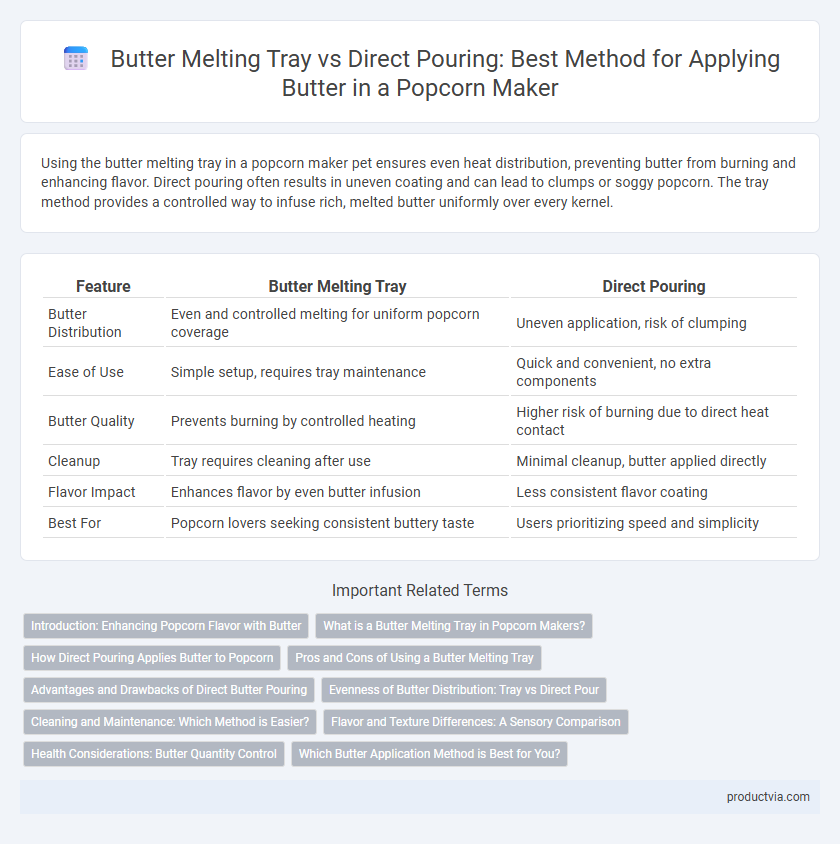

Using the butter melting tray in a popcorn maker pet ensures even heat distribution, preventing butter from burning and enhancing flavor. Direct pouring often results in uneven coating and can lead to clumps or soggy popcorn. The tray method provides a controlled way to infuse rich, melted butter uniformly over every kernel.

Table of Comparison

| Feature | Butter Melting Tray | Direct Pouring |

|---|---|---|

| Butter Distribution | Even and controlled melting for uniform popcorn coverage | Uneven application, risk of clumping |

| Ease of Use | Simple setup, requires tray maintenance | Quick and convenient, no extra components |

| Butter Quality | Prevents burning by controlled heating | Higher risk of burning due to direct heat contact |

| Cleanup | Tray requires cleaning after use | Minimal cleanup, butter applied directly |

| Flavor Impact | Enhances flavor by even butter infusion | Less consistent flavor coating |

| Best For | Popcorn lovers seeking consistent buttery taste | Users prioritizing speed and simplicity |

Introduction: Enhancing Popcorn Flavor with Butter

Butter melting trays provide a controlled and even heat source that ensures butter melts uniformly, enhancing flavor distribution across popcorn. Direct pouring often leads to uneven butter application, causing some kernels to taste richer while others remain dry. Using a butter melting tray optimizes the buttery coating, resulting in consistently flavorful popcorn.

What is a Butter Melting Tray in Popcorn Makers?

A butter melting tray in popcorn makers is a dedicated compartment designed to evenly melt butter while the popcorn pops, ensuring smooth and consistent butter distribution. This tray prevents hot butter from splattering and allows it to drip gently over the popcorn, enhancing flavor without making the kernels soggy. Compared to direct pouring, the melting tray offers better control and convenience for a perfectly buttery snack.

How Direct Pouring Applies Butter to Popcorn

Direct pouring applies butter to popcorn by evenly distributing melted butter over the entire batch, ensuring consistent flavor. This method minimizes clumping and prevents sogginess by allowing excess butter to drip away. The result is a perfectly coated popcorn with enhanced taste and optimal texture.

Pros and Cons of Using a Butter Melting Tray

A butter melting tray for popcorn ensures even heating and prevents burning, enhancing flavor consistency compared to direct pouring. It allows controlled butter distribution, reducing the risk of soggy popcorn and messes. However, it requires extra cleaning and setup time, which may not be ideal for fast-paced environments.

Advantages and Drawbacks of Direct Butter Pouring

Direct butter pouring onto popcorn enhances flavor by evenly coating each kernel without the need for additional trays, saving time and simplifying the popcorn-making process. This method, however, risks uneven melting and potential scorching if the butter is too hot or poured too quickly, which can create greasy patches or burnt spots. While it eliminates the need for extra components like a butter melting tray, direct pouring demands careful temperature control and technique to maintain optimal butter consistency and popcorn texture.

Evenness of Butter Distribution: Tray vs Direct Pour

Butter melting trays in popcorn makers ensure uniform temperature control, resulting in even butter melting and consistent distribution over the popcorn surface. Direct pouring often leads to uneven butter application, with some areas overly saturated while others remain dry, affecting taste and texture. Using a melting tray promotes balanced butter coverage, enhancing flavor and customer satisfaction.

Cleaning and Maintenance: Which Method is Easier?

The butter melting tray in a popcorn maker allows for easier cleaning since it contains melted butter in a removable compartment, preventing greasy spills on the machine. Direct pouring often results in butter dripping onto the heating element and internal components, requiring more intensive maintenance to avoid residue buildup. Using a butter tray reduces the risk of clogged parts and simplifies routine cleaning, extending the popcorn maker's lifespan.

Flavor and Texture Differences: A Sensory Comparison

Butter melting trays in popcorn makers provide even heat distribution, resulting in smoothly melted butter that enhances flavor absorption and delivers a rich, creamy texture. Direct pouring of melted butter onto popcorn often creates uneven coating and can cause sogginess or dryness, negatively impacting mouthfeel and overall taste. Sensory evaluations reveal that popcorn treated with butter from a melting tray offers a more balanced buttery flavor and consistently crisp texture compared to direct pouring methods.

Health Considerations: Butter Quantity Control

Using a butter melting tray with a popcorn maker enables precise control over butter quantity, reducing excess fat intake and minimizing calorie consumption. Direct pouring often leads to uneven butter distribution, potentially increasing the overall butter amount and saturated fat levels in the popcorn. Controlled butter application promotes healthier snacking by managing portion sizes and preserving nutritional balance.

Which Butter Application Method is Best for You?

A butter melting tray offers precise control and even distribution, ensuring popcorn is consistently coated without sogginess. Direct pouring is faster and simpler but risks uneven coverage and clumping. Choose a melting tray for a professional finish or direct pouring for convenience and speed.

Butter melting tray vs direct pouring for butter application Infographic

productvia.com

productvia.com