Non-stick coatings on sandwich makers provide easy food release and effortless cleaning, but they may wear off over time, reducing durability. Stainless steel plates offer superior longevity and resistance to scratches and corrosion, making them ideal for heavy use. Choosing stainless steel ensures a robust sandwich maker that withstands frequent cooking without compromising performance.

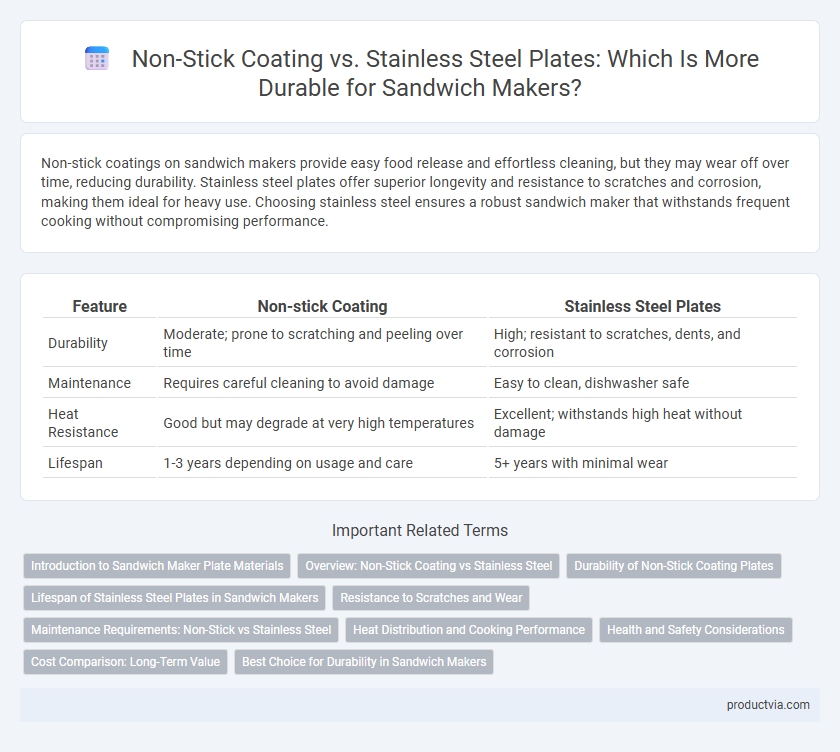

Table of Comparison

| Feature | Non-stick Coating | Stainless Steel Plates |

|---|---|---|

| Durability | Moderate; prone to scratching and peeling over time | High; resistant to scratches, dents, and corrosion |

| Maintenance | Requires careful cleaning to avoid damage | Easy to clean, dishwasher safe |

| Heat Resistance | Good but may degrade at very high temperatures | Excellent; withstands high heat without damage |

| Lifespan | 1-3 years depending on usage and care | 5+ years with minimal wear |

Introduction to Sandwich Maker Plate Materials

Non-stick coating on sandwich maker plates provides easy food release and quick cleaning but may wear off over time, reducing durability. Stainless steel plates offer superior longevity and resistance to scratches, making them ideal for heavy use and long-term durability. Choosing between non-stick and stainless steel depends on balancing ease of maintenance with the expected lifespan of sandwich maker plates.

Overview: Non-Stick Coating vs Stainless Steel

Non-stick coating in sandwich makers offers easy food release and straightforward cleaning, making it ideal for everyday use. Stainless steel plates provide superior durability and resistance to scratches, ensuring long-lasting performance even with frequent usage. Choosing between the two depends on balancing convenience and longevity in your sandwich maker's construction.

Durability of Non-Stick Coating Plates

Non-stick coating plates offer ease of cleaning and prevent food from sticking, but their durability can decline over time due to scratches and high-heat exposure. In contrast, stainless steel plates provide superior long-term durability, resisting warping and corrosion even with heavy use. Users seeking longevity often prefer stainless steel plates despite the slightly more challenging cleaning process.

Lifespan of Stainless Steel Plates in Sandwich Makers

Stainless steel plates in sandwich makers offer superior durability, maintaining their integrity and performance for several years without warping or peeling. Unlike non-stick coatings that can degrade or chip over time, stainless steel plates resist scratches and corrosion, extending the appliance's lifespan significantly. This longevity makes stainless steel a preferred choice for heavy, long-term use in sandwich makers.

Resistance to Scratches and Wear

Non-stick coated sandwich makers offer excellent resistance to scratches and wear due to their smooth, protective surface that prevents food from sticking and reduces abrasion. Stainless steel plates are more durable against physical impacts and high temperatures but can be prone to surface scratches over time without a protective coating. Choosing between non-stick coating and stainless steel plates depends on prioritizing easy cleaning and scratch resistance versus long-term durability and heat tolerance.

Maintenance Requirements: Non-Stick vs Stainless Steel

Non-stick coating on sandwich makers offers easy maintenance due to its resistance to food sticking and simple cleaning with a soft cloth or sponge, but it may wear off over time, requiring careful use and avoiding abrasive tools. Stainless steel plates, while more durable and resistant to scratches, demand regular thorough cleaning to prevent food residue buildup and potential rust spots, often requiring scrubbing and drying after each use. Choosing between non-stick and stainless steel involves balancing low maintenance with potential long-term durability concerns.

Heat Distribution and Cooking Performance

Non-stick coating on sandwich makers provides even heat distribution, preventing food from sticking and ensuring easy cleaning, but it may wear off over time affecting durability. Stainless steel plates offer superior durability and high heat retention, delivering consistent cooking performance and browning, though they require regular maintenance to avoid rust and food sticking. Choosing between these options depends on prioritizing long-term durability with stainless steel or convenient cooking with non-stick surfaces.

Health and Safety Considerations

Non-stick coating on sandwich makers offers easy cleaning and reduced oil usage, promoting healthier cooking but may degrade over time, potentially releasing harmful chemicals if scratched or overheated. Stainless steel plates provide superior durability and resist corrosion, ensuring long-term safety without chemical risks, though they may require more maintenance to prevent sticking. Selecting between non-stick and stainless steel plates depends on prioritizing ease of use versus longevity and chemical safety in sandwich maker health considerations.

Cost Comparison: Long-Term Value

Non-stick coating sandwich makers offer an affordable initial price but may require replacement sooner due to coating wear, impacting long-term value. Stainless steel plates provide superior durability and resistance to scratches, justifying a higher upfront investment with reduced maintenance and extended lifespan. Evaluating total cost of ownership favors stainless steel for users prioritizing longevity and cost efficiency over time.

Best Choice for Durability in Sandwich Makers

Non-stick coating offers easy cleaning and excellent food release but may wear off over time, reducing durability. Stainless steel plates provide superior longevity and resist scratches or peeling, making them ideal for long-term use. For the best choice in durability, stainless steel plates are recommended in sandwich makers due to their robust construction and lasting performance.

Non-stick coating vs Stainless steel plates for durability Infographic

productvia.com

productvia.com