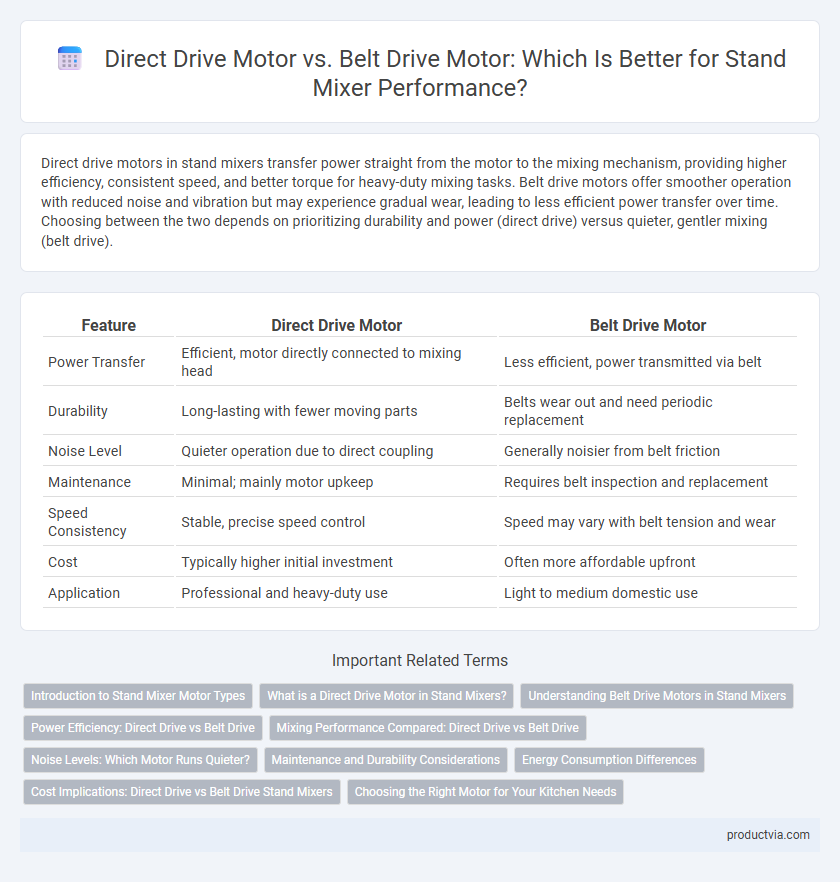

Direct drive motors in stand mixers transfer power straight from the motor to the mixing mechanism, providing higher efficiency, consistent speed, and better torque for heavy-duty mixing tasks. Belt drive motors offer smoother operation with reduced noise and vibration but may experience gradual wear, leading to less efficient power transfer over time. Choosing between the two depends on prioritizing durability and power (direct drive) versus quieter, gentler mixing (belt drive).

Table of Comparison

| Feature | Direct Drive Motor | Belt Drive Motor |

|---|---|---|

| Power Transfer | Efficient, motor directly connected to mixing head | Less efficient, power transmitted via belt |

| Durability | Long-lasting with fewer moving parts | Belts wear out and need periodic replacement |

| Noise Level | Quieter operation due to direct coupling | Generally noisier from belt friction |

| Maintenance | Minimal; mainly motor upkeep | Requires belt inspection and replacement |

| Speed Consistency | Stable, precise speed control | Speed may vary with belt tension and wear |

| Cost | Typically higher initial investment | Often more affordable upfront |

| Application | Professional and heavy-duty use | Light to medium domestic use |

Introduction to Stand Mixer Motor Types

Direct drive motors in stand mixers attach the motor shaft directly to the mixing mechanism, offering higher efficiency and reduced power loss, ideal for heavy dough and continuous use. Belt drive motors use a belt to transfer power, typically resulting in quieter operation but reduced torque and more wear over time. Understanding these motor types helps select the best mixer for tasks requiring precision, speed, and durability.

