Overload protection in stand mixers prevents motor damage by automatically stopping the machine when excessive resistance is detected, ensuring safe operation during heavy mixing tasks. Thermal protection safeguards the motor from overheating by shutting it down if the internal temperature rises beyond safe limits, preventing long-term damage. Combining both features enhances motor durability and extends the lifespan of the stand mixer by addressing different safety risks.

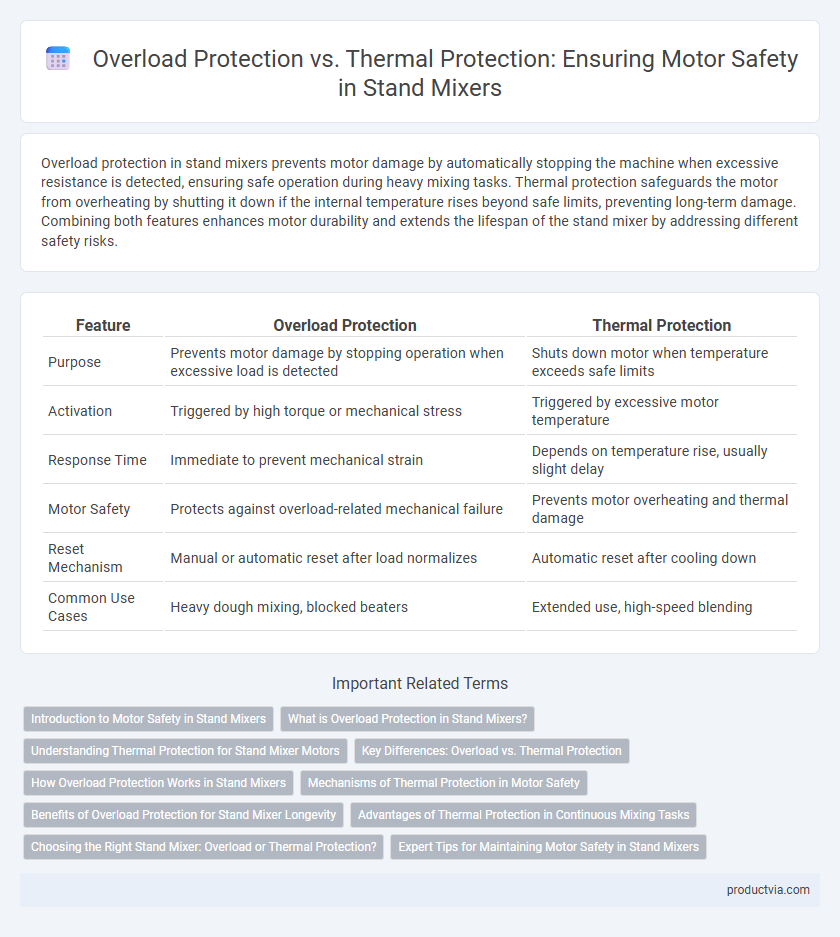

Table of Comparison

| Feature | Overload Protection | Thermal Protection |

|---|---|---|

| Purpose | Prevents motor damage by stopping operation when excessive load is detected | Shuts down motor when temperature exceeds safe limits |

| Activation | Triggered by high torque or mechanical stress | Triggered by excessive motor temperature |

| Response Time | Immediate to prevent mechanical strain | Depends on temperature rise, usually slight delay |

| Motor Safety | Protects against overload-related mechanical failure | Prevents motor overheating and thermal damage |

| Reset Mechanism | Manual or automatic reset after load normalizes | Automatic reset after cooling down |

| Common Use Cases | Heavy dough mixing, blocked beaters | Extended use, high-speed blending |

Introduction to Motor Safety in Stand Mixers

Stand mixers incorporate overload protection to prevent motor strain by automatically stopping the motor when excessive load is detected, ensuring longevity and safe operation. Thermal protection safeguards the motor from overheating by monitoring temperature levels and shutting down the mixer if critical heat thresholds are reached. Combining both overload and thermal protection enhances motor safety, reducing the risk of damage and maintaining consistent performance during heavy-duty mixing tasks.

