Gel canister ice cream makers rely on freezing the canister in a freezer before use, providing a simple and affordable option with limited batch capacity and longer preparation time. Built-in refrigeration models feature an integrated compressor that continuously freezes the mixture during churning, offering consistent results, faster production, and the ability to make multiple batches without pre-freezing. Choosing between the two depends on convenience, budget, and how frequently you plan to make ice cream with your pet-friendly machine.

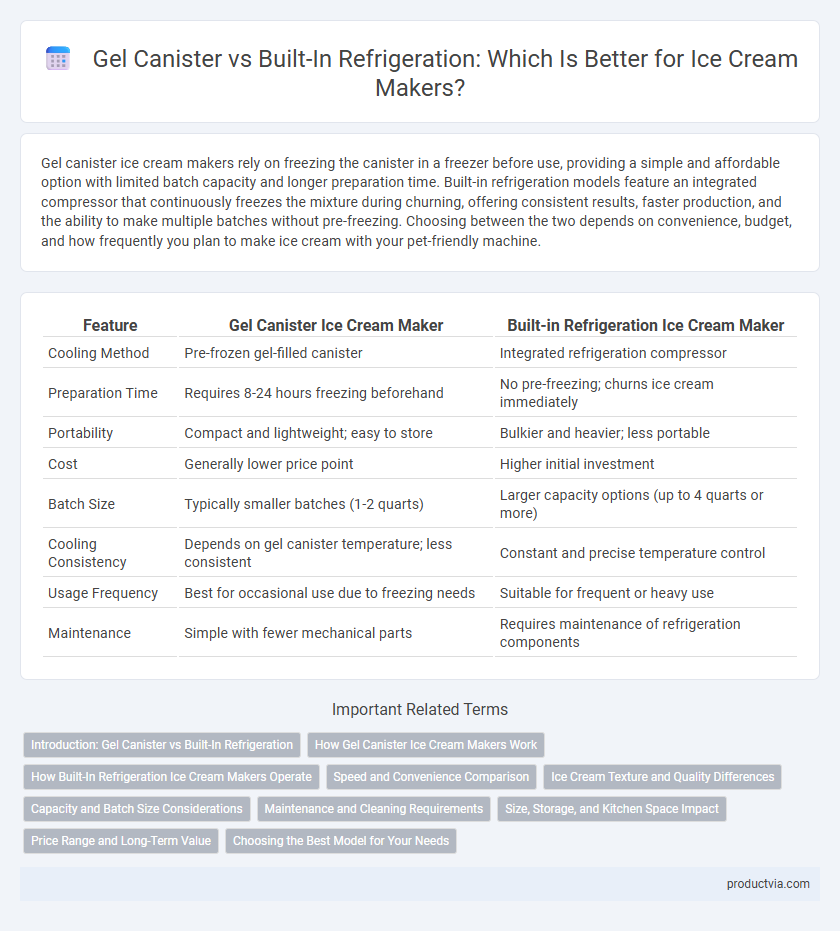

Table of Comparison

| Feature | Gel Canister Ice Cream Maker | Built-in Refrigeration Ice Cream Maker |

|---|---|---|

| Cooling Method | Pre-frozen gel-filled canister | Integrated refrigeration compressor |

| Preparation Time | Requires 8-24 hours freezing beforehand | No pre-freezing; churns ice cream immediately |

| Portability | Compact and lightweight; easy to store | Bulkier and heavier; less portable |

| Cost | Generally lower price point | Higher initial investment |

| Batch Size | Typically smaller batches (1-2 quarts) | Larger capacity options (up to 4 quarts or more) |

| Cooling Consistency | Depends on gel canister temperature; less consistent | Constant and precise temperature control |

| Usage Frequency | Best for occasional use due to freezing needs | Suitable for frequent or heavy use |

| Maintenance | Simple with fewer mechanical parts | Requires maintenance of refrigeration components |

Introduction: Gel Canister vs Built-In Refrigeration

Gel canister ice cream makers use a pre-frozen container filled with gel to chill the mixture, offering portability and ease of use without the need for electricity. Built-in refrigeration systems provide continuous cooling through an integrated compressor, allowing for multiple batches without waiting for a gel canister to refreeze. Choosing between the two depends on preferences for convenience, batch frequency, and appliance size.

