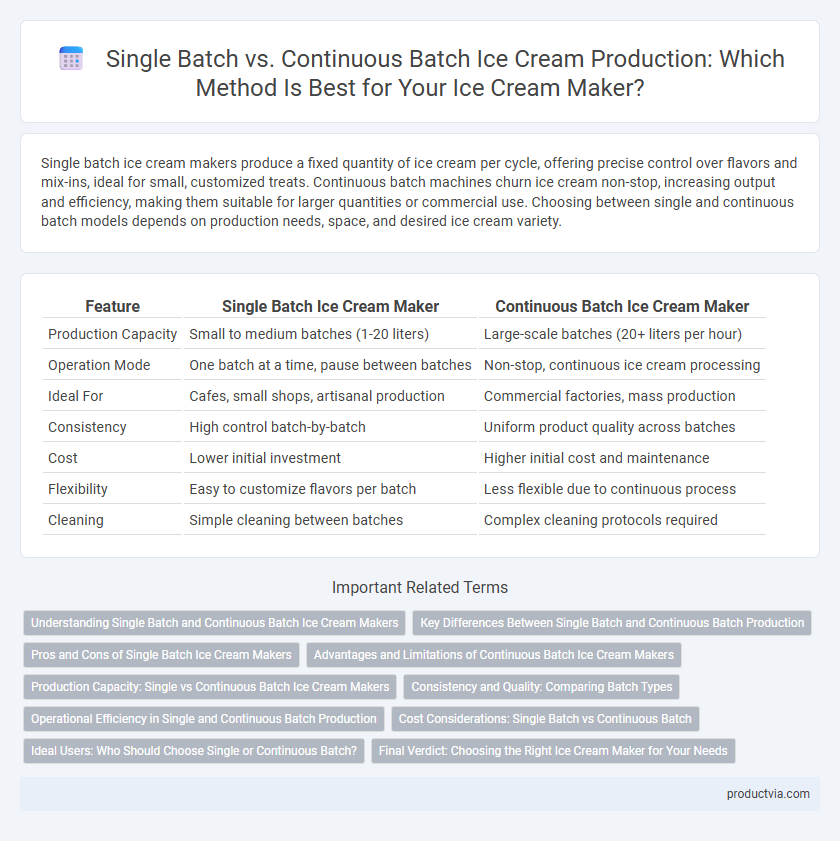

Single batch ice cream makers produce a fixed quantity of ice cream per cycle, offering precise control over flavors and mix-ins, ideal for small, customized treats. Continuous batch machines churn ice cream non-stop, increasing output and efficiency, making them suitable for larger quantities or commercial use. Choosing between single and continuous batch models depends on production needs, space, and desired ice cream variety.

Table of Comparison

| Feature | Single Batch Ice Cream Maker | Continuous Batch Ice Cream Maker |

|---|---|---|

| Production Capacity | Small to medium batches (1-20 liters) | Large-scale batches (20+ liters per hour) |

| Operation Mode | One batch at a time, pause between batches | Non-stop, continuous ice cream processing |

| Ideal For | Cafes, small shops, artisanal production | Commercial factories, mass production |

| Consistency | High control batch-by-batch | Uniform product quality across batches |

| Cost | Lower initial investment | Higher initial cost and maintenance |

| Flexibility | Easy to customize flavors per batch | Less flexible due to continuous process |

| Cleaning | Simple cleaning between batches | Complex cleaning protocols required |

Understanding Single Batch and Continuous Batch Ice Cream Makers

Single batch ice cream makers produce one batch at a time, allowing for precise control over ingredients and customization, making them ideal for small-scale or artisan production. Continuous batch ice cream makers operate by continuously freezing and mixing ice cream, enhancing efficiency and output for larger commercial operations. Understanding the differences between single batch and continuous batch ice cream makers is crucial for selecting the right equipment based on production volume and desired product consistency.

