Vertical scrape mechanisms in ice cream maker pets ensure thorough ingredient blending by pushing mixtures from the sides towards the center, resulting in a smooth texture. Horizontal scrape designs gently fold ingredients over as the paddle rotates, promoting even freezing and preventing ice crystals. Choosing between vertical and horizontal scrape systems directly impacts the creaminess and consistency of homemade ice cream.

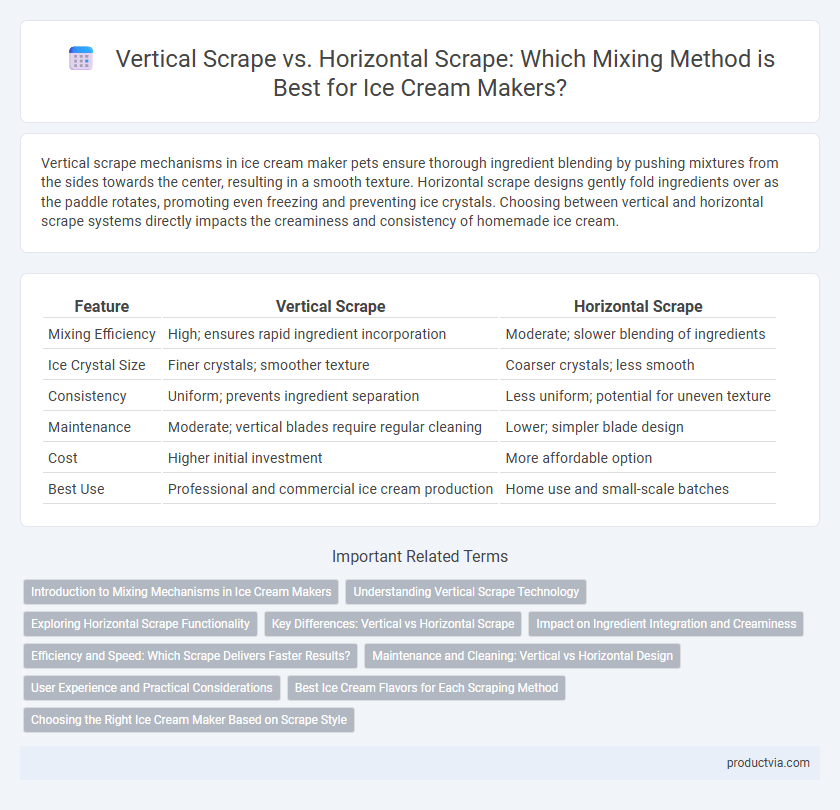

Table of Comparison

| Feature | Vertical Scrape | Horizontal Scrape |

|---|---|---|

| Mixing Efficiency | High; ensures rapid ingredient incorporation | Moderate; slower blending of ingredients |

| Ice Crystal Size | Finer crystals; smoother texture | Coarser crystals; less smooth |

| Consistency | Uniform; prevents ingredient separation | Less uniform; potential for uneven texture |

| Maintenance | Moderate; vertical blades require regular cleaning | Lower; simpler blade design |

| Cost | Higher initial investment | More affordable option |

| Best Use | Professional and commercial ice cream production | Home use and small-scale batches |

Introduction to Mixing Mechanisms in Ice Cream Makers

Vertical scrape systems in ice cream makers use blades mounted on a vertical axis to continuously scrape and mix ingredients, promoting uniform freezing and reducing ice crystal formation. Horizontal scrape mechanisms employ horizontal rotating blades that mix and aerate the ice cream base while preventing ingredient buildup along the sides of the freezing chamber. Both methods optimize texture and consistency by ensuring even ingredient distribution and efficient heat transfer during the freezing process.

Understanding Vertical Scrape Technology

Vertical scrape technology in ice cream makers involves a rotating blade that continuously scrapes the mixture off the cylinder's vertical walls, ensuring uniform freezing and consistent texture. This method enhances ingredient integration by preventing ice crystal formation and promoting thorough mixing of air and flavors. Compared to horizontal scrape systems, vertical scrape designs offer improved efficiency in maintaining smoothness and reducing freezing time.

