Automatic oil filtration in deep fryer pets ensures continuous cleanliness by filtering out food particles and contaminants without interrupting cooking cycles, enhancing oil longevity and flavor consistency. Manual draining requires physically removing the oil for filtration or replacement, which is time-consuming and can lead to oil degradation if not done promptly. Choosing automatic filtration reduces maintenance effort and promotes healthier cooking by maintaining oil quality more effectively than manual methods.

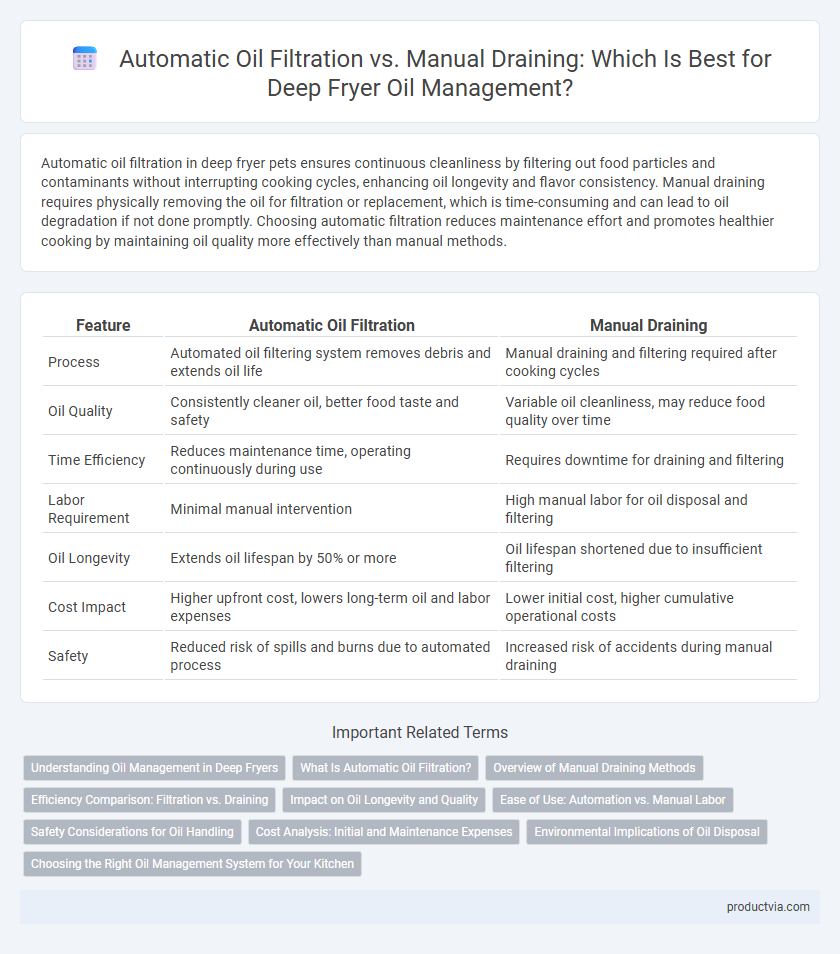

Table of Comparison

| Feature | Automatic Oil Filtration | Manual Draining |

|---|---|---|

| Process | Automated oil filtering system removes debris and extends oil life | Manual draining and filtering required after cooking cycles |

| Oil Quality | Consistently cleaner oil, better food taste and safety | Variable oil cleanliness, may reduce food quality over time |

| Time Efficiency | Reduces maintenance time, operating continuously during use | Requires downtime for draining and filtering |

| Labor Requirement | Minimal manual intervention | High manual labor for oil disposal and filtering |

| Oil Longevity | Extends oil lifespan by 50% or more | Oil lifespan shortened due to insufficient filtering |

| Cost Impact | Higher upfront cost, lowers long-term oil and labor expenses | Lower initial cost, higher cumulative operational costs |

| Safety | Reduced risk of spills and burns due to automated process | Increased risk of accidents during manual draining |

Understanding Oil Management in Deep Fryers

Automatic oil filtration systems in deep fryers enhance oil longevity by continuously removing food particles and impurities, reducing the need for frequent oil changes. Manual draining requires operators to physically remove and filter the oil, increasing downtime and the risk of inconsistent filtering. Proper oil management through filtration improves food quality, reduces operating costs, and extends the fryer's lifespan.

