The choice between a stirring rod and a fixed plate for kernel agitation in popcorn makers pet significantly impacts popping efficiency and kernel distribution. Stirring rods actively rotate, ensuring even heat exposure and minimizing unpopped kernels, while fixed plates rely on less dynamic movement, often leading to uneven popping. Optimizing agitation with a stirring rod enhances overall pop quality and reduces waste.

Table of Comparison

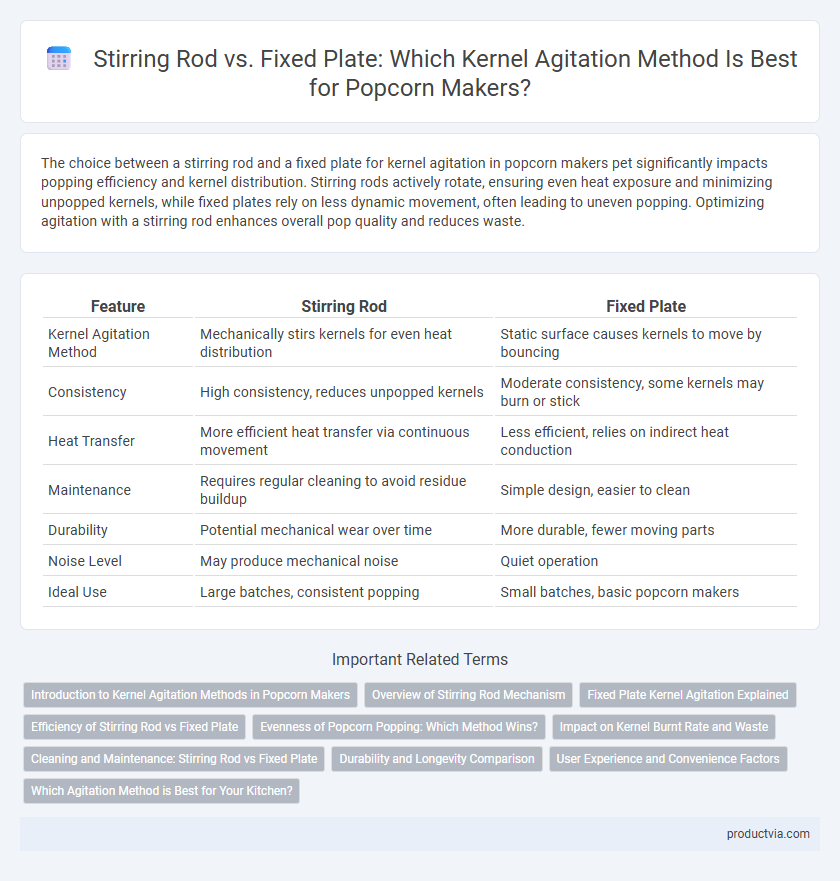

| Feature | Stirring Rod | Fixed Plate |

|---|---|---|

| Kernel Agitation Method | Mechanically stirs kernels for even heat distribution | Static surface causes kernels to move by bouncing |

| Consistency | High consistency, reduces unpopped kernels | Moderate consistency, some kernels may burn or stick |

| Heat Transfer | More efficient heat transfer via continuous movement | Less efficient, relies on indirect heat conduction |

| Maintenance | Requires regular cleaning to avoid residue buildup | Simple design, easier to clean |

| Durability | Potential mechanical wear over time | More durable, fewer moving parts |

| Noise Level | May produce mechanical noise | Quiet operation |

| Ideal Use | Large batches, consistent popping | Small batches, basic popcorn makers |

Introduction to Kernel Agitation Methods in Popcorn Makers

Kernel agitation in popcorn makers is primarily achieved through stirring rods or fixed plates, each influencing the popping process differently. Stirring rods continuously move kernels to ensure even heat distribution and reduce burning, while fixed plates rely on the natural movement of kernels during popping to prevent clumping. Understanding these kernel agitation methods helps optimize popcorn texture, preventing unpopped kernels and enhancing overall flavor.

