A single-layer base in a pressure cooker offers quick heating but often results in uneven heat distribution, which can cause food to cook inconsistently. In contrast, a sandwich base combines multiple layers of metal, typically aluminum or copper between stainless steel, ensuring better heat retention and uniform cooking performance. Choosing a sandwich base enhances durability and energy efficiency, making it ideal for prolonged cooking tasks.

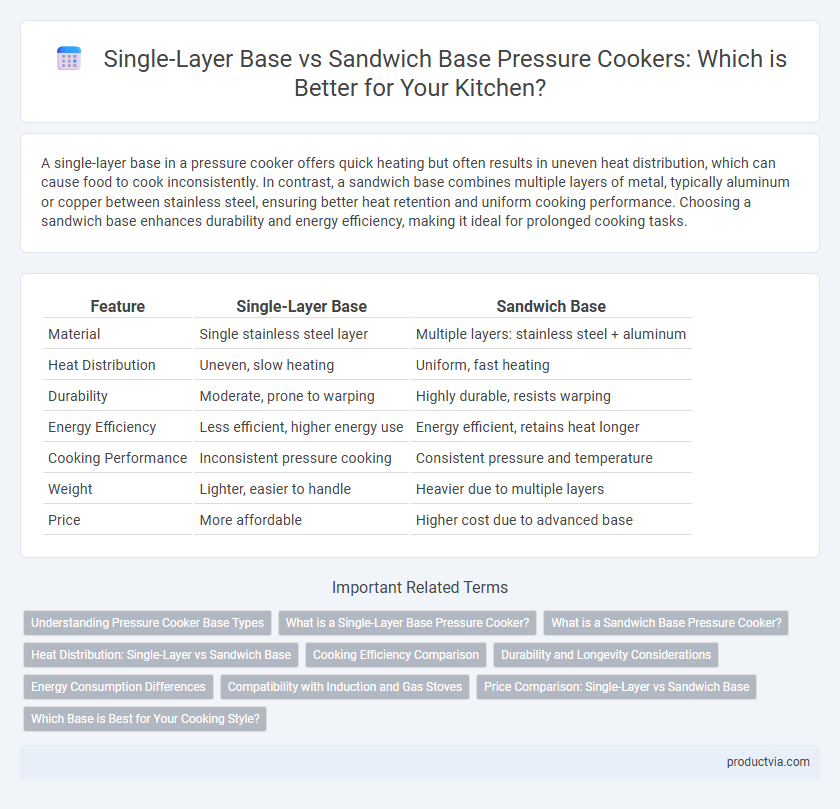

Table of Comparison

| Feature | Single-Layer Base | Sandwich Base |

|---|---|---|

| Material | Single stainless steel layer | Multiple layers: stainless steel + aluminum |

| Heat Distribution | Uneven, slow heating | Uniform, fast heating |

| Durability | Moderate, prone to warping | Highly durable, resists warping |

| Energy Efficiency | Less efficient, higher energy use | Energy efficient, retains heat longer |

| Cooking Performance | Inconsistent pressure cooking | Consistent pressure and temperature |

| Weight | Lighter, easier to handle | Heavier due to multiple layers |

| Price | More affordable | Higher cost due to advanced base |

Understanding Pressure Cooker Base Types

Single-layer bases in pressure cookers typically consist of one metal type, often aluminum, offering rapid heat conduction but less durability and uneven heat distribution compared to sandwich bases. Sandwich bases combine multiple layers of metals, such as stainless steel and aluminum, enhancing heat retention, preventing warping, and ensuring uniform cooking performance. Choosing between these base types impacts energy efficiency, cooking speed, and longevity of the pressure cooker.

What is a Single-Layer Base Pressure Cooker?

A single-layer base pressure cooker features a sole metal layer, typically stainless steel or aluminum, directly contacting the heat source, offering faster heat conduction but less heat retention compared to multi-layer bases. This design is lightweight and usually more affordable but may cause uneven heating or hot spots that can affect cooking performance. Single-layer bases are suitable for low to medium heat cooking and users who prioritize quick heating and budget-friendly options.