Exploring Horizontal Scrape Functionality

The horizontal scrape mechanism in ice cream makers enhances ingredient mixing by continuously scraping the sides and bottom of the freezing chamber, ensuring even distribution and preventing ice crystal formation. This functionality promotes a smoother, creamier texture by maintaining consistent temperature and ingredient integration throughout the freezing process. Unlike vertical scrape systems, horizontal scrapers provide more thorough mixing by covering a larger surface area simultaneously.

Key Differences: Vertical vs Horizontal Scrape

Vertical scrape ice cream makers use a rotating paddle that moves ingredients upward along the sides of the freezing cylinder, ensuring consistent scraping and incorporation of air for smooth texture. Horizontal scrape machines feature a rotating dasher that mixes ingredients horizontally, often providing faster mixing but with potential for uneven scraping compared to vertical designs. Key differences include the direction of ingredient movement, texture consistency, and scraping efficiency, influencing the final ice cream quality and manufacturing speed.

Impact on Ingredient Integration and Creaminess

Vertical scrape ice cream makers enhance ingredient integration by continuously scraping the mixture from the sides and bottom, preventing ice crystal formation and promoting uniform texture. Horizontal scrape machines evenly mix ingredients by rotating scrapers horizontally, ensuring consistent creaminess throughout the batch. The choice between vertical and horizontal scrape designs significantly affects the final product's smoothness and flavor distribution.

Efficiency and Speed: Which Scrape Delivers Faster Results?

Horizontal scrape ice cream makers typically offer faster mixing speeds due to continuous and uniform ingredient contact along the freezing surface, promoting quicker freezing and smoother texture. Vertical scrape machines may provide efficient mixing but often require more time for the paddle to cover all ingredients thoroughly. For rapid processing and optimized efficiency, horizontal scrape designs generally deliver faster results in ice cream production.

Maintenance and Cleaning: Vertical vs Horizontal Design

Vertical scrape ice cream makers feature blades that move up and down, offering easier access for thorough cleaning and reducing residue buildup in corners, which simplifies maintenance. Horizontal scrape machines often have blades rotating horizontally around the cylinder, making some areas harder to reach and clean, potentially requiring more disassembly and time-consuming upkeep. The vertical design minimizes downtime by enabling quicker, more efficient maintenance, while horizontal scrape models may demand more frequent deep cleaning to maintain hygiene and performance.

User Experience and Practical Considerations

Vertical scrape ice cream makers provide more consistent ingredient distribution by scraping the freezer bowl from top to bottom, enhancing texture uniformity and minimizing ice crystal formation. Horizontal scrape models typically offer faster mixing cycles and easier bowl removal, improving user convenience but may result in less even ingredient integration. Practical user considerations include workspace size and cleaning preferences, where vertical scrape units often require more vertical space while horizontal scrape designs favor compact kitchens.

Best Ice Cream Flavors for Each Scraping Method

Vertical scrape ice cream makers excel at blending fruit-based and chunky flavors like strawberry and chocolate chip, ensuring even distribution without over-processing. Horizontal scrape models are ideal for creamy, smooth textures such as vanilla and pistachio, as their mixing method promotes consistent aeration and silkiness. Choosing the right scraping technique enhances flavor integrity and texture tailored to specific ice cream styles.

Choosing the Right Ice Cream Maker Based on Scrape Style

Vertical scrape ice cream makers provide more consistent ingredient mixing by continuously redistributing the mixture from bottom to top, preventing uneven freezing and ensuring a smoother texture. Horizontal scrape machines typically freeze faster due to direct contact with cooled surfaces, but may result in less uniform mixing, potentially causing ice crystals or inconsistent flavor distribution. Selecting the right ice cream maker depends on prioritizing texture quality with vertical scrape technology or faster production speed offered by horizontal scrape models.

Vertical Scrape vs Horizontal Scrape for Ingredient Mixing Infographic

productvia.com

productvia.com