What is a Direct Drive Motor in Stand Mixers?

A direct drive motor in stand mixers connects the motor directly to the mixing mechanism, offering enhanced power efficiency and reduced mechanical loss compared to belt drive motors. This design results in quieter operation, increased durability, and consistent torque, ideal for heavy-duty mixing tasks. Stand mixers with direct drive motors typically require less maintenance and provide more precise speed control, improving overall performance.

Understanding Belt Drive Motors in Stand Mixers

Belt drive motors in stand mixers operate by using a flexible belt to connect the motor to the mixing mechanism, offering smoother and quieter performance compared to direct drive motors. This design reduces vibration and motor strain, prolonging the lifespan of the appliance while allowing for versatile speed control. However, belt drive motors may require periodic belt replacement and can deliver slightly less power efficiency than direct drive counterparts, making them ideal for home bakers prioritizing noise reduction and durability.

Power Efficiency: Direct Drive vs Belt Drive

Direct drive motors in stand mixers offer higher power efficiency by transferring energy directly from the motor to the mixing mechanism, minimizing energy loss. Belt drive motors experience some power loss due to friction and slippage between the belt and pulleys, reducing overall efficiency. As a result, direct drive systems typically provide more consistent torque and better performance during heavy mixing tasks.

Mixing Performance Compared: Direct Drive vs Belt Drive

Direct drive motors in stand mixers provide more efficient power transfer, resulting in consistent and stronger mixing performance compared to belt drive motors. Belt drive motors may experience power loss and reduced torque due to belt slippage, affecting the mixer's ability to handle heavy dough or thick batters. For tasks requiring high torque and steady speed, stand mixers with direct drive motors deliver superior and reliable mixing results.

Noise Levels: Which Motor Runs Quieter?

Direct drive motors in stand mixers operate with minimal mechanical parts, producing significantly lower noise levels compared to belt drive motors, which rely on belts that can cause additional vibration and noise during use. The direct connection between the motor and the mixing mechanism reduces rattling and humming sounds, making direct drive mixers ideal for quieter kitchen environments. Stand mixers with belt drive motors tend to emit louder, more noticeable sounds due to belt tension and wear over time.

Maintenance and Durability Considerations

Direct drive motors in stand mixers offer superior durability with fewer moving parts, reducing maintenance needs and enhancing long-term performance. Belt drive motors, while often quieter, require periodic belt replacements and more frequent maintenance, which can impact overall longevity. Choosing a direct drive motor ensures consistent power delivery and minimizes downtime due to wear and mechanical adjustments.

Energy Consumption Differences

Direct drive motors in stand mixers typically offer higher energy efficiency by transferring power directly to the mixing mechanism, reducing energy loss compared to belt drive motors. Belt drive motors experience additional friction and slippage, resulting in greater energy consumption for the same mixing tasks. Choosing a direct drive motor can lower electricity usage and improve overall performance in continuous or heavy-duty baking applications.

Cost Implications: Direct Drive vs Belt Drive Stand Mixers

Direct drive stand mixers typically offer higher efficiency and durability but come with a higher upfront cost due to advanced motor technology. Belt drive mixers are generally more affordable, making them attractive for budget-conscious buyers, but they may require more frequent maintenance and part replacements. Evaluating long-term usage costs and repair frequency is essential when choosing between direct drive and belt drive stand mixers.

Choosing the Right Motor for Your Kitchen Needs

Direct drive motors in stand mixers provide superior power transfer and durability, ensuring consistent mixing performance for heavy doughs and frequent use. Belt drive motors offer quieter operation and smoother speed changes, making them ideal for light to medium kitchen tasks. Selecting a motor depends on your baking frequency and ingredient types, with direct drive suited for professional-grade mixing and belt drive preferred for occasional home cooking.

Direct drive motor vs Belt drive motor for stand mixer performance Infographic

productvia.com

productvia.com