Overview of Stirring Rod Mechanism

The stirring rod mechanism in popcorn makers continuously rotates during cooking, ensuring even kernel agitation and consistent heat distribution for uniform popping. This dynamic motion prevents kernels from sticking to the heating surface and reduces the number of unpopped kernels by promoting constant movement. Compared to fixed plates, stirring rods enhance popping efficiency and produce a higher yield of fully popped popcorn.

Fixed Plate Kernel Agitation Explained

Fixed plate kernel agitation uses a stationary surface that continuously moves the kernels by creating friction and heat distribution without mechanical stirring. This method ensures even popping by preventing kernels from sticking to the surface and promotes consistent heat contact across all kernels. Fixed plates often result in less mechanical wear and quieter operation compared to stirring rods, providing efficient and uniform popcorn production.

Efficiency of Stirring Rod vs Fixed Plate

The stirring rod in a popcorn maker enhances kernel agitation by continuously moving the kernels, ensuring even heat distribution and reducing the likelihood of burning, which increases overall popping efficiency. In contrast, a fixed plate provides minimal agitation, often causing uneven heating and a higher rate of unpopped kernels. Efficiency is significantly improved with a stirring rod, as it maintains constant motion that promotes better heat transfer and maximizes kernel popping yield.

Evenness of Popcorn Popping: Which Method Wins?

The stirring rod method ensures consistent kernel agitation by continuously moving kernels around the heating element, resulting in more even heat distribution and fewer unpopped kernels. In contrast, the fixed plate relies on stationary components to agitate kernels, which can lead to uneven popping with clusters of scorched or unpopped kernels. Therefore, stirring rods generally produce a higher yield of evenly popped popcorn, enhancing overall popping efficiency and flavor quality.

Impact on Kernel Burnt Rate and Waste

The stirring rod mechanism in popcorn makers consistently agitates kernels, reducing the chance of burning by evenly distributing heat and preventing kernels from settling at the bottom. Fixed plate systems lack active stirring, often resulting in uneven heat exposure, higher kernel burnt rate, and more waste due to scorched or unpopped kernels. Optimizing kernel agitation with a stirring rod significantly decreases waste and enhances overall popping efficiency.

Cleaning and Maintenance: Stirring Rod vs Fixed Plate

Stirring rods in popcorn makers typically require more frequent cleaning due to their moving parts, which can accumulate oil and kernel residue, making maintenance slightly more labor-intensive. Fixed plates, being stationary, have fewer components that trap debris, resulting in easier and faster cleaning processes with less risk of buildup. Choosing between the two depends on balancing the desire for efficient kernel agitation with the ease of regular cleaning and maintenance.

Durability and Longevity Comparison

Stirring rods in popcorn makers offer enhanced durability due to their dynamic motion, reducing kernel burning and ensuring even heat distribution, which extends the overall lifespan of the appliance. Fixed plates, while simpler in design, are prone to uneven kernel agitation and hotspots that can cause quicker wear and tear on heating elements. Choosing a stirring rod mechanism typically results in a more robust and long-lasting popcorn maker compared to fixed plate models.

User Experience and Convenience Factors

A stirring rod in a popcorn maker ensures even kernel agitation, reducing the likelihood of burnt or unpopped kernels while offering easy cleanup and maintenance. Fixed plates provide a simpler design with fewer moving parts, enhancing durability but potentially resulting in uneven popping and more frequent user intervention. Users seeking a consistent, hassle-free popping experience often prefer stirring rods for their performance and convenience.

Which Agitation Method is Best for Your Kitchen?

The choice between a stirring rod and a fixed plate for kernel agitation in popcorn makers depends on efficiency and popcorn quality. Stirring rods actively rotate to evenly distribute heat and prevent kernels from burning, making them ideal for consistent, fluffy popcorn. Fixed plates, being stationary, offer simpler maintenance but may result in uneven cooking and more unpopped kernels, which is less suited for kitchens aiming for optimal batch results.

Stirring Rod vs Fixed Plate for Kernel Agitation Infographic

productvia.com

productvia.com