What is a Sandwich Base Pressure Cooker?

A sandwich base pressure cooker features a multi-layered bottom design, typically combining stainless steel with an aluminum or copper core to enhance heat distribution and retention. This construction provides uniform cooking results, preventing hotspots and improving energy efficiency compared to single-layer bases made solely from stainless steel or aluminum. Pressure cookers with a sandwich base are ideal for consistent, faster cooking performance on various stovetops.

Heat Distribution: Single-Layer vs Sandwich Base

A single-layer base in a pressure cooker typically consists of one metal, such as aluminum or stainless steel, which offers rapid heat conduction but can result in uneven heat distribution, causing hot spots that may burn food. In contrast, a sandwich base combines layers of different metals--usually an aluminum core between stainless steel layers--ensuring superior heat distribution and retention for consistent cooking performance. This multi-layer construction minimizes the risk of food sticking or burning and enhances energy efficiency during pressure cooking.

Cooking Efficiency Comparison

Single-layer bases in pressure cookers heat up quickly but often suffer from uneven heat distribution, leading to hotspots and inconsistent cooking results. Sandwich bases consist of multiple layers, typically combining aluminum and stainless steel, which enhance heat retention and promote uniform heat distribution for more efficient cooking. This multi-layer design reduces energy consumption and improves cooking performance by maintaining steady temperatures throughout the cooking process.

Durability and Longevity Considerations

A single-layer base in a pressure cooker typically offers less durability and can warp over time due to uneven heat distribution, reducing its lifespan. In contrast, a sandwich base, composed of multiple layers including an aluminum core encased in stainless steel, provides superior heat conduction and resistance to deformation, significantly enhancing longevity. Investing in a pressure cooker with a sandwich base ensures better thermal stability and a longer-lasting performance.

Energy Consumption Differences

Single-layer bases in pressure cookers typically conduct heat less efficiently, causing higher energy consumption due to uneven heat distribution and slower cooking times. Sandwich bases, composed of multiple layers combining stainless steel and aluminum, offer superior heat conduction that reduces energy usage by maintaining consistent temperatures throughout cooking. Energy efficiency improves by minimizing heat loss and shortening cooking duration when using sandwich base pressure cookers.

Compatibility with Induction and Gas Stoves

A single-layer base in pressure cookers is typically made from one type of metal, making it compatible primarily with gas stoves but often ineffective on induction cooktops due to the lack of magnetic properties. In contrast, a sandwich base combines multiple layers of metals, such as stainless steel and aluminum, ensuring excellent heat distribution and full compatibility with both induction and gas stoves. Pressure cookers featuring a sandwich base are favored for their versatility, durability, and efficient performance across diverse cooking surfaces.

Price Comparison: Single-Layer vs Sandwich Base

Single-layer base pressure cookers are generally more affordable due to simpler manufacturing processes and fewer materials used, making them ideal for budget-conscious buyers. Sandwich base pressure cookers feature multiple layers of metals like aluminum and stainless steel, offering better heat distribution and durability at a higher price point. Consumers seeking long-term performance often invest in sandwich base models despite the initial cost difference.

Which Base is Best for Your Cooking Style?

A single-layer base in pressure cookers offers quick heat conduction, ideal for fast cooking and budget-friendly options, while a sandwich base combines layers of aluminum and stainless steel to provide even heat distribution and durability, perfect for slow cooking and consistent temperature control. Choosing the best base depends on your cooking style: single-layer suits users prioritizing speed and affordability, whereas sandwich bases benefit those who need precise heat management for delicate dishes. High-quality sandwich bases reduce hotspots and improve energy efficiency, enhancing versatile cooking performance over time.

Single-layer base vs Sandwich base for pressure cooker Infographic

productvia.com

productvia.com