What Is Automatic Oil Filtration?

Automatic oil filtration is a technology integrated into deep fryers that continuously removes food particles and impurities from frying oil during cooking, extending oil life and maintaining quality. This system uses a built-in pump and filter mechanism to recirculate and clean the oil without interrupting the frying process, reducing labor and waste. Compared to manual draining, automatic filtration improves efficiency, reduces production downtime, and ensures a consistent frying environment.

Overview of Manual Draining Methods

Manual draining methods for oil management in deep fryers typically involve physically removing used oil through valves or drains, requiring more frequent human intervention. This approach demands careful handling to prevent spills and ensure proper disposal or recycling of oil. While cost-effective upfront, manual draining increases labor time and the risk of inconsistent oil quality compared to automatic filtration systems.

Efficiency Comparison: Filtration vs. Draining

Automatic oil filtration systems significantly improve efficiency by continuously removing food particles and impurities, extending oil life and reducing downtime for deep fryers. Manual draining requires full oil replacement or extended rest periods, causing longer fryer downtime and inconsistent oil quality. Continuous filtration optimizes frying performance and lowers operational costs compared to periodic manual draining processes.

Impact on Oil Longevity and Quality

Automatic oil filtration systems in deep fryers consistently remove food particles and impurities, significantly extending oil longevity and maintaining optimal oil quality. Manual draining relies on periodic oil removal and can lead to inconsistent filtration, resulting in faster oil degradation and fluctuating frying results. Investing in automatic filtration enhances oil stability, reduces oxidation, and improves overall food taste compared to manual methods.

Ease of Use: Automation vs. Manual Labor

Automatic oil filtration systems in deep fryers significantly reduce manual labor by continuously filtering oil during operation, ensuring consistent oil quality and minimizing downtime. Manual draining requires physically removing and disposing of oil, which is time-consuming and increases the risk of spills and burns. Automation streamlines oil management processes, enhancing kitchen efficiency and safety compared to manual draining methods.

Safety Considerations for Oil Handling

Automatic oil filtration systems significantly reduce the risk of burns and spills by minimizing direct contact with hot oil, enhancing overall kitchen safety. Manual draining requires careful handling and precise timing to avoid accidents, increasing the likelihood of exposure to hot oil and potential injuries. Integrating automatic oil filtration improves safe oil management by limiting human error and maintaining oil quality more consistently.

Cost Analysis: Initial and Maintenance Expenses

Automatic oil filtration systems typically involve higher initial costs due to advanced technology and installation requirements but reduce long-term expenses by minimizing oil waste and extending oil life. Manual draining setups have lower upfront investment but incur higher ongoing maintenance costs and frequent oil replacements, increasing total operating expenses. Evaluating the balance between upfront capital and recurring costs is crucial for optimizing overall cost-effectiveness in deep fryer oil management.

Environmental Implications of Oil Disposal

Automatic oil filtration systems reduce the frequency of oil changes by continuously removing food particles and contaminants, minimizing oil waste and lowering environmental impact. Manual draining often leads to improper disposal practices, increasing the risk of oil entering waterways and causing pollution. Efficient oil management through automatic filtration supports sustainable practices by extending oil usability and reducing hazardous waste generation.

Choosing the Right Oil Management System for Your Kitchen

Automatic oil filtration systems enhance oil longevity by continuously filtering out food particles, improving fryer efficiency and reducing labor costs. Manual draining requires more frequent oil changes and labor-intensive maintenance, which can increase downtime and costs. Selecting an automatic oil filtration system ensures consistent oil quality and optimal kitchen productivity, especially in high-volume commercial environments.

Automatic oil filtration vs Manual draining for oil management Infographic

productvia.com

productvia.com