A popcorn maker pet with a nonstick coating offers effortless cleaning as popcorn and oil residues slide off easily, preventing stubborn buildup. In contrast, an uncoated interior may require more intensive scrubbing to remove stuck-on kernels and grease, increasing maintenance time. Choosing a nonstick surface enhances convenience and keeps the appliance hygienic with minimal effort.

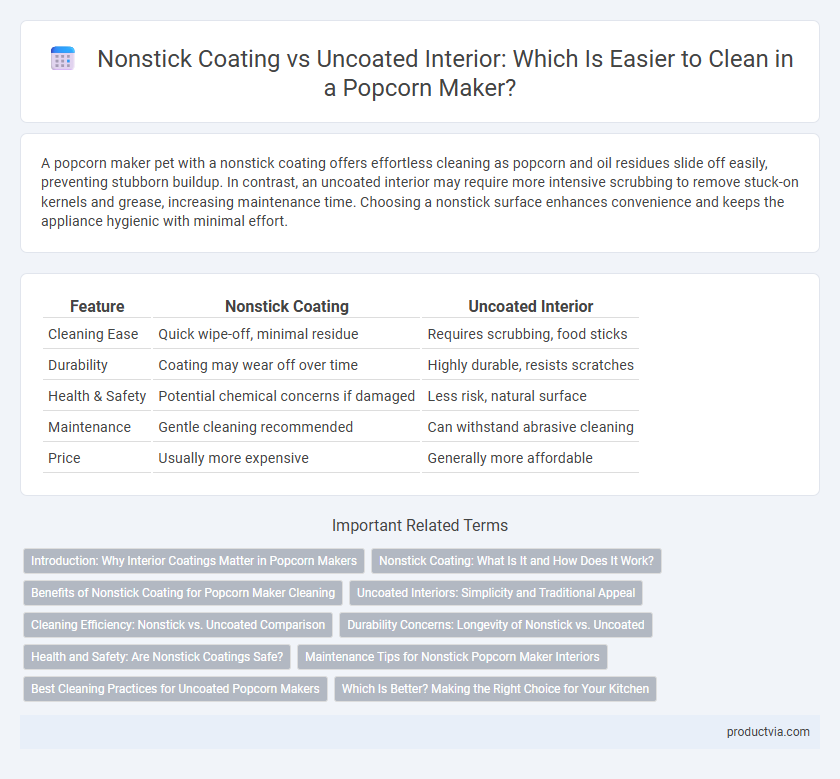

Table of Comparison

| Feature | Nonstick Coating | Uncoated Interior |

|---|---|---|

| Cleaning Ease | Quick wipe-off, minimal residue | Requires scrubbing, food sticks |

| Durability | Coating may wear off over time | Highly durable, resists scratches |

| Health & Safety | Potential chemical concerns if damaged | Less risk, natural surface |

| Maintenance | Gentle cleaning recommended | Can withstand abrasive cleaning |

| Price | Usually more expensive | Generally more affordable |

Introduction: Why Interior Coatings Matter in Popcorn Makers

Interior coatings in popcorn makers significantly impact ease of cleaning and maintenance, with nonstick coatings preventing kernels and oil from adhering to the surface. Nonstick interiors reduce residue buildup, allowing for quicker cleanup and prolonged appliance lifespan. Uncoated interiors may require more intensive scrubbing, increasing the risk of scratches and wear over time.

Nonstick Coating: What Is It and How Does It Work?

Nonstick coating is a specialized layer applied to the interior surface of a popcorn maker designed to prevent popcorn and oil from sticking during cooking, enhancing easy cleaning. This coating typically consists of materials like polytetrafluoroethylene (PTFE), which creates a smooth, low-friction surface that resists adhesion of food residues. By minimizing sticking, nonstick interiors reduce the need for scrubbing and allow for quick, hassle-free maintenance compared to uncoated surfaces.

Benefits of Nonstick Coating for Popcorn Maker Cleaning

Nonstick coating in popcorn makers ensures effortless cleaning by preventing kernels and oil from sticking to the interior surface, significantly reducing scrubbing time. This coating enhances durability by resisting stains and buildup, maintaining the appliance's pristine condition for longer periods. Users benefit from improved hygiene and quicker maintenance, making popcorn machines with nonstick interiors a convenient choice for frequent use.

Uncoated Interiors: Simplicity and Traditional Appeal

Uncoated interiors in popcorn makers offer a simple, traditional appeal that attracts enthusiasts seeking a natural cooking surface free from synthetic layers. These surfaces prevent chemical wear and can be cleaned with basic methods such as warm water and mild soap, avoiding concerns of flaking nonstick coatings. The robust design of uncoated interiors ensures durability while maintaining popcorn flavor integrity without risking damage from abrasive sponges or harsh cleaners.

Cleaning Efficiency: Nonstick vs. Uncoated Comparison

Nonstick coatings on popcorn makers significantly enhance cleaning efficiency by preventing popcorn residue from adhering to interior surfaces, reducing scrubbing time and effort. Uncoated interiors often require soaking and more vigorous cleaning to remove stuck kernels and oil buildup, increasing maintenance time. Consumers seeking hassle-free cleanup typically prefer nonstick interiors for their superior resistance to residue and ease of upkeep.

Durability Concerns: Longevity of Nonstick vs. Uncoated

Nonstick coatings on popcorn makers provide effortless cleaning due to their smooth surface that prevents popcorn residue from sticking. However, durability concerns arise as nonstick layers can degrade or peel over time, reducing the appliance's lifespan. In contrast, uncoated interiors, typically made of stainless steel or aluminum, offer greater longevity and resistance to wear but may require more rigorous scrubbing during cleaning.

Health and Safety: Are Nonstick Coatings Safe?

Nonstick coatings on popcorn makers offer easy cleaning by preventing food from sticking, reducing the need for excessive scrubbing that can degrade the surface. However, concerns arise over chemical safety, as older nonstick materials like PFOA have been linked to health risks, prompting manufacturers to adopt safer alternatives such as ceramic or PTFE coatings free from harmful substances. Uncoated interiors require more effort to clean but avoid potential chemical exposure, making them a preferred choice for health-conscious consumers prioritizing safety and natural materials.

Maintenance Tips for Nonstick Popcorn Maker Interiors

Nonstick coating in popcorn makers significantly reduces residue buildup, allowing for effortless cleaning with a soft cloth and mild detergent. Avoid using abrasive sponges or harsh chemicals to maintain the integrity of the nonstick surface and prolong the lifespan of the appliance. Regular gentle cleaning after each use prevents oil and popcorn residue accumulation, ensuring consistent performance and longevity of the popcorn maker.

Best Cleaning Practices for Uncoated Popcorn Makers

Uncoated popcorn makers require diligent cleaning to prevent residue buildup and maintain performance. Best practices include immediate removal of oil and kernels with warm, soapy water and a non-abrasive sponge, followed by thorough drying to avoid rust. Regular deep cleaning with mild vinegar solutions effectively removes stubborn residues without damaging the surface.

Which Is Better? Making the Right Choice for Your Kitchen

Nonstick coating in popcorn makers ensures effortless cleaning by preventing kernels and oils from sticking, making it ideal for frequent use and quick maintenance. Uncoated interiors, often stainless steel or aluminum, offer durability and resist chemical wear but may require more scrubbing to remove residue effectively. Choosing between nonstick and uncoated depends on your cleaning preferences and how often you use the popcorn maker; nonstick suits ease and convenience, while uncoated favors longevity and natural cooking surfaces.

Nonstick Coating vs Uncoated Interior for Easy Cleaning Infographic

productvia.com

productvia.com