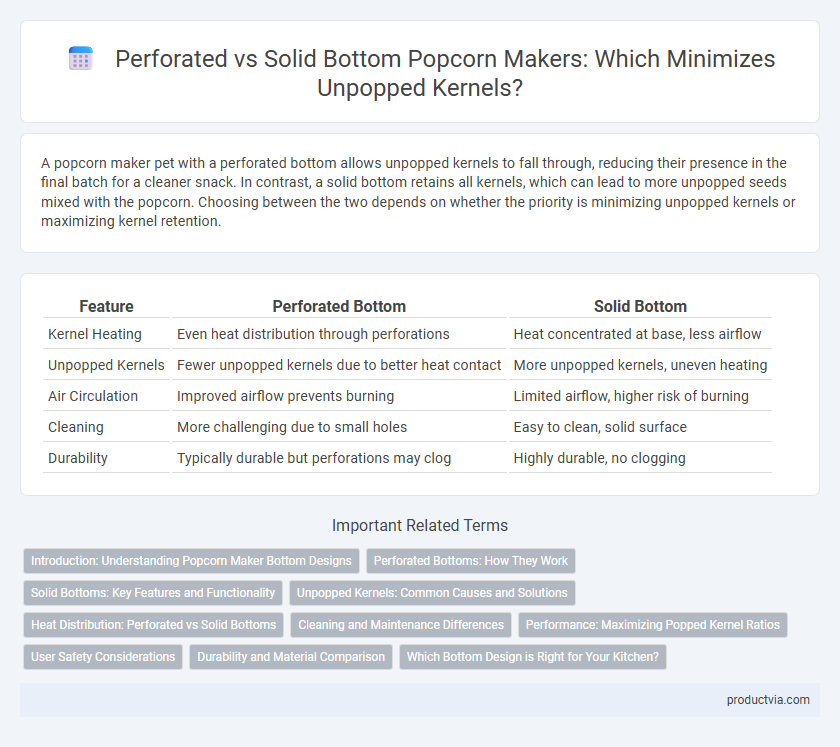

A popcorn maker pet with a perforated bottom allows unpopped kernels to fall through, reducing their presence in the final batch for a cleaner snack. In contrast, a solid bottom retains all kernels, which can lead to more unpopped seeds mixed with the popcorn. Choosing between the two depends on whether the priority is minimizing unpopped kernels or maximizing kernel retention.

Table of Comparison

| Feature | Perforated Bottom | Solid Bottom |

|---|---|---|

| Kernel Heating | Even heat distribution through perforations | Heat concentrated at base, less airflow |

| Unpopped Kernels | Fewer unpopped kernels due to better heat contact | More unpopped kernels, uneven heating |

| Air Circulation | Improved airflow prevents burning | Limited airflow, higher risk of burning |

| Cleaning | More challenging due to small holes | Easy to clean, solid surface |

| Durability | Typically durable but perforations may clog | Highly durable, no clogging |

Introduction: Understanding Popcorn Maker Bottom Designs

Perforated bottom popcorn makers allow heat circulation and prevent moisture buildup, enhancing even popping and reducing unpopped kernels. Solid bottom designs retain heat uniformly for consistent cooking but may trap moisture, increasing the risk of kernel scorching. Choosing between perforated and solid bottoms impacts popcorn quality by balancing heat distribution and kernel moisture control.

Perforated Bottoms: How They Work

Perforated bottoms in popcorn makers allow hot air to circulate directly under the kernels, ensuring even heat distribution and preventing burning. The small holes facilitate optimal airflow, which helps pop more kernels efficiently by maintaining consistent temperature and preventing moisture buildup. This design reduces the number of unpopped kernels by promoting uniform cooking and reducing hotspots.

Solid Bottoms: Key Features and Functionality

Solid bottom popcorn makers provide uniform heat distribution, minimizing hotspots that cause unpopped kernels. The continuous metal surface enhances oil retention and heat conduction, ensuring kernels pop fully and evenly. This design reduces kernel waste and maximizes popping efficiency for a better snack experience.

Unpopped Kernels: Common Causes and Solutions

Perforated bottom popcorn makers allow unpopped kernels to escape through the holes, reducing the number of hard, leftover kernels in the bowl. Solid bottom designs tend to trap unpopped kernels, leading to a higher count of these tough remnants after popping. To minimize unpopped kernels, choose a perforated bottom model and ensure even heat distribution for consistent popping.

Heat Distribution: Perforated vs Solid Bottoms

Perforated-bottom popcorn makers excel in heat distribution by allowing hot air to circulate evenly around kernels, reducing unpopped kernels and burn risk. Solid-bottom popcorn makers concentrate heat through direct contact, which can create hot spots leading to uneven popping and more unpopped kernels. Optimal heat distribution is crucial for maximizing kernel pop rate and achieving consistent popcorn quality.

Cleaning and Maintenance Differences

Perforated bottom popcorn makers allow unpopped kernels to fall through holes, reducing residue buildup and simplifying cleaning by preventing kernels from sticking to the surface. Solid bottom models trap unpopped kernels and oil, leading to increased residue and frequent, more intensive cleaning efforts to maintain hygiene. Choosing a perforated bottom improves maintenance efficiency by minimizing kernel accumulation and oil residue.

Performance: Maximizing Popped Kernel Ratios

A perforated bottom in a popcorn maker enhances airflow and heat distribution, resulting in a higher popped kernel ratio by allowing unpopped kernels to spin freely and heat more evenly. Solid bottoms can trap moisture and restrict circulation, often causing uneven heating and a greater number of unpopped kernels. Optimizing kernel contact with heat and air through perforation ensures maximum performance and minimal waste.

User Safety Considerations

Perforated bottom popcorn makers allow unpopped kernels to fall through, reducing the risk of overheating and burning, which enhances user safety by preventing hot kernel explosions. Solid bottom models retain all kernels, increasing the chance of kernel build-up and potential heat hazards that may cause burns or fires. Opting for perforated bottoms minimizes direct contact with hot, unpopped kernels, providing safer popcorn preparation.

Durability and Material Comparison

Perforated bottom popcorn makers typically use stainless steel or aluminum, offering superior heat conduction and durability while preventing unpopped kernels from burning. Solid bottom designs, often made from cast iron or non-stick coated metal, provide even heating but may trap moisture, leading to uneven popping and potential wear over time. Choosing stainless steel with a perforated bottom combines resilience against rust and warping with efficient kernel popping performance.

Which Bottom Design is Right for Your Kitchen?

Perforated bottom popcorn makers allow steam to escape, reducing moisture buildup and resulting in crispier popcorn with fewer unpopped kernels. Solid bottom designs retain heat evenly, but may trap moisture, potentially causing soggy popcorn and more unpopped kernels. Choose a perforated bottom for drier, fluffier popcorn, or a solid bottom if even heating is preferred in your kitchen setup.

Perforated bottom vs solid bottom for unpopped kernels Infographic

productvia.com

productvia.com