Pressure cooker pets with an anodized finish offer superior durability and resistance to corrosion compared to non-anodized finishes, ensuring long-lasting performance under high heat and pressure. The anodized layer creates a harder surface that minimizes wear and scratches, enhancing the pet's safety and reliability over time. Non-anodized pressure cooker pets are more prone to deterioration and may require more frequent replacement due to their vulnerability to rust and damage.

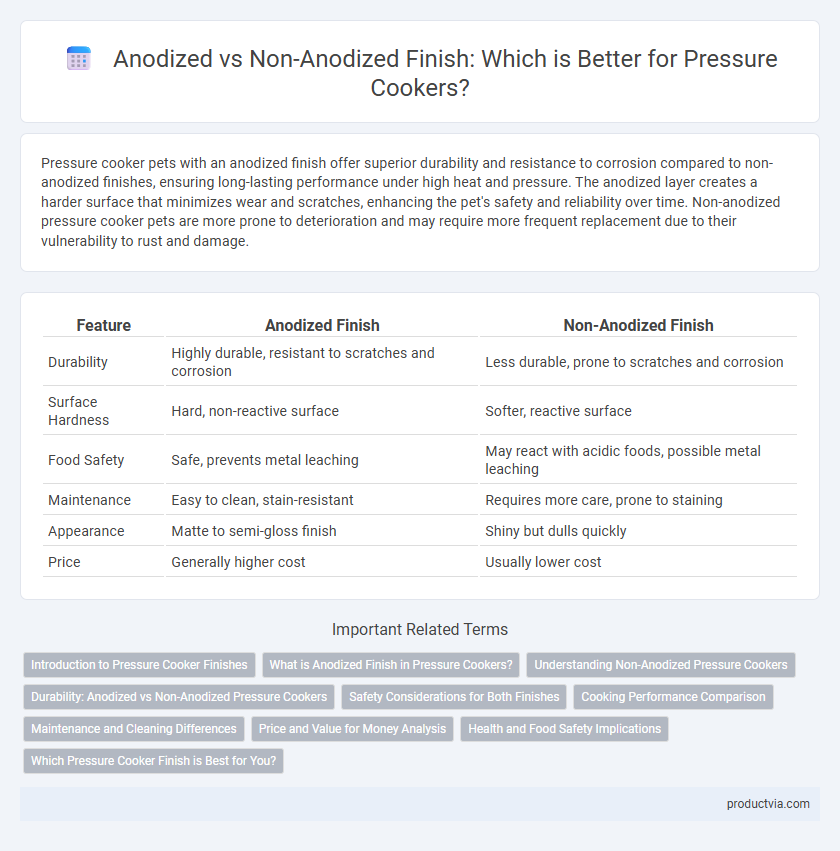

Table of Comparison

| Feature | Anodized Finish | Non-Anodized Finish |

|---|---|---|

| Durability | Highly durable, resistant to scratches and corrosion | Less durable, prone to scratches and corrosion |

| Surface Hardness | Hard, non-reactive surface | Softer, reactive surface |

| Food Safety | Safe, prevents metal leaching | May react with acidic foods, possible metal leaching |

| Maintenance | Easy to clean, stain-resistant | Requires more care, prone to staining |

| Appearance | Matte to semi-gloss finish | Shiny but dulls quickly |

| Price | Generally higher cost | Usually lower cost |

Introduction to Pressure Cooker Finishes

Anodized finish on pressure cookers enhances durability by creating a hard, non-reactive surface resistant to scratches and corrosion, making it ideal for frequent cooking. Non-anodized pressure cookers, typically made from stainless steel or aluminum, lack this protective layer, which can result in faster wear and potential reactions with acidic foods. Choosing between anodized and non-anodized finishes impacts the longevity, maintenance, and cooking performance of the pressure cooker.

What is Anodized Finish in Pressure Cookers?

