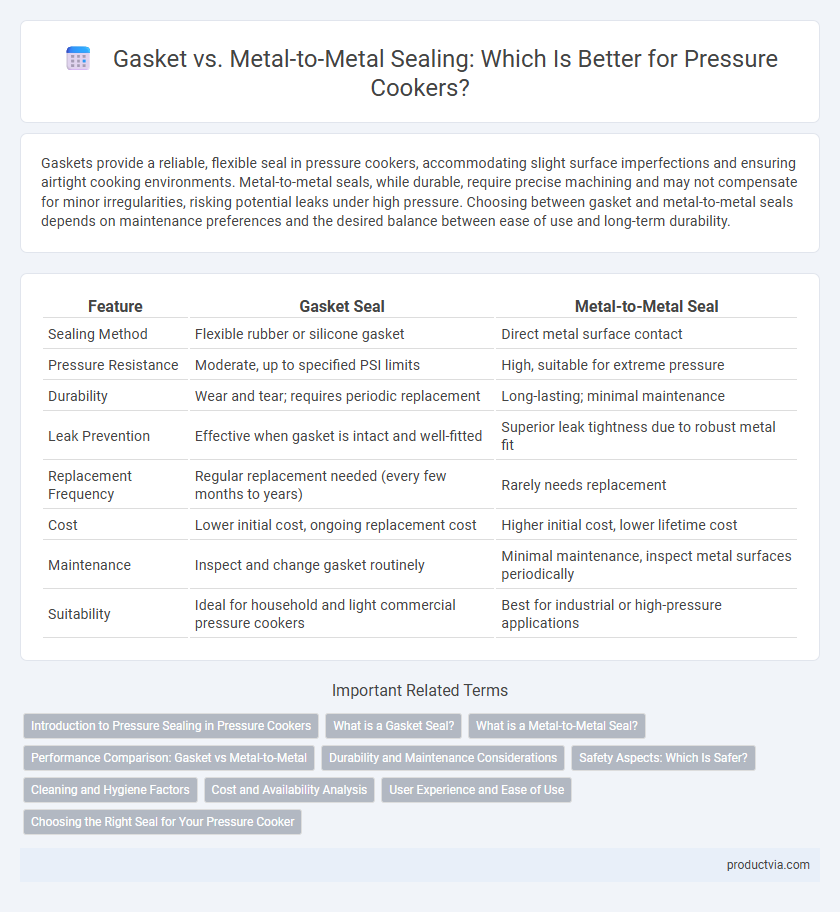

| Feature | Gasket Seal | Metal-to-Metal Seal |

|---|---|---|

| Sealing Method | Flexible rubber or silicone gasket | Direct metal surface contact |

| Pressure Resistance | Moderate, up to specified PSI limits | High, suitable for extreme pressure |

| Durability | Wear and tear; requires periodic replacement | Long-lasting; minimal maintenance |

| Leak Prevention | Effective when gasket is intact and well-fitted | Superior leak tightness due to robust metal fit |

| Replacement Frequency | Regular replacement needed (every few months to years) | Rarely needs replacement |

| Cost | Lower initial cost, ongoing replacement cost | Higher initial cost, lower lifetime cost |

| Maintenance | Inspect and change gasket routinely | Minimal maintenance, inspect metal surfaces periodically |

| Suitability | Ideal for household and light commercial pressure cookers | Best for industrial or high-pressure applications |

Introduction to Pressure Sealing in Pressure Cookers

Pressure sealing in pressure cookers relies on two main mechanisms: gasket-based sealing and metal-to-metal sealing. Gasket seals, typically made of silicone or rubber, provide a flexible, airtight barrier ensuring steam retention and consistent internal pressure. Metal-to-metal seals, often used in industrial pressure cookers, utilize precise machining for a tight, durable seal that withstands higher temperatures and pressures without gasket wear.

What is a Gasket Seal?

