A stirring rod in a popcorn maker pet ensures even kernel popping by continuously agitating the kernels, preventing them from burning or sticking to the heating surface. Stationary heating often leads to uneven heat distribution, causing some kernels to burn while others remain unpopped. Using a stirring mechanism promotes uniform heat exposure, resulting in consistently fluffy and fully popped popcorn.

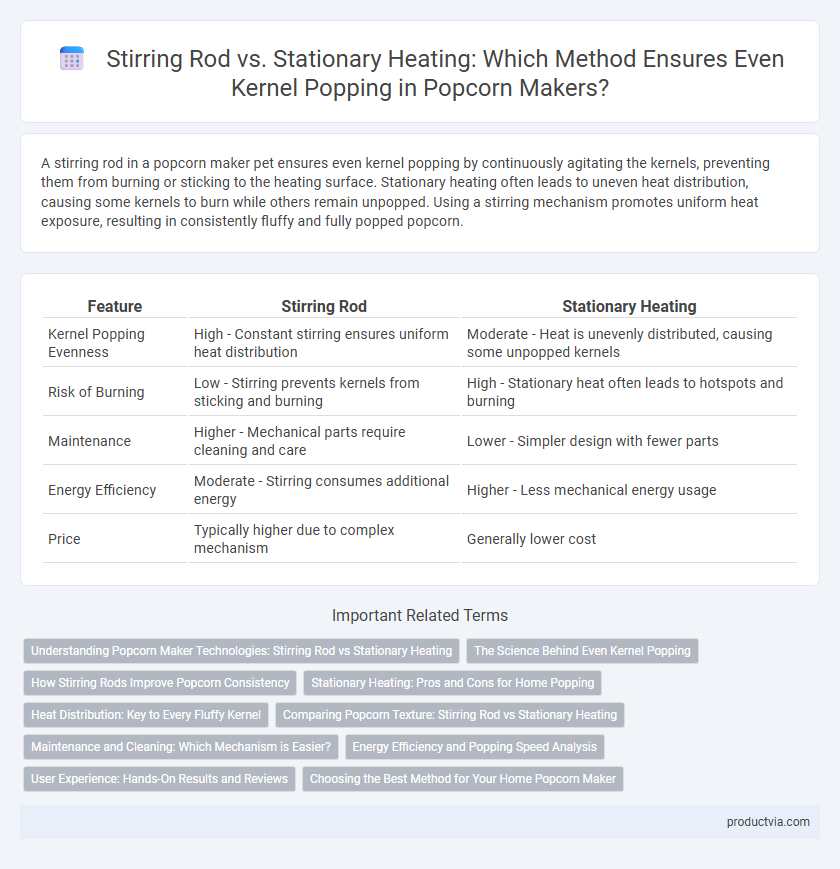

Table of Comparison

| Feature | Stirring Rod | Stationary Heating |

|---|---|---|

| Kernel Popping Evenness | High - Constant stirring ensures uniform heat distribution | Moderate - Heat is unevenly distributed, causing some unpopped kernels |

| Risk of Burning | Low - Stirring prevents kernels from sticking and burning | High - Stationary heat often leads to hotspots and burning |

| Maintenance | Higher - Mechanical parts require cleaning and care | Lower - Simpler design with fewer parts |

| Energy Efficiency | Moderate - Stirring consumes additional energy | Higher - Less mechanical energy usage |

| Price | Typically higher due to complex mechanism | Generally lower cost |

Understanding Popcorn Maker Technologies: Stirring Rod vs Stationary Heating

The stirring rod mechanism in popcorn makers ensures even kernel popping by continuously agitating the kernels, preventing them from sticking and burning. Stationary heating relies on a constant heat source without movement, which can cause uneven heat distribution and increase the chance of unpopped kernels. Choosing a popcorn maker with a stirring rod technology enhances uniform heat exposure, resulting in more consistent popping performance.

