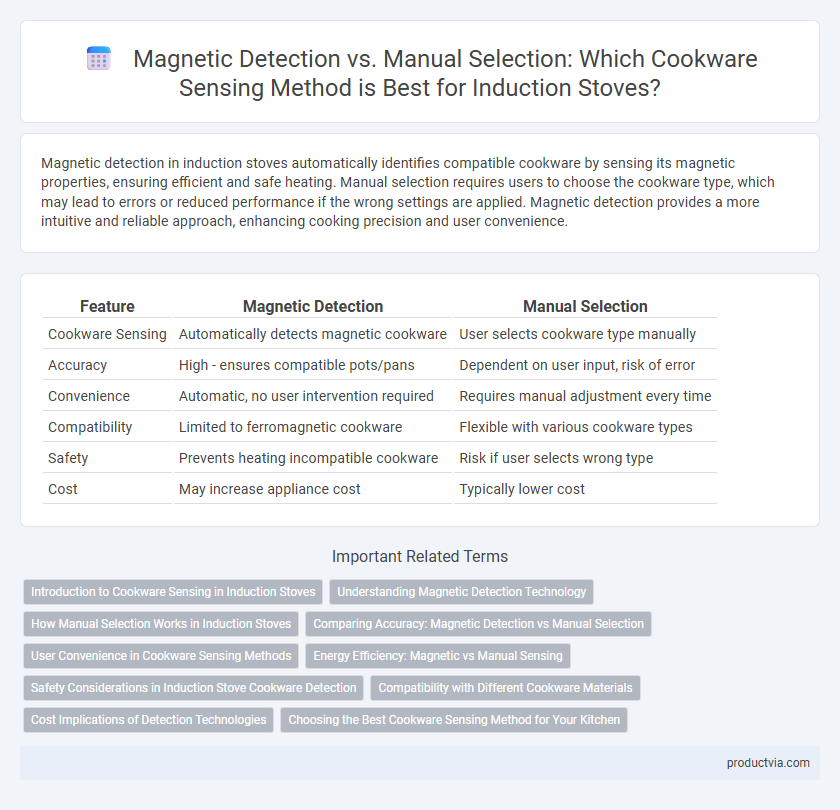

Magnetic detection in induction stoves automatically identifies compatible cookware by sensing its magnetic properties, ensuring efficient and safe heating. Manual selection requires users to choose the cookware type, which may lead to errors or reduced performance if the wrong settings are applied. Magnetic detection provides a more intuitive and reliable approach, enhancing cooking precision and user convenience.

Table of Comparison

| Feature | Magnetic Detection | Manual Selection |

|---|---|---|

| Cookware Sensing | Automatically detects magnetic cookware | User selects cookware type manually |

| Accuracy | High - ensures compatible pots/pans | Dependent on user input, risk of error |

| Convenience | Automatic, no user intervention required | Requires manual adjustment every time |

| Compatibility | Limited to ferromagnetic cookware | Flexible with various cookware types |

| Safety | Prevents heating incompatible cookware | Risk if user selects wrong type |

| Cost | May increase appliance cost | Typically lower cost |

Introduction to Cookware Sensing in Induction Stoves

Induction stoves use cookware sensing technology to detect compatible pots and pans for efficient heating. Magnetic detection relies on the presence of ferromagnetic materials, ensuring the cookware is induction-ready before activating the heating element. Manual selection allows users to specify cookware type, offering flexibility but requiring user knowledge to optimize cooking performance and energy use.

Understanding Magnetic Detection Technology

Magnetic detection technology in induction stoves uses sensors to identify the magnetic properties of cookware, ensuring efficient energy transfer only to compatible pots and pans. This automatic detection enhances safety by preventing the stove from heating non-magnetic or unsuitable materials, reducing energy waste and risks of accidents. Manual selection relies on user input, while magnetic detection offers precise, real-time recognition for optimal cooking performance.

How Manual Selection Works in Induction Stoves

Manual selection in induction stoves requires users to specify the cookware type via control settings, allowing the stove to adjust power output accordingly for optimal heating efficiency. Users typically select options such as pot size, material, or preset modes that match cookware characteristics, ensuring precise temperature control and energy conservation. This method relies on user input rather than automatic detection, providing flexibility but requiring proper selection to avoid performance issues.

Comparing Accuracy: Magnetic Detection vs Manual Selection

Magnetic detection in induction stoves offers superior accuracy by automatically sensing compatible cookware through electromagnetic fields, minimizing user error and ensuring optimal heating performance. Manual selection relies on the user to identify cookware type, which can lead to inaccuracies and inefficient energy use if incorrect settings are chosen. Studies show magnetic detection reduces misidentification by up to 90%, enhancing energy efficiency and safety in induction cooking.

User Convenience in Cookware Sensing Methods

Magnetic detection in induction stoves offers automatic identification of compatible cookware, enhancing user convenience by eliminating the need for manual input and reducing the risk of using inappropriate pots or pans. Manual selection requires users to specify cookware type, increasing the chance of errors and complicating the cooking process. Magnetic sensors streamline operation, providing seamless and efficient cookware recognition that optimizes safety and energy efficiency.

Energy Efficiency: Magnetic vs Manual Sensing

Magnetic detection in induction stoves automatically identifies compatible cookware by sensing the cookware's magnetic properties, ensuring optimal energy transfer and minimizing heat loss. Manual selection relies on user input to adjust settings, which can lead to inefficient energy use if incorrect cookware or settings are chosen. Magnetic sensing enhances energy efficiency by precisely matching power output to cookware presence, reducing unnecessary energy consumption compared to manual controls.

Safety Considerations in Induction Stove Cookware Detection

Magnetic detection in induction stoves enhances safety by automatically recognizing compatible cookware through its magnetic properties, preventing accidental heating of non-magnetic materials and reducing burn risks. Manual selection relies on user input to specify cookware type, which may lead to errors and unsafe heating if incompatible pots are mistakenly used. Incorporating magnetic detection technology significantly minimizes hazards like overheating and ensures precise cookware compatibility, optimizing safe operation in induction cooking.

Compatibility with Different Cookware Materials

Magnetic detection in induction stoves ensures optimal compatibility primarily with ferrous cookware such as cast iron and stainless steel, enabling automatic recognition and efficient heating. Manual selection allows users to specify cookware types, expanding compatibility to non-ferrous materials like aluminum or copper when paired with induction-compatible bases. Choosing magnetic detection improves ease of use and safety by preventing activation with incompatible cookware, while manual selection offers greater flexibility for diverse cookware materials.

Cost Implications of Detection Technologies

Magnetic detection technology in induction stoves offers cost efficiency by automating cookware sensing, reducing user error and energy waste, which lowers operational expenses over time. Manual selection requires less upfront investment but may increase long-term costs due to inefficiencies and potential stove damage from improper cookware choices. Choosing magnetic detection balances initial product pricing with savings in energy and maintenance, making it a more economically viable option for modern induction cooktops.

Choosing the Best Cookware Sensing Method for Your Kitchen

Magnetic detection in induction stoves ensures precise cookware compatibility by automatically sensing ferrous materials, enhancing safety and energy efficiency without user input. Manual selection allows users to specify cookware type, offering control but requiring careful attention to avoid errors and potential heating issues. Choosing between these methods depends on kitchen convenience preferences, with magnetic detection favored for seamless operation and manual selection suited for experienced cooks desiring customization.

Magnetic detection vs Manual selection for cookware sensing Infographic

productvia.com

productvia.com