Anodized finish in pressure cookers refers to a metal treatment process that enhances the durability and corrosion resistance of the cookware by creating a thick oxide layer on the aluminum surface. This finish prevents the aluminum from reacting with acidic or alkaline foods, ensuring safer cooking and preserving the taste and nutritional value of meals. Non-anodized pressure cookers lack this protective barrier, making them more prone to scratches, discoloration, and potential leaching of aluminum during cooking.

Understanding Non-Anodized Pressure Cookers

Non-anodized pressure cookers have a raw aluminum surface that is more reactive with acidic foods, which can lead to discoloration and potential metallic taste. They tend to be more affordable but require careful maintenance to prevent scratching and corrosion. Choosing non-anodized cookers means prioritizing cost savings while accepting a need for more diligent cleaning and seasoning to preserve performance.

Durability: Anodized vs Non-Anodized Pressure Cookers

Anodized pressure cookers offer superior durability and resistance to scratches, corrosion, and wear compared to non-anodized models, making them ideal for long-term use. The anodization process creates a hard, non-reactive surface that prevents metal leaching and enhances structural strength under high heat and pressure. Non-anodized pressure cookers, while often more affordable, tend to degrade faster and require more careful maintenance to avoid damage and ensure safety.

Safety Considerations for Both Finishes

Anodized finish pressure cookers offer enhanced safety due to their hardened surface, which resists scratches and corrosion, reducing the risk of metal leaching into food. Non-anodized pressure cookers, often made from raw aluminum, may pose safety concerns since aluminum can react with acidic foods, potentially affecting food quality and health. Regular inspection and proper maintenance are essential for both finishes to ensure pressure valves and seals function correctly, maintaining overall cooking safety.

Cooking Performance Comparison

Anodized finish pressure cookers offer superior heat distribution and enhanced durability due to their hard, non-porous surface, which prevents corrosion and food sticking. Non-anodized pressure cookers may have uneven heat conduction, leading to hotspots that can affect cooking consistency and increase the risk of food burning. The anodized layer also provides easier maintenance and better retention of the cooker's appearance over time, contributing to more efficient and consistent cooking performance.

Maintenance and Cleaning Differences

Anodized finish pressure cookers feature a hard, non-porous surface that resists stains, scratches, and corrosion, making them easier to clean and maintain without the risk of peeling or rusting. Non-anodized pressure cookers often require more careful handling to avoid scratching and may develop discoloration or rust over time, demanding more frequent seasoning and thorough drying after cleaning. The anodized surface simplifies maintenance by reducing residue buildup and preventing absorption of food odors, whereas non-anodized models need more rigorous cleaning to keep the cooking surface hygienic.

Price and Value for Money Analysis

Anodized finish pressure cookers offer enhanced durability and corrosion resistance at a higher price point compared to non-anodized models, which are generally more affordable but prone to scratches and wear over time. The value for money favors anodized cookware for long-term use due to its superior non-stick qualities and longer lifespan, reducing replacement costs. Non-anodized pressure cookers may suit budget-conscious buyers prioritizing initial cost savings over prolonged durability and performance.

Health and Food Safety Implications

Anodized pressure cookers feature a hard, non-reactive surface that prevents aluminum from leaching into food, reducing health risks associated with metal exposure. Non-anodized aluminum pressure cookers can react with acidic or alkaline ingredients, potentially contaminating meals and compromising food safety. Choosing anodized finishes enhances durability and ensures safer cooking, minimizing the chance of harmful substances migrating into your food.

Which Pressure Cooker Finish is Best for You?

An anodized finish on pressure cookers provides enhanced durability and resistance to scratches and corrosion, making it ideal for frequent use and long-term performance. Non-anodized finishes, often made of stainless steel or aluminum, offer a more affordable option but may be prone to wear and require careful handling to avoid damage. Choosing the best pressure cooker finish depends on your cooking habits, budget, and preference for maintenance, with anodized coatings excelling in longevity and non-anodized models suited for occasional or lighter kitchen tasks.

Anodized finish vs Non-anodized finish for pressure cooker Infographic

productvia.com

productvia.com