What is Overload Protection in Stand Mixers?

Overload protection in stand mixers prevents motor damage by automatically shutting off the motor when excessive load or resistance is detected, ensuring the appliance does not overheat or burn out. This feature detects abnormal current flow caused by thick dough or heavy ingredients that could strain the motor. Overload protection enhances the longevity of stand mixers by safeguarding against mechanical stress during intensive mixing tasks.

Understanding Thermal Protection for Stand Mixer Motors

Thermal protection in stand mixer motors uses built-in thermostats or sensors to monitor temperature and automatically shut off the motor when it overheats, preventing damage from excessive heat. This system ensures the motor cools down before resuming operation, enhancing durability and safety during heavy or prolonged mixing tasks. Unlike overload protection, which responds to electrical current spikes indicating mechanical strain, thermal protection directly safeguards the motor against thermal stress caused by continuous high loads.

Key Differences: Overload vs. Thermal Protection

Overload protection in stand mixers safeguards the motor by automatically stopping it when excessive current is detected, preventing damage from heavy or stuck mixing loads. Thermal protection, on the other hand, monitors the motor's temperature and shuts it off if overheating occurs, allowing the motor to cool before resuming operation. The key difference lies in overload protection responding to electrical current surges, while thermal protection targets temperature thresholds to ensure motor longevity and safety.

How Overload Protection Works in Stand Mixers

Overload protection in stand mixers functions by automatically detecting excessive strain on the motor, pausing operation to prevent damage from overheating or mechanical stress. This system uses sensors to monitor current flow and motor load, shutting off power when thresholds are exceeded to safeguard internal components. Effective overload protection extends motor lifespan and ensures mixer reliability during heavy-duty mixing tasks.

Mechanisms of Thermal Protection in Motor Safety

Thermal protection mechanisms in stand mixer motors utilize temperature sensors and automatic shutoff systems to prevent overheating by interrupting power when critical heat thresholds are reached. These sensors continuously monitor the motor's heat levels, enabling the device to cool down before damage occurs, preserving the motor's longevity. Overload protection differs by responding to excessive current draw or mechanical resistance, but thermal protection specifically targets heat buildup, offering precise motor safety through real-time temperature feedback.

Benefits of Overload Protection for Stand Mixer Longevity

Overload protection in stand mixers prevents motor damage by automatically shutting off the motor when excessive current is detected, reducing wear and tear during heavy mixing tasks. This feature extends the appliance's lifespan by avoiding overheating and mechanical stress that can degrade internal components. Compared to thermal protection, overload protection offers more immediate response to motor strain, ensuring consistent performance and durability over time.

Advantages of Thermal Protection in Continuous Mixing Tasks

Thermal protection in stand mixers offers superior motor safety during continuous mixing tasks by automatically shutting off the motor when it reaches a critical temperature, preventing overheating and potential damage. This feature extends the motor's lifespan and ensures consistent performance without interruptions caused by overload errors. Unlike overload protection, thermal protection allows the mixer to handle extended workloads more efficiently, making it ideal for heavy-duty or prolonged mixing operations.

Choosing the Right Stand Mixer: Overload or Thermal Protection?

Choosing the right stand mixer involves understanding the difference between overload protection and thermal protection for motor safety. Overload protection prevents motor damage by automatically stopping the mixer if it detects excessive force or resistance, ideal for heavy dough or thick mixtures. Thermal protection, on the other hand, safeguards the motor from overheating by shutting it down when temperatures reach unsafe levels, ensuring long-term durability during extended use.

Expert Tips for Maintaining Motor Safety in Stand Mixers

Overload protection in stand mixers prevents motor damage by automatically shutting off the motor when excessive resistance is detected, ensuring safe operation during heavy mixing tasks. Thermal protection activates when the motor reaches a critical temperature, temporarily stopping the mixer to cool down and avoid overheating issues. Experts recommend regularly cleaning ventilation slots and avoiding prolonged continuous use to optimize both overload and thermal protection systems for long-lasting motor performance.

Overload protection vs Thermal protection for motor safety in stand mixers Infographic

productvia.com

productvia.com