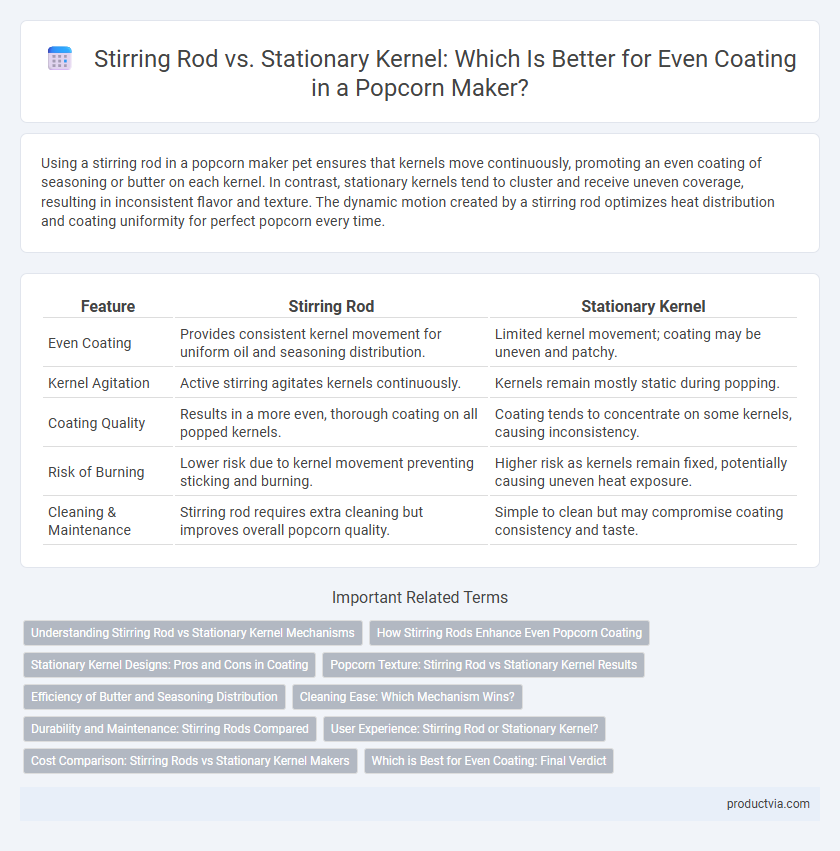

Using a stirring rod in a popcorn maker pet ensures that kernels move continuously, promoting an even coating of seasoning or butter on each kernel. In contrast, stationary kernels tend to cluster and receive uneven coverage, resulting in inconsistent flavor and texture. The dynamic motion created by a stirring rod optimizes heat distribution and coating uniformity for perfect popcorn every time.

Table of Comparison

| Feature | Stirring Rod | Stationary Kernel |

|---|---|---|

| Even Coating | Provides consistent kernel movement for uniform oil and seasoning distribution. | Limited kernel movement; coating may be uneven and patchy. |

| Kernel Agitation | Active stirring agitates kernels continuously. | Kernels remain mostly static during popping. |

| Coating Quality | Results in a more even, thorough coating on all popped kernels. | Coating tends to concentrate on some kernels, causing inconsistency. |

| Risk of Burning | Lower risk due to kernel movement preventing sticking and burning. | Higher risk as kernels remain fixed, potentially causing uneven heat exposure. |

| Cleaning & Maintenance | Stirring rod requires extra cleaning but improves overall popcorn quality. | Simple to clean but may compromise coating consistency and taste. |

Understanding Stirring Rod vs Stationary Kernel Mechanisms

A stirring rod in a popcorn maker continuously moves kernels, promoting even heat distribution and consistent coating by preventing clumping. In contrast, stationary kernels rely on the motion of hot air or oil to coat each kernel individually, which may result in uneven seasoning. Understanding these mechanisms helps optimize popcorn texture and flavor by selecting the appropriate method for uniform popcorn seasoning.