Key Differences Between Single Batch and Continuous Batch Production

Single batch ice cream production processes a fixed quantity of mix into ice cream before starting a new batch, allowing for greater flavor flexibility and customization. Continuous batch production runs non-stop, processing the mix without interruption, resulting in higher output and consistent texture ideal for mass production. Key differences include production volume, operational efficiency, and product uniformity.

Pros and Cons of Single Batch Ice Cream Makers

Single batch ice cream makers offer precise control over recipe customization and allow small-scale production without large equipment investments, making them ideal for home use and artisanal creations. However, their limited capacity restricts output volume, and frequent cleaning between batches can reduce overall efficiency. Compared to continuous batch machines, single batch models are less suited for high-volume production but excel in flexibility and simplicity.

Advantages and Limitations of Continuous Batch Ice Cream Makers

Continuous batch ice cream makers provide the advantage of producing large quantities of ice cream efficiently by maintaining a steady freezing and churning process, which ensures consistent texture and quality. They minimize downtime between batches and allow for automation, reducing labor costs and increasing overall production speed. However, continuous batch machines require significant initial investment, occupy more space, and may have limitations in handling diverse or small batch recipes compared to single batch machines.

Production Capacity: Single vs Continuous Batch Ice Cream Makers

Single batch ice cream makers produce limited quantities per cycle, making them ideal for small-scale or artisanal production, typically handling a few liters at a time. Continuous batch ice cream makers operate non-stop, significantly increasing production capacity to hundreds of liters per hour, suitable for commercial and industrial-scale operations. Choosing between single and continuous batch systems depends on the desired output volume and operational efficiency requirements.

Consistency and Quality: Comparing Batch Types

Single batch ice cream makers provide precise control over texture and flavor, ensuring a consistent product with every batch due to individualized processing. Continuous batch machines excel in large-scale production, maintaining uniformity through constant mixing and freezing processes but can occasionally sacrifice small-batch artisanal quality. Consistency and quality depend on production scale and desired end-product characteristics, with single batch favored for premium texture and continuous batch ideal for volume efficiency.

Operational Efficiency in Single and Continuous Batch Production

Single batch ice cream makers offer precise control over ingredient proportions and production size, minimizing waste and ensuring consistent product quality. Continuous batch machines enhance operational efficiency by producing large volumes without interruption, reducing labor costs and maximizing output in commercial settings. Selecting between single and continuous batch production depends on balancing flexibility in small-scale craftsmanship with the demands for high-volume efficiency and throughput.

Cost Considerations: Single Batch vs Continuous Batch

Single batch ice cream makers typically have lower upfront costs, making them suitable for small-scale or artisanal producers with limited budgets; however, their operational costs per unit are higher due to smaller batch sizes and longer production times. Continuous batch machines involve a higher initial investment but provide greater efficiency and lower per-unit costs for large-scale, high-volume production by continuously processing ice cream without interruption. Evaluating cost considerations depends on production volume, with single batch units favored for small runs and continuous batch systems optimized for maximizing output and minimizing long-term expenses.

Ideal Users: Who Should Choose Single or Continuous Batch?

Single batch ice cream makers are ideal for home users and small-scale producers seeking flexibility and variety in flavors with limited production volume. Continuous batch machines suit commercial operations requiring high output and consistent product quality to meet large customer demand. Selecting the right machine depends on production scale, flavor customization needs, and operational efficiency goals.

Final Verdict: Choosing the Right Ice Cream Maker for Your Needs

Single batch ice cream makers produce limited quantities per cycle, ideal for home use and small batches, while continuous batch machines efficiently handle large volumes, suited for commercial production. Factors such as production scale, frequency of use, and budget influence the decision between single and continuous batch models. Selecting the right ice cream maker hinges on balancing convenience, output capacity, and maintenance requirements to meet specific ice cream production needs.

Single batch vs continuous batch for ice cream production Infographic

productvia.com

productvia.com