How Gel Canister Ice Cream Makers Work

Gel canister ice cream makers operate by pre-freezing a removable cylinder filled with a gel coolant, which absorbs heat as the mixture churns, effectively freezing the ice cream base. The gel maintains a consistently low temperature, eliminating the need for bulky external freezers or electricity during the churning process. This system offers portability and simplicity, making gel canister models ideal for home use and small batches.

How Built-In Refrigeration Ice Cream Makers Operate

Built-in refrigeration ice cream makers use a self-contained compressor system to continuously chill the mixing bowl, eliminating the need for pre-freezing gel canisters. This technology maintains a consistent low temperature throughout the freezing process, resulting in smoother and creamier ice cream textures. The integrated compressor also allows for multiple batches without downtime, enhancing convenience and efficiency.

Speed and Convenience Comparison

Gel canister ice cream makers require pre-freezing the canister for at least 12 hours, which delays preparation but offer a lightweight, portable option. Built-in refrigeration models eliminate waiting time by freezing the mixture directly inside the machine, allowing for faster production, typically within 20 to 40 minutes. While built-in refrigeration provides greater convenience and continuous use, gel canisters offer simplicity without the need for a power source.

Ice Cream Texture and Quality Differences

Gel canister ice cream makers provide consistent freezing temperatures but may struggle to maintain uniform cold contact, resulting in slightly icier textures. Built-in refrigeration systems offer precise temperature control and continuous cooling, producing smoother, creamier ice cream with optimal overrun and reduced ice crystal formation. The difference in freezing mechanisms directly impacts the final product's texture quality, with built-in refrigeration generally yielding superior creaminess and mouthfeel.

Capacity and Batch Size Considerations

Gel canister ice cream makers typically have smaller capacities, ranging from 1 to 2 quarts, making them suitable for small batches and occasional use. Built-in refrigeration models often offer larger capacities, sometimes exceeding 4 quarts, allowing for multiple batches without re-freezing. Users prioritizing frequent use and larger batch sizes benefit from the consistent performance and greater capacity of built-in refrigeration systems.

Maintenance and Cleaning Requirements

Gel canister-based ice cream makers require regular freezing of the canister before each use, followed by thorough cleaning to prevent residue buildup and maintain hygiene. Built-in refrigeration models eliminate the pre-freezing step but demand periodic cleaning of internal components and condenser coils to ensure optimal cooling performance. Both types benefit from disassembling removable parts for deep cleaning to extend the machine's lifespan and preserve ice cream quality.

Size, Storage, and Kitchen Space Impact

Gel canister ice cream makers are typically compact and lightweight, making them easy to store in small kitchen cabinets or refrigerators, ideal for limited kitchen spaces. Built-in refrigeration units require more counter space and often a dedicated storage area due to their larger size and integrated cooling system. Choosing between the two affects kitchen organization: gel canisters offer portability and convenient storage, while built-in models demand permanent placement but provide continuous operation without pre-freezing requirements.

Price Range and Long-Term Value

Gel canister ice cream makers typically have a lower initial price range, making them an affordable option for casual use. Built-in refrigeration models come with a higher upfront cost but offer consistent performance without the need for pre-freezing, enhancing long-term convenience and savings. Investing in a built-in refrigeration unit often results in better durability and efficiency, providing greater long-term value compared to gel canisters.

Choosing the Best Model for Your Needs

Gel canister ice cream makers require pre-freezing the canister for several hours, making them ideal for occasional use and easy storage. Built-in refrigeration models offer continuous use without freezing delays, suitable for frequent ice cream making and consistent temperature control. Choosing the best model depends on your usage frequency, available space, and desired convenience for homemade ice cream production.

Gel canister vs Built-in refrigeration for ice cream maker Infographic

productvia.com

productvia.com