An integrated butter melter in a popcorn maker ensures even distribution of melted butter directly during the popping process, enhancing flavor consistency and convenience. In contrast, external butter application requires post-popping drizzling or mixing, which can result in uneven coating and less efficient flavor absorption. Choosing an integrated butter melter elevates the overall popcorn experience by combining freshness and uniform taste in every batch.

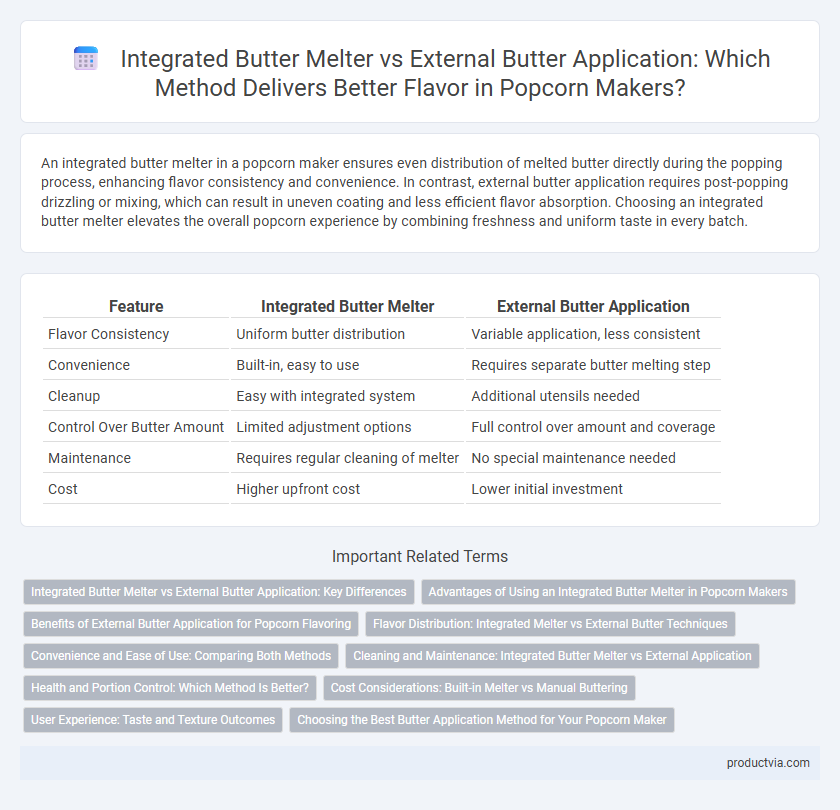

Table of Comparison

| Feature | Integrated Butter Melter | External Butter Application |

|---|---|---|

| Flavor Consistency | Uniform butter distribution | Variable application, less consistent |

| Convenience | Built-in, easy to use | Requires separate butter melting step |

| Cleanup | Easy with integrated system | Additional utensils needed |

| Control Over Butter Amount | Limited adjustment options | Full control over amount and coverage |

| Maintenance | Requires regular cleaning of melter | No special maintenance needed |

| Cost | Higher upfront cost | Lower initial investment |

Integrated Butter Melter vs External Butter Application: Key Differences

Integrated butter melters provide consistent, even melting and immediate flavor incorporation during the popping process, improving taste uniformity. External butter application allows precise control over the amount and type of butter added but risks uneven coating and delayed flavor distribution. Choosing between integrated and external options depends on desired flavor consistency, ease of use, and maintenance preferences in popcorn preparation.

Advantages of Using an Integrated Butter Melter in Popcorn Makers

An integrated butter melter in popcorn makers ensures even and consistent butter distribution, enhancing flavor absorption and overall taste. This built-in feature minimizes mess and cleanup compared to external butter application, which often results in uneven coating and wasted butter. The convenience of having the butter melted within the machine streamlines the popcorn-making process, saving time and improving user experience.

Benefits of External Butter Application for Popcorn Flavoring

External butter application allows precise control over the amount and distribution of butter, ensuring each popcorn piece is evenly coated for consistent flavor. It prevents sogginess commonly associated with integrated butter melters by adding butter after popping, maintaining popcorn's crisp texture. This method also offers flexibility to customize butter flavor intensity and incorporate various seasonings or oils, enhancing the overall tasting experience.

Flavor Distribution: Integrated Melter vs External Butter Techniques

Integrated butter melters in popcorn makers ensure even heat distribution, allowing melted butter to coat each popcorn kernel uniformly for consistent flavor. External butter application often results in uneven coverage, with some kernels absorbing more butter while others remain dry, leading to inconsistent taste profiles. Choosing an integrated butter melter enhances the overall flavor experience by delivering a balanced and thorough butter distribution directly during the popping process.

Convenience and Ease of Use: Comparing Both Methods

Integrated butter melters in popcorn makers offer superior convenience by allowing users to melt and distribute butter evenly during the popping process, eliminating the need for additional tools or steps. External butter application requires manual melting and pouring, which can lead to uneven flavor distribution and increased preparation time. Popcorn makers with built-in melters streamline the process, enhancing ease of use and delivering consistently buttery popcorn with minimal effort.

Cleaning and Maintenance: Integrated Butter Melter vs External Application

Integrated butter melters simplify cleaning and maintenance by containing melted butter within the popcorn maker, reducing mess and minimizing the risk of spills. External butter application requires separate containers and utensils, leading to increased cleaning tasks and potential residue buildup on multiple surfaces. Choosing an integrated butter melter enhances overall hygiene and streamlines maintenance routines for consistent popcorn flavoring.

Health and Portion Control: Which Method Is Better?

Integrated butter melters provide precise control over the amount of butter used, reducing the risk of excessive fat and calories compared to external butter application. External butter application often leads to uneven distribution and overuse, which can increase saturated fat intake and hinder portion control efforts. Health-conscious individuals benefit from integrated systems that allow for consistent, moderate butter flavoring, promoting better nutritional outcomes.

Cost Considerations: Built-in Melter vs Manual Buttering

Integrated butter melters in popcorn makers typically increase the initial cost but offer consistent, evenly distributed flavoring that reduces waste and saves money long-term. External butter application requires lower upfront investment but may lead to uneven coating, higher butter consumption, and increased labor costs. Choosing built-in melters balances upfront expenses with operational efficiency, while manual buttering favors budget-conscious buyers prioritizing flexibility.

User Experience: Taste and Texture Outcomes

An integrated butter melter ensures even distribution of melted butter throughout the popcorn, enhancing flavor consistency and maintaining a crisp texture. External butter application often results in uneven coating, creating soggy spots that compromise the popcorn's crunch. Users seeking optimal taste and texture benefit from the seamless blend of warmth and butter provided by integrated systems.

Choosing the Best Butter Application Method for Your Popcorn Maker

Choosing the best butter application method for your popcorn maker depends on convenience and flavor control. Integrated butter melters evenly distribute melted butter during popping, enhancing flavor absorption and reducing mess; however, external butter application allows customization with various butter types and seasoning amounts added after popping. Consider the balance between ease of use and flavor precision to select the ideal method for your popcorn experience.

Integrated butter melter vs external butter application for flavoring Infographic

productvia.com

productvia.com