How Stirring Rods Enhance Even Popcorn Coating

Stirring rods in popcorn makers ensure kernels move continuously during popping, preventing clumps and promoting uniform heat distribution. This consistent agitation allows seasoning and oil to coat each kernel evenly, enhancing flavor and texture. In contrast, stationary kernels often result in uneven coating, with some pieces underseasoned or burnt.

Stationary Kernel Designs: Pros and Cons in Coating

Stationary kernel designs in popcorn makers offer the advantage of minimizing kernel breakage, preserving integrity during the popping process for even coating distribution. However, uneven heat exposure can result in inconsistent popping and coating, potentially leading to clusters of unpopped kernels. Optimizing airflow and temperature control is critical to improving the coating uniformity in stationary kernel systems.

Popcorn Texture: Stirring Rod vs Stationary Kernel Results

The stirring rod mechanism in popcorn makers promotes consistent kernel movement, ensuring even heat distribution and uniform coating, which results in a crispier and fluffier texture. In contrast, stationary kernels often cause uneven popping and coating, leading to burnt spots and a denser, less airy popcorn. Optimizing stirring rod speed directly enhances texture quality by reducing kernel clumping and improving overall coating coverage.

Efficiency of Butter and Seasoning Distribution

A stirring rod in popcorn makers ensures even coating by constantly agitating kernels, promoting uniform butter and seasoning distribution. Stationary kernel methods often result in uneven coverage, causing inconsistent flavor in batches. Efficient butter and seasoning application relies heavily on the stirring mechanism to maximize taste and reduce waste.

Cleaning Ease: Which Mechanism Wins?

A stirring rod mechanism in popcorn makers promotes even coating by continuously agitating kernels, reducing clumps and ensuring uniform flavor distribution. Cleaning a stirring rod system can be more labor-intensive due to moving parts and potential buildup in crevices. Stationary kernel designs typically offer simpler cleaning processes, as fewer mechanical components trap residue, making maintenance faster and more straightforward for users.

Durability and Maintenance: Stirring Rods Compared

Stirring rods in popcorn makers offer enhanced durability due to their metal construction, resisting wear and tear from constant motion and heat exposure. Maintenance of stirring rods is more demanding, requiring regular cleaning to prevent kernel residue buildup that can affect performance and coating evenness. Stationary kernels minimize mechanical wear but often lead to uneven coating and require less maintenance, making stirring rods more effective for consistent, high-quality popcorn preparation despite higher upkeep.

User Experience: Stirring Rod or Stationary Kernel?

A stirring rod in popcorn makers ensures even coating by continuously moving kernels, preventing clumps and promoting consistent heat distribution for a crisp, flavorful finish. Stationary kernel methods rely on static positioning, which can lead to uneven seasoning and partially popped kernels, diminishing overall taste and texture quality. Users seeking uniform popcorn with minimal burnt pieces benefit more from stirring rod designs, enhancing the snack preparation experience significantly.

Cost Comparison: Stirring Rods vs Stationary Kernel Makers

Stirring rod popcorn makers generally incur higher production and maintenance costs due to the mechanical complexity involved in continually agitating kernels for even coating, resulting in increased energy consumption and potential wear on moving parts. Stationary kernel machines feature a simpler design with fewer moving components, significantly reducing manufacturing expenses and maintenance needs, which translates into lower overall costs. For businesses prioritizing cost-efficiency without sacrificing coating uniformity, stationary kernel popcorn makers offer a more economical solution compared to stirring rod models.

Which is Best for Even Coating: Final Verdict

A stirring rod in a popcorn maker ensures consistent agitation, promoting even exposure to heat and oil for uniform popcorn coating. Stationary kernels rely on heat distribution without movement, often resulting in uneven seasoning and less consistent texture. For optimal even coating, a popcorn maker with a stirring rod is the best choice, enhancing flavor adhesion and kernel crispness.

Stirring rod vs stationary kernel for even coating Infographic

productvia.com

productvia.com