A gasket seal in a pressure cooker is a flexible, heat-resistant ring made from silicone or rubber that fits securely between the lid and the pot to create an airtight barrier. This silicone gasket ensures pressure is maintained by preventing steam from escaping during cooking, enhancing safety and efficiency. Unlike metal-to-metal seals, gasket seals offer better adaptability to surface irregularities, providing a reliable and consistent pressure seal.

What is a Metal-to-Metal Seal?

A metal-to-metal seal in pressure cookers involves direct contact between two polished metal surfaces, creating a tight, durable seal without the need for a gasket. This sealing method enhances safety and longevity by eliminating gasket wear and tear, commonly found in silicone or rubber gasket seals. Metal-to-metal seals ensure consistent pressure retention and reduce maintenance, making them ideal for high-performance pressure cookers.

Performance Comparison: Gasket vs Metal-to-Metal

Gasket seals in pressure cookers offer superior flexibility and airtight sealing, effectively preventing steam and pressure leakage during cooking. Metal-to-metal seals provide enhanced durability and resistance to wear but may require precise machining and maintenance to maintain a reliable seal under high pressure. Performance-wise, gasket seals are generally more efficient for consistent pressure retention, while metal-to-metal seals excel in longevity and harsh operating conditions.

Durability and Maintenance Considerations

Gasket pressure seals offer reliable sealing with periodic replacement needed due to wear, making maintenance straightforward but recurring. Metal-to-metal seals provide superior durability and often last longer under high pressure and temperature conditions, reducing the frequency of maintenance. However, metal seals require precise machining and can be more challenging to service compared to gasket seals.

Safety Aspects: Which Is Safer?

Gasket pressure cookers utilize a rubber or silicone ring to create an airtight seal, effectively preventing steam leaks and ensuring consistent pressure, which enhances safety by reducing the risk of explosive failures. Metal-to-metal sealing, often found in high-end or commercial models, provides a durable, wear-resistant connection that minimizes gasket degradation but requires precise engineering to maintain airtightness, potentially increasing the risk of pressure loss if not properly maintained. Overall, gasket seals offer safer and more reliable pressure containment for everyday use due to their flexibility and ease of inspection, while metal-to-metal seals demand rigorous maintenance to match the same safety standards.

Cleaning and Hygiene Factors

Gasket seals in pressure cookers provide better cleanliness by creating a flexible barrier that minimizes food residue buildup and allows easy removal for thorough cleaning. Metal-to-metal seals, while durable, tend to accumulate more grime in grooves and crevices, making hygiene maintenance more challenging. Effective cleaning ensures optimal pressure sealing and prevents contamination, with gasket materials often favored for their hygienic advantages.

Cost and Availability Analysis

Gasket seals offer lower initial costs and are widely available in various materials suitable for most pressure cookers, making them a cost-effective choice for maintenance and replacement. Metal-to-metal seals generally have higher upfront expenses due to precision manufacturing and specialized materials, but they provide durable, long-lasting sealing with reduced replacement frequency. Availability of metal-to-metal seals is more limited, often requiring custom orders or specific manufacturers, whereas gaskets are readily stocked by many suppliers globally.

User Experience and Ease of Use

Gasket seals in pressure cookers provide a more user-friendly experience by ensuring a secure, airtight closure that is easy to check and replace, enhancing safety and maintenance simplicity. Metal-to-metal seals offer durability and high-pressure resistance but require precise alignment and can be more difficult to clean and inspect, potentially complicating daily use. Users often prefer gasket seals for their convenience and reliability during routine cooking tasks.

Choosing the Right Seal for Your Pressure Cooker

Choosing the right seal for your pressure cooker significantly impacts its safety and efficiency. Gasket seals, typically made from silicone or rubber, provide a flexible and airtight closure, ensuring consistent pressure build-up and easy maintenance. Metal-to-metal seals offer durability and are ideal for high-pressure cooking but require precise machining to maintain a secure seal without leaks.

Gasket vs Metal-to-metal for pressure sealing Infographic

productvia.com

productvia.com