The Science Behind Even Kernel Popping

The science behind even kernel popping centers on consistent heat distribution and kernel movement. Stirring rods actively agitate kernels, preventing clumping and ensuring uniform exposure to heat, which reduces unpopped kernels and burnt spots. Stationary heating relies solely on conductive heat transfer, often leading to uneven temperature zones and less efficient popping compared to dynamic stirring methods.

How Stirring Rods Improve Popcorn Consistency

Stirring rods in popcorn makers enhance kernel popping consistency by continuously agitating the kernels, preventing them from sticking and burning. This constant motion distributes heat evenly, ensuring that more kernels pop fully and reducing the number of unpopped kernels. In contrast, stationary heating methods often cause uneven heat distribution, resulting in inconsistent popping and increased kernel waste.

Stationary Heating: Pros and Cons for Home Popping

Stationary heating in popcorn makers offers consistent temperature control, reducing the risk of burning kernels compared to uneven heating methods. However, without a stirring rod to agitate the kernels, some may remain unpopped or scorch at the bottom, affecting overall popping efficiency. This method suits users who prioritize quieter operation and simplicity but may require occasional manual shaking to achieve even popping results.

Heat Distribution: Key to Every Fluffy Kernel

The stirring rod ensures uniform heat distribution by continuously moving the kernels, preventing hot spots and allowing each kernel to pop evenly. In contrast, stationary heating relies solely on conduction from the base, which can lead to uneven temperature zones and an increased risk of burning or unpopped kernels. Optimal popcorn makers use stirring mechanisms to maintain consistent heat flow, resulting in a higher yield of fluffy, fully popped kernels.

Comparing Popcorn Texture: Stirring Rod vs Stationary Heating

A stirring rod in a popcorn maker ensures even heat distribution by continuously moving kernels, resulting in consistently popped, fluffy popcorn with minimal burning. Stationary heating often causes uneven heat exposure, leading to some kernels overcooked and others underpopped, which affects overall texture and flavor. Comparative studies show stirring rod models produce superior, uniform popcorn texture, enhancing the snacking experience.

Maintenance and Cleaning: Which Mechanism is Easier?

Stirring rod mechanisms in popcorn makers require regular cleaning to prevent buildup of oil and residue on the rod and surrounding surfaces, often necessitating disassembly for thorough maintenance. Stationary heating models generally offer easier cleaning since there are fewer moving parts, reducing areas where debris can accumulate and simplifying wipe-down processes. For long-term ease of maintenance, stationary heating units are typically preferred due to their straightforward, less labor-intensive cleaning requirements.

Energy Efficiency and Popping Speed Analysis

A popcorn maker with a stirring rod ensures more uniform kernel heating, reducing the number of unpopped kernels and enhancing energy efficiency by minimizing repeated heating cycles. Stationary heating relies on passive heat distribution, which often results in uneven popping and longer popping times, increasing overall energy consumption. Studies show that stirring mechanisms can reduce popping time by up to 30%, optimizing both energy use and kernel yield.

User Experience: Hands-On Results and Reviews

Users report that popcorn makers with a stirring rod consistently deliver more evenly popped kernels compared to stationary heating models, reducing the number of unpopped kernels and burnt pieces. Reviews highlight that the stirring rod ensures continuous movement during cooking, which enhances heat distribution and improves popping efficiency. Hands-on results emphasize smoother user experience with less manual intervention and higher yield of fluffy popcorn.

Choosing the Best Method for Your Home Popcorn Maker

Using a stirring rod in a popcorn maker promotes uniform kernel heating by continuously agitating the kernels, preventing burning and ensuring consistent popping. Stationary heating relies on even heat distribution without movement, which can result in uneven cooking and more unpopped kernels. For home popcorn makers, stirring rods typically deliver better results, enhancing texture and maximizing popped corn yield.

Stirring rod vs stationary heating for even kernel popping Infographic

productvia.com

productvia.com