All-metal gears in stand mixers offer superior drive durability compared to nylon gears, as they resist wear and tear under heavy use and high torque. Metal gears maintain consistent performance over time without deforming, ensuring reliable mixing even with dense doughs. Nylon gears, while quieter and less expensive, tend to wear out faster and may require more frequent replacement in demanding mixing tasks.

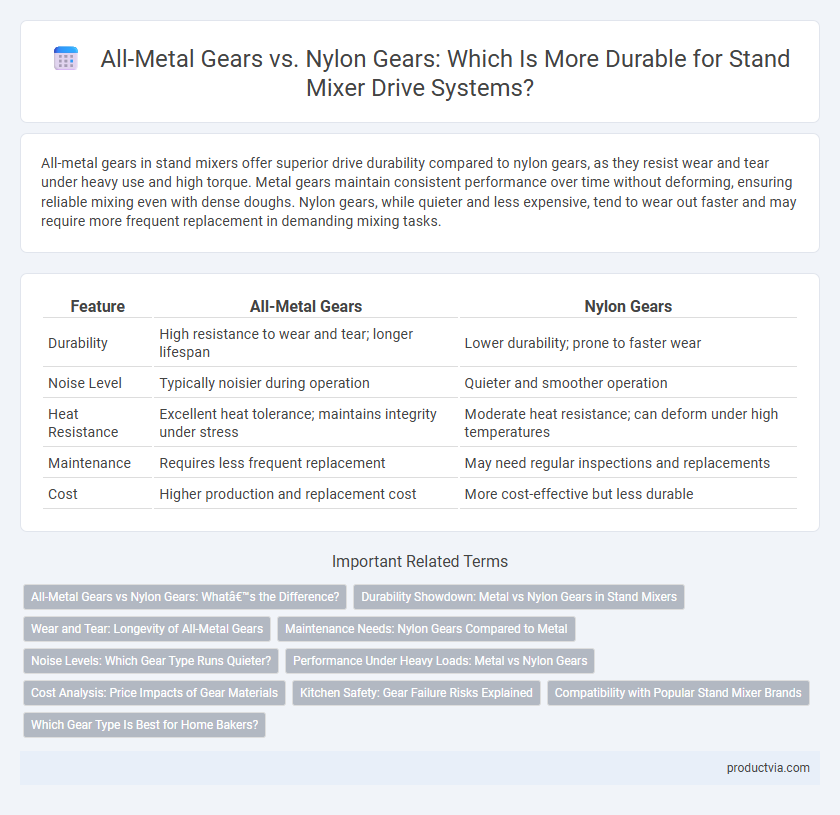

Table of Comparison

| Feature | All-Metal Gears | Nylon Gears |

|---|---|---|

| Durability | High resistance to wear and tear; longer lifespan | Lower durability; prone to faster wear |

| Noise Level | Typically noisier during operation | Quieter and smoother operation |

| Heat Resistance | Excellent heat tolerance; maintains integrity under stress | Moderate heat resistance; can deform under high temperatures |

| Maintenance | Requires less frequent replacement | May need regular inspections and replacements |

| Cost | Higher production and replacement cost | More cost-effective but less durable |

All-Metal Gears vs Nylon Gears: What’s the Difference?

All-metal gears in stand mixers offer superior durability and can withstand higher torque without wearing down, making them ideal for heavy-duty mixing tasks. Nylon gears, while quieter and less expensive, tend to degrade faster under continuous stress and are more prone to stripping or melting. Choosing all-metal gears ensures a longer lifespan and reliable performance, especially in high-powered or professional-grade mixers.

Durability Showdown: Metal vs Nylon Gears in Stand Mixers

All-metal gears in stand mixers offer superior durability and long-lasting performance, resisting wear and tear under heavy mixing loads compared to nylon gears. Nylon gears, while quieter and lighter, tend to degrade faster, especially when exposed to heat and high pressure during intense mixing tasks. For users prioritizing longevity and robust operation, all-metal gears ensure a more reliable and maintenance-free mixing experience.

Wear and Tear: Longevity of All-Metal Gears

All-metal gears in stand mixers offer superior wear resistance compared to nylon gears, significantly enhancing drive durability under heavy use. The hardened metal composition reduces deformation and abrasion, ensuring consistent performance and extended motor life over thousands of mixing cycles. Metal gears minimize the risk of gear stripping, making them ideal for high-torque tasks and long-term reliability.

Maintenance Needs: Nylon Gears Compared to Metal

Nylon gears in stand mixers require more frequent inspection and potential replacement due to their susceptibility to wear and heat damage compared to all-metal gears. While nylon gears operate quietly and absorb shock well, maintenance needs increase because they can degrade faster under heavy use or high torque conditions. In contrast, all-metal gears offer superior durability and longevity, reducing the frequency of maintenance and ensuring consistent performance over time.

Noise Levels: Which Gear Type Runs Quieter?

All-metal gears in stand mixers offer superior drive durability but tend to produce higher noise levels during operation compared to nylon gears. Nylon gears operate more quietly due to their inherent sound-dampening properties, making them preferable for noise-sensitive environments. However, the trade-off in quieter performance comes with reduced wear resistance relative to the robust metal gear counterparts.

Performance Under Heavy Loads: Metal vs Nylon Gears

All-metal gears in stand mixers offer superior performance under heavy loads due to their enhanced durability and resistance to wear, ensuring consistent torque without deformation. Nylon gears, while quieter and lighter, tend to wear down faster and may strip or fail when subjected to prolonged high-torque mixing tasks. For users frequently processing dense doughs or large batches, all-metal gears provide reliable, long-lasting drive performance that maintains mixer efficiency and lifespan.

Cost Analysis: Price Impacts of Gear Materials

All-metal gears in stand mixers generally offer superior drive durability but come with a higher initial cost due to expensive materials and manufacturing processes. Nylon gears reduce production expenses, leading to lower retail prices, but may wear out faster, increasing long-term maintenance costs. Evaluating cost efficiency requires balancing upfront investment against potential replacement frequency and repair expenses.

Kitchen Safety: Gear Failure Risks Explained

All-metal gears in stand mixers offer superior drive durability by resisting wear and heat, significantly reducing the risk of gear failure that can cause sudden motor stalls or overheating. Nylon gears, while quieter and cost-effective, are more prone to wear, cracking, and melting under heavy loads, increasing the chances of malfunction and kitchen hazards such as sparks or electrical shorts. Prioritizing metal gears enhances kitchen safety by providing reliable, long-lasting performance that minimizes breakdowns and potential injury risks during food preparation.

Compatibility with Popular Stand Mixer Brands

All-metal gears offer superior drive durability and long-term performance, making them ideal for heavy-duty tasks in popular stand mixer brands like KitchenAid and Cuisinart. Nylon gears, while quieter and often more affordable, may wear faster under intense use but remain compatible with various entry-level and mid-range stand mixers such as Hamilton Beach. Choosing gears depends on balancing durability needs with brand-specific compatibility to optimize mixer longevity.

Which Gear Type Is Best for Home Bakers?

All-metal gears provide superior durability and withstand heavy use, making them ideal for home bakers who frequently mix dense doughs or larger batches. Nylon gears, while quieter and less expensive, tend to wear out faster under consistent, high-torque conditions common in bread or pastry preparation. Home bakers prioritizing longevity and reliability should opt for all-metal gear stand mixers to ensure consistent performance and reduce maintenance needs.

All-metal gears vs nylon gears for drive durability Infographic

productvia.com

productvia.com