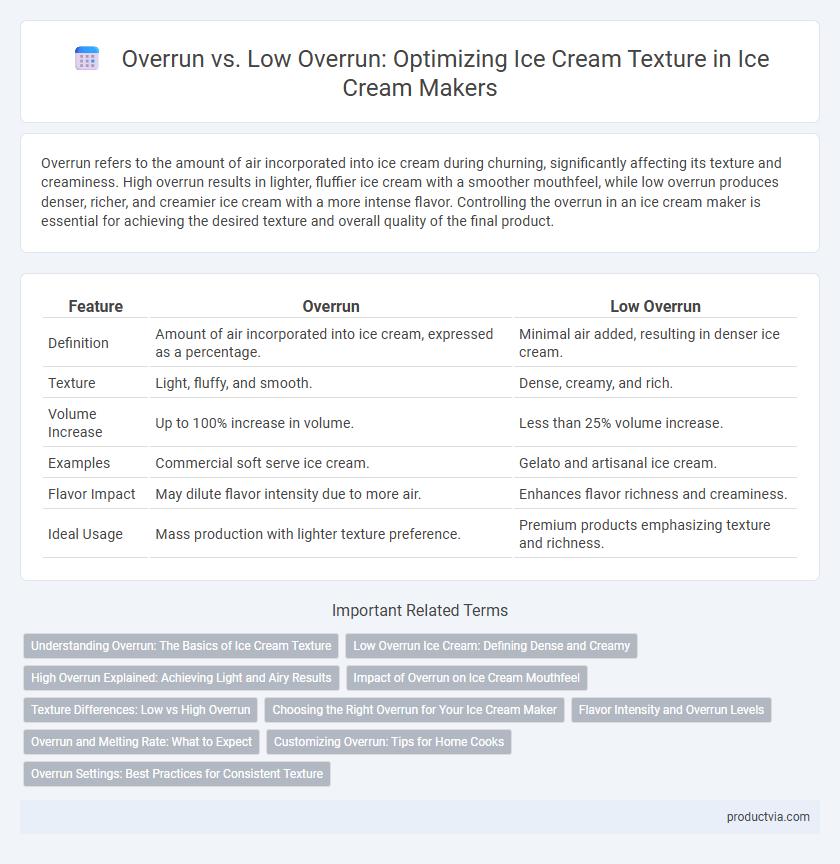

Overrun refers to the amount of air incorporated into ice cream during churning, significantly affecting its texture and creaminess. High overrun results in lighter, fluffier ice cream with a smoother mouthfeel, while low overrun produces denser, richer, and creamier ice cream with a more intense flavor. Controlling the overrun in an ice cream maker is essential for achieving the desired texture and overall quality of the final product.

Table of Comparison

| Feature | Overrun | Low Overrun |

|---|---|---|

| Definition | Amount of air incorporated into ice cream, expressed as a percentage. | Minimal air added, resulting in denser ice cream. |

| Texture | Light, fluffy, and smooth. | Dense, creamy, and rich. |

| Volume Increase | Up to 100% increase in volume. | Less than 25% volume increase. |

| Examples | Commercial soft serve ice cream. | Gelato and artisanal ice cream. |

| Flavor Impact | May dilute flavor intensity due to more air. | Enhances flavor richness and creaminess. |

| Ideal Usage | Mass production with lighter texture preference. | Premium products emphasizing texture and richness. |

Understanding Overrun: The Basics of Ice Cream Texture

Overrun in ice cream making refers to the amount of air incorporated into the mix, significantly impacting texture and mouthfeel. High overrun results in lighter, fluffier ice cream, commonly seen in commercial products, while low overrun produces denser, creamier textures favored in artisanal varieties. Controlling overrun allows precise manipulation of ice crystal formation and smoothness, essential for achieving desired richness and structural integrity in frozen desserts.

