Copper coils offer superior electrical conductivity compared to aluminum coils, resulting in higher induction efficiency and faster heating in induction stove pet applications. Aluminum coils, while lighter and more cost-effective, exhibit lower conductivity, which can reduce energy transfer efficiency and heating speed. Choosing copper coils enhances performance by maximizing energy use and providing consistent, rapid temperature control.

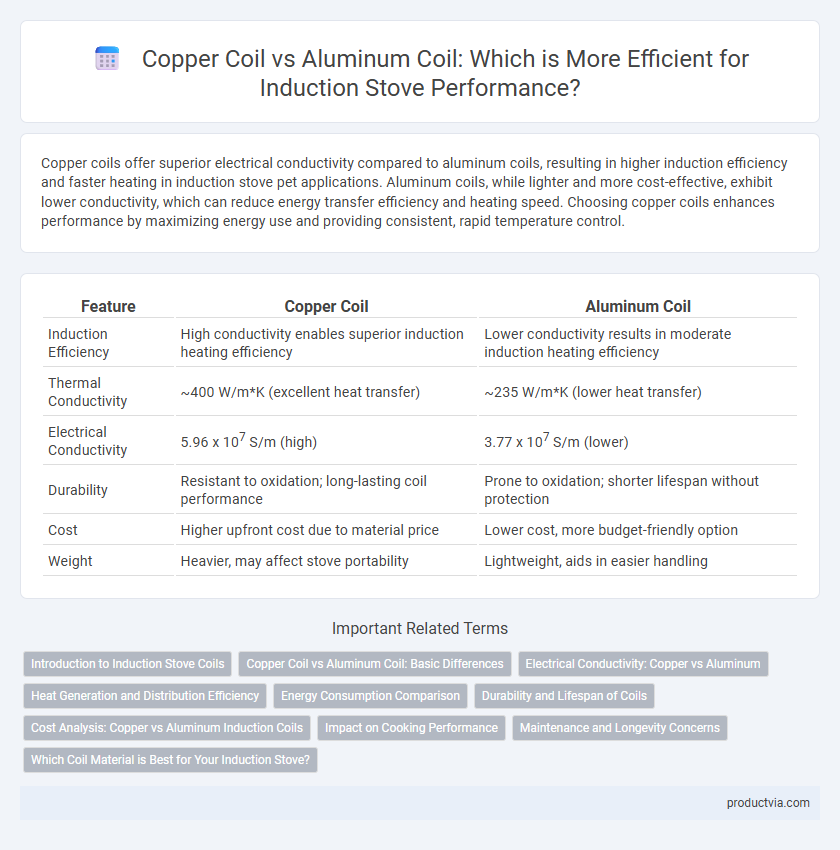

Table of Comparison

| Feature | Copper Coil | Aluminum Coil |

|---|---|---|

| Induction Efficiency | High conductivity enables superior induction heating efficiency | Lower conductivity results in moderate induction heating efficiency |

| Thermal Conductivity | ~400 W/m*K (excellent heat transfer) | ~235 W/m*K (lower heat transfer) |

| Electrical Conductivity | 5.96 x 107 S/m (high) | 3.77 x 107 S/m (lower) |

| Durability | Resistant to oxidation; long-lasting coil performance | Prone to oxidation; shorter lifespan without protection |

| Cost | Higher upfront cost due to material price | Lower cost, more budget-friendly option |

| Weight | Heavier, may affect stove portability | Lightweight, aids in easier handling |

Introduction to Induction Stove Coils

Copper coils offer superior electrical conductivity and thermal efficiency compared to aluminum coils, making them ideal for induction stove applications. The high conductivity of copper ensures faster heat generation and improved energy transfer to cookware, enhancing overall cooking performance. Aluminum coils, while lighter and less expensive, typically provide lower induction efficiency due to higher electrical resistance and reduced heat transfer capabilities.

Copper Coil vs Aluminum Coil: Basic Differences

Copper coils exhibit higher electrical conductivity compared to aluminum coils, enhancing induction stove efficiency by reducing energy loss and improving heat transfer. Aluminum coils, being lighter and less expensive, offer cost benefits but generally provide lower conductivity and durability than copper. The superior thermal and electrical properties of copper coils result in faster heating and more consistent cooking performance for induction stoves.

Electrical Conductivity: Copper vs Aluminum

Copper coils exhibit superior electrical conductivity at approximately 5.96 x 10^7 S/m, compared to aluminum's 3.77 x 10^7 S/m, resulting in more efficient energy transfer and reduced resistive losses in induction stoves. Higher conductivity in copper coils allows for faster heating and better performance under continuous electrical loads. Although aluminum coils are lighter and cost-effective, copper's enhanced conductivity significantly improves induction stove efficiency and durability.

Heat Generation and Distribution Efficiency

Copper coil in induction stoves provides superior heat generation due to its high electrical conductivity, which minimizes energy loss and enhances overall efficiency. Its excellent thermal conductivity ensures even heat distribution across the cooking surface, preventing hotspots and enabling precise temperature control. Aluminum coils, while lighter and less expensive, offer lower conductivity resulting in less efficient heat transfer and uneven heat distribution, potentially reducing cooking performance.

Energy Consumption Comparison

Copper coils exhibit superior electrical conductivity compared to aluminum, resulting in lower energy losses and higher induction stove efficiency. The enhanced conductivity of copper reduces heat generation within the coil, minimizing wasted energy and decreasing overall energy consumption during cooking. Aluminum coils, while lighter and less expensive, demonstrate higher resistance, leading to increased power usage and less efficient energy transfer.

Durability and Lifespan of Coils

Copper coils in induction stoves offer superior durability and longer lifespan due to their higher thermal conductivity and resistance to corrosion compared to aluminum coils. Aluminum coils may face quicker wear and oxidation, reducing efficiency and requiring more frequent replacements over time. The robust nature of copper coils ensures consistent performance and extended service life, making them a more reliable choice for induction efficiency.

Cost Analysis: Copper vs Aluminum Induction Coils

Copper induction coils offer superior electrical conductivity and thermal efficiency, enhancing induction stove performance, but they come with significantly higher initial costs compared to aluminum coils. Aluminum coils provide a cost-effective alternative with moderate conductivity, resulting in slightly lower induction efficiency yet reduced manufacturing expenses. Evaluating the total cost of ownership, including energy savings and coil lifespan, copper coils may deliver better long-term value despite their upfront investment.

Impact on Cooking Performance

Copper coils in induction stoves offer superior electrical conductivity, resulting in faster and more consistent heat generation compared to aluminum coils. This enhanced efficiency improves cooking performance by providing precise temperature control and quicker response times. Aluminum coils, while more affordable, generally produce less efficient heating, which can lead to uneven cooking and longer preparation times.

Maintenance and Longevity Concerns

Copper coils in induction stoves offer superior durability and better resistance to corrosion compared to aluminum coils, resulting in longer-lasting performance with less frequent maintenance. Aluminum coils, while more affordable, are prone to oxidation and damage over time, increasing the need for repairs and replacements. Choosing copper coils enhances induction efficiency by maintaining consistent electromagnetic conductivity and minimizing degradation, which contributes to extended stove lifespan.

Which Coil Material is Best for Your Induction Stove?

Copper coils provide superior electrical conductivity and heat transfer efficiency compared to aluminum coils, making them ideal for induction stoves. Copper's higher thermal conductivity ensures faster and more consistent heating, enhancing cooking performance and energy savings. Although aluminum coils are lighter and less expensive, they tend to have lower durability and efficiency for induction heating applications.

Copper coil vs Aluminum coil for induction efficiency Infographic

productvia.com

productvia.com