A stirring rod in a popcorn maker pet ensures even heat distribution and prevents kernels from sticking or burning by constantly moving them during popping. In contrast, a stationary plate relies on static heat and typically results in uneven popping, with more unpopped kernels and potential scorching. Choosing a stirring rod mechanism enhances overall popcorn quality by promoting uniform kernel expansion and reducing waste.

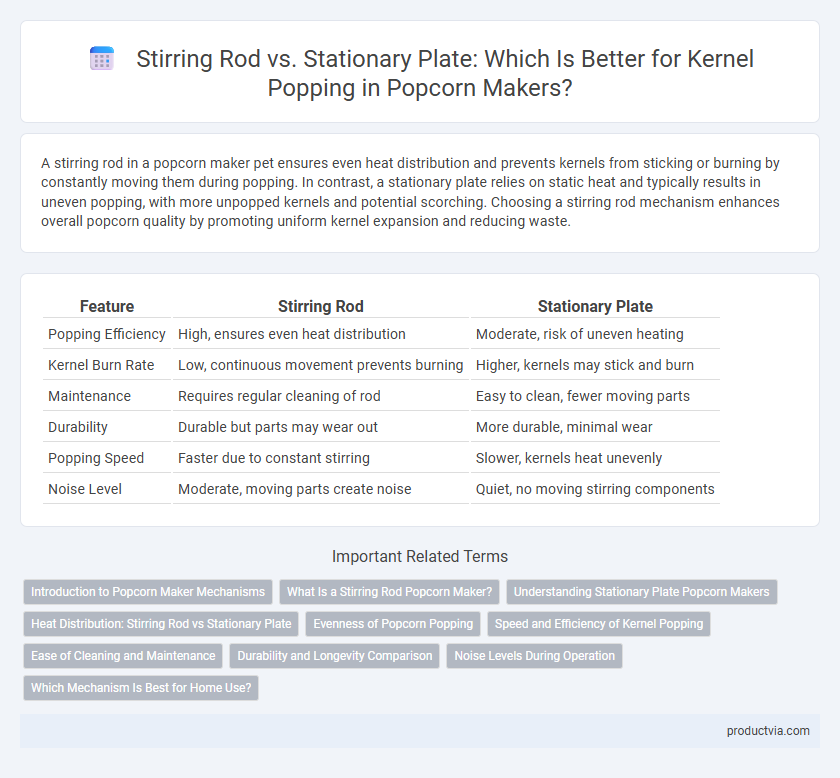

Table of Comparison

| Feature | Stirring Rod | Stationary Plate |

|---|---|---|

| Popping Efficiency | High, ensures even heat distribution | Moderate, risk of uneven heating |

| Kernel Burn Rate | Low, continuous movement prevents burning | Higher, kernels may stick and burn |

| Maintenance | Requires regular cleaning of rod | Easy to clean, fewer moving parts |

| Durability | Durable but parts may wear out | More durable, minimal wear |

| Popping Speed | Faster due to constant stirring | Slower, kernels heat unevenly |

| Noise Level | Moderate, moving parts create noise | Quiet, no moving stirring components |

Introduction to Popcorn Maker Mechanisms

Popcorn makers use different mechanisms to ensure even heat distribution and prevent kernels from burning during popping. Stirring rods continuously agitate the kernels, promoting uniform heat exposure and reducing unpopped kernels. Stationary plates rely on a fixed surface where heat transfers more slowly, which can lead to uneven popping and an increased number of unpopped or burnt kernels.

What Is a Stirring Rod Popcorn Maker?

A stirring rod popcorn maker uses a rotating arm to continuously stir kernels, promoting even heat distribution and preventing burning for consistently popped corn. In contrast, a stationary plate popcorn maker relies on a fixed base where kernels sit without movement, often resulting in uneven popping and more unpopped kernels. The stirring rod mechanism improves efficiency and enhances kernel popping performance by agitating the kernels throughout the cooking process.

Understanding Stationary Plate Popcorn Makers

Stationary plate popcorn makers rely on a fixed plate to hold kernels while heat circulates, ensuring even cooking without constant agitation. Unlike stirring rods that mechanically toss kernels, stationary plates use indirect heat transfer, reducing kernel breakage and enhancing fluffy texture. This method optimizes popping performance by maintaining kernel stability, resulting in fewer unpopped kernels and consistent popcorn quality.

Heat Distribution: Stirring Rod vs Stationary Plate

Stirring rods enhance heat distribution by continuously moving kernels, preventing hot spots and ensuring even exposure to heat, which results in more consistent popping. Stationary plates, on the other hand, rely on a fixed surface where kernels may receive uneven heat, causing some to burn while others remain unpopped. Effective heat distribution in popcorn makers is crucial for maximizing kernel yield and minimizing burnt popcorn.

Evenness of Popcorn Popping

A stirring rod in a popcorn maker continuously moves the kernels, promoting uniform heat distribution and reducing the likelihood of unpopped kernels, resulting in more consistently popped popcorn. In contrast, a stationary plate allows kernels to stay in place, which can cause uneven heating and increase the risk of burning or under-popped kernels. Using a stirring rod improves the evenness of popcorn popping by ensuring each kernel receives constant, balanced heat exposure throughout the popping process.

Speed and Efficiency of Kernel Popping

Stirring rods enhance kernel popping speed by continuously moving the kernels, preventing burning and ensuring even heat distribution for maximum efficiency. Stationary plates rely on fixed heat, which may cause uneven popping and slower overall performance. The dynamic motion of stirring rods consistently yields higher popcorn output with fewer unpopped kernels.

Ease of Cleaning and Maintenance

A stirring rod in popcorn makers prevents kernels from sticking and burning, but it requires thorough cleaning after each use due to food residue buildup on the rod and its mechanism. In contrast, a stationary plate design simplifies maintenance, as it has fewer moving parts and is easier to wipe down, reducing cleaning time. Both options need regular care, but stationary plates offer a more user-friendly experience for ease of cleaning and long-term upkeep.

Durability and Longevity Comparison

Stirring rods in popcorn makers provide consistent agitation, reducing kernel scorching and promoting even popping, which enhances the appliance's durability by preventing motor strain. Stationary plates lack moving parts, resulting in fewer mechanical failures and longer lifespan but may cause uneven cooking and increased kernel burning. Choosing between stirring rods and stationary plates involves balancing frequent mechanical maintenance against potential premature component wear due to uneven heat distribution.

Noise Levels During Operation

Stirring rods in popcorn makers create more noise due to continuous mechanical movement, producing a noticeable clicking or clattering sound as kernels are agitated. Stationary plates generate significantly less noise since they keep kernels still, relying on heat distribution without constant motion. For quieter operation, stationary plate models are preferred, especially in environments where noise reduction is important.

Which Mechanism Is Best for Home Use?

A stirring rod mechanism ensures even heat distribution by continuously agitating kernels, reducing the risk of burning and promoting consistent popping, making it ideal for home use where batch size varies. In contrast, a stationary plate relies on fixed heat application, which can cause uneven popping and increased kernel loss, but it typically requires less maintenance and has a simpler design. Home users seeking efficient, uniform popping benefit most from popcorn makers with stirring rods due to their superior kernel coverage and reduced burning incidents.

Stirring rod vs stationary plate for kernel popping Infographic

productvia.com

productvia.com