Low Overrun Ice Cream: Defining Dense and Creamy

Low overrun ice cream contains less air, resulting in a denser, creamier texture compared to high overrun varieties. This reduced air incorporation enhances flavor intensity and provides a richer mouthfeel, making it a preferred choice for premium, artisanal ice creams. Control over overrun levels allows ice cream makers to tailor texture and consistency to specific quality standards and consumer preferences.

High Overrun Explained: Achieving Light and Airy Results

High overrun in ice cream making refers to the incorporation of a significant amount of air, often ranging from 50% to 100%, which results in a light and airy texture. Achieving high overrun involves using specialized ice cream makers that efficiently whip air into the mixture during freezing, enhancing creaminess without increasing fat content. This balance between air and ice cream base is crucial for producing a smooth, fluffy product preferred in many commercial and artisanal ice creams.

Impact of Overrun on Ice Cream Mouthfeel

Overrun directly influences ice cream texture by controlling the amount of air incorporated during freezing, with higher overrun yielding lighter, fluffier ice cream and lower overrun producing denser, creamier mouthfeel. Low overrun enhances richness and smoothness, making the ice cream feel more indulgent and velvety on the palate. Understanding overrun percentages, typically ranging from 20% in premium gelatos to over 100% in commercial varieties, is critical for tailoring texture in ice cream production.

Texture Differences: Low vs High Overrun

High overrun in ice cream making incorporates more air, resulting in a lighter, fluffier texture with increased volume, while low overrun produces a denser, creamier consistency due to less air content. Low overrun ice cream offers a richer mouthfeel and more intense flavor because of its compact structure, whereas high overrun varieties can feel airy and less rich. Controlling overrun precisely is essential for achieving the desired texture and overall quality in artisanal and commercial ice cream products.

Choosing the Right Overrun for Your Ice Cream Maker

Selecting the right overrun percentage is essential for achieving the desired texture in your ice cream maker, with high overrun creating a lighter, airier product and low overrun yielding a denser, creamier texture. Overrun levels typically range from 20% to 100%, where commercial ice cream often targets 70-100%, while gelato and artisanal varieties prefer 20-50% to preserve richness and flavor intensity. Understanding your machine's capabilities and the type of ice cream you want allows precise control over overrun, optimizing texture and mouthfeel.

Flavor Intensity and Overrun Levels

Low overrun in ice cream makers results in denser texture and more intense flavor because less air is incorporated during freezing, preserving richer taste compounds. High overrun increases volume by adding air, creating a lighter texture but diluting flavor intensity, which can make the ice cream taste less rich. Controlling overrun levels allows precise balance between creaminess, texture, and flavor strength for customized ice cream quality.

Overrun and Melting Rate: What to Expect

Overrun in ice cream makers refers to the amount of air incorporated into the mixture during freezing, directly influencing texture and volume. Higher overrun results in a lighter, creamier texture with a slower melting rate, while low overrun produces denser ice cream that melts faster due to less air content. Understanding overrun balance is crucial for controlling ice cream consistency and optimizing melting behavior for desired mouthfeel.

Customizing Overrun: Tips for Home Cooks

Customizing overrun in an ice cream maker allows home cooks to control the texture and creaminess of their frozen desserts by adjusting the amount of air incorporated during churning. Lower overrun results in denser, richer ice cream with a firmer texture, while higher overrun produces lighter, fluffier ice cream with increased volume. Experimenting with overrun settings and churn speed helps achieve desired texture profiles tailored to personal taste preferences and recipe requirements.

Overrun Settings: Best Practices for Consistent Texture

Overrun settings significantly influence the texture and creaminess of ice cream, with higher overrun producing a lighter, airier product while low overrun yields denser, richer textures. Maintaining consistent overrun through precise control of air incorporation and freezing speed ensures predictable ice crystal formation, crucial for smoothness. Best practices involve calibrating the machine's air intake and monitoring batch size to achieve targeted overrun percentages, typically between 20% and 100%, depending on the desired texture profile.

Overrun vs Low Overrun for Texture Control Infographic

productvia.com

productvia.com