Continuous output ice cream makers offer the advantage of producing ice cream without interruption, ensuring a consistent flow ideal for serving multiple pets quickly. Batch output machines require pausing to prepare new mixtures after each cycle, which can delay serving times but allow for customization of flavors in separate batches. Choosing between the two depends on whether speed or variety is the priority when treating your pet.

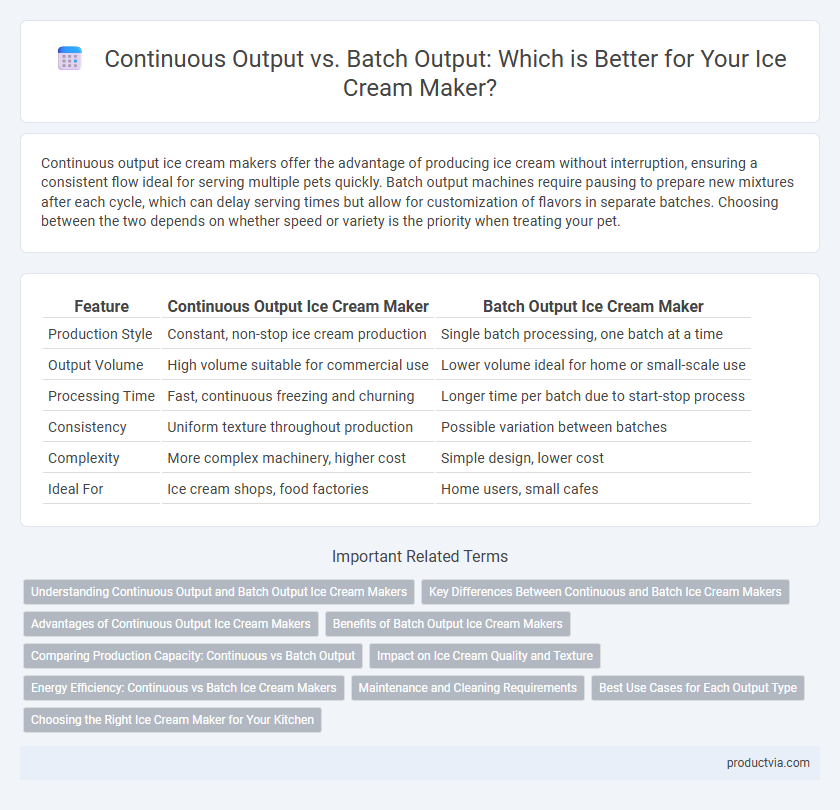

Table of Comparison

| Feature | Continuous Output Ice Cream Maker | Batch Output Ice Cream Maker |

|---|---|---|

| Production Style | Constant, non-stop ice cream production | Single batch processing, one batch at a time |

| Output Volume | High volume suitable for commercial use | Lower volume ideal for home or small-scale use |

| Processing Time | Fast, continuous freezing and churning | Longer time per batch due to start-stop process |

| Consistency | Uniform texture throughout production | Possible variation between batches |

| Complexity | More complex machinery, higher cost | Simple design, lower cost |

| Ideal For | Ice cream shops, food factories | Home users, small cafes |

Understanding Continuous Output and Batch Output Ice Cream Makers

Continuous output ice cream makers produce ice cream non-stop by continuously freezing and dispensing, ideal for high-volume production in commercial settings. Batch output ice cream makers freeze mixture in separate portions, allowing control over texture and flavor in each batch, preferred for home use or artisanal applications. Understanding these differences helps select the right machine based on production needs, consistency, and operational efficiency.

Key Differences Between Continuous and Batch Ice Cream Makers

Continuous ice cream makers produce a steady flow of ice cream by continuously freezing and dispensing the mixture, ideal for high-volume output and commercial use. Batch ice cream makers prepare fixed quantities in each cycle, allowing greater control over texture and ingredient customization, making them popular for home use. The key differences lie in production volume, processing time, and customization flexibility.

Advantages of Continuous Output Ice Cream Makers

Continuous output ice cream makers provide a steady stream of frozen dessert without interruption, enhancing efficiency for high-demand environments such as ice cream parlors and restaurants. They minimize wait times and maintain consistent texture and temperature by continuously freezing and dispensing ice cream. This method reduces labor and increases productivity compared to batch output machines, which require breaks for refreezing between servings.

Benefits of Batch Output Ice Cream Makers

Batch output ice cream makers provide precise control over ingredient mixing and freezing time, resulting in consistently creamy and customizable flavors. These machines allow users to produce smaller quantities, minimizing waste and enabling experimentation with new recipes. Their simple design also requires less maintenance compared to continuous output models, making them ideal for home use and small-scale operations.

Comparing Production Capacity: Continuous vs Batch Output

Continuous output ice cream makers provide a higher production capacity by allowing nonstop ice cream churning, ideal for commercial use and large-scale demand. Batch output machines produce fixed quantities per cycle, better suited for home or small-batch production with more control over flavor and texture variations. The continuous model maximizes efficiency and volume, while batch output prioritizes customization and precision in each batch.

Impact on Ice Cream Quality and Texture

Continuous output ice cream makers maintain a consistent churning process that promotes uniform air incorporation, resulting in smoother texture and creamier ice cream compared to batch output models. Batch output machines often produce ice cream in discrete portions, which can lead to slight temperature fluctuations and variable air content, potentially causing denser or icier textures. The continuous freezing mechanism in continuous output machines enhances ice crystal control, improving overall ice cream quality and mouthfeel.

Energy Efficiency: Continuous vs Batch Ice Cream Makers

Continuous output ice cream makers typically consume less energy per serving by maintaining a steady production process without frequent reheating or cooldown cycles. Batch output machines require repeated startup phases that increase energy consumption due to reheating and freezing intervals. Energy-efficient models optimize motor and compressor use, with continuous machines often outperforming batch types in reducing overall electricity usage.

Maintenance and Cleaning Requirements

Continuous output ice cream makers typically feature self-cleaning or easy-disassemble components that reduce maintenance time and simplify cleaning processes. Batch output machines often require manual dismantling and thorough cleaning after each use, increasing downtime and labor intensity. Selecting a machine with dishwasher-safe parts and straightforward maintenance protocols can significantly improve hygiene standards and operational efficiency.

Best Use Cases for Each Output Type

Continuous output ice cream makers excel in commercial settings where large volumes of ice cream are needed rapidly, such as in ice cream shops and food service industries. Batch output machines are ideal for home use or small-scale production, offering control over ingredient customization and portion size with each batch. Selecting the right output type depends on production volume requirements and desired flexibility in flavor experimentation.

Choosing the Right Ice Cream Maker for Your Kitchen

Continuous output ice cream makers provide a steady flow of freshly churned ice cream, ideal for large families or frequent entertaining. Batch output machines produce set quantities per cycle, offering control over portion sizes and flavors, perfect for home use and recipe experimentation. Selecting the right ice cream maker depends on your typical serving needs, kitchen space, and desire for speed versus customization.

Continuous Output vs Batch Output for Ice Cream Maker Infographic

productvia.com

productvia.com