A popcorn maker pet with a nonstick surface significantly simplifies cleanup compared to bare metal models. The nonstick coating prevents popcorn and oil from adhering stubbornly, enabling quick and effortless washing. Bare metal surfaces may require more scrubbing and soaking to remove residue, making maintenance more time-consuming.

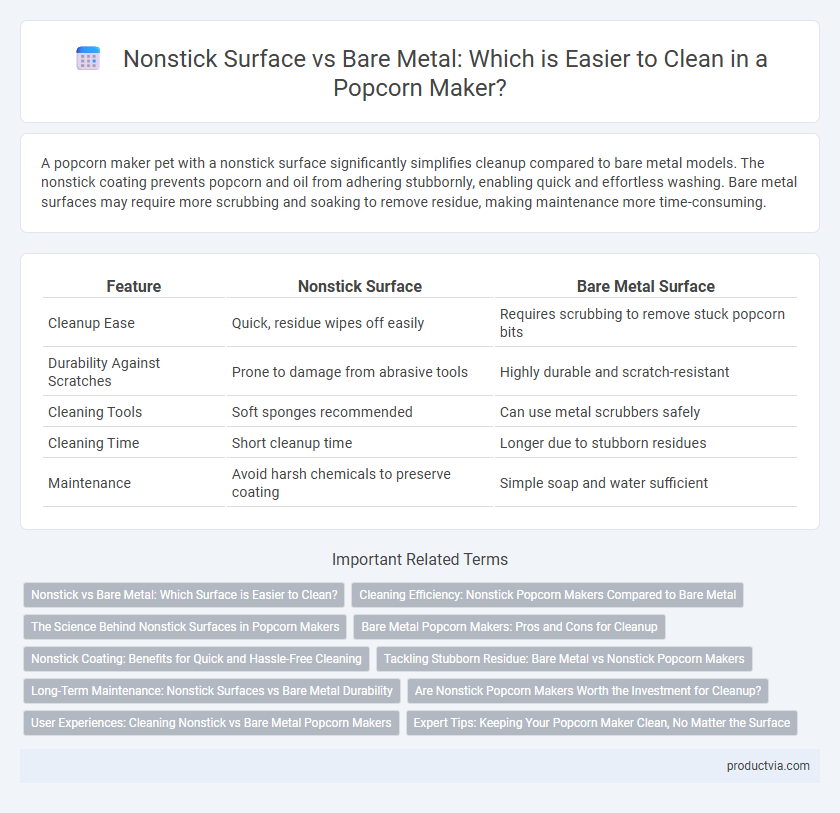

Table of Comparison

| Feature | Nonstick Surface | Bare Metal Surface |

|---|---|---|

| Cleanup Ease | Quick, residue wipes off easily | Requires scrubbing to remove stuck popcorn bits |

| Durability Against Scratches | Prone to damage from abrasive tools | Highly durable and scratch-resistant |

| Cleaning Tools | Soft sponges recommended | Can use metal scrubbers safely |

| Cleaning Time | Short cleanup time | Longer due to stubborn residues |

| Maintenance | Avoid harsh chemicals to preserve coating | Simple soap and water sufficient |

Nonstick vs Bare Metal: Which Surface is Easier to Clean?

A nonstick surface on popcorn makers allows for effortless cleanup by preventing kernels and oil from adhering, reducing residue buildup compared to bare metal. Bare metal surfaces often require more scrubbing and soaking to remove stuck popcorn and grease, increasing cleaning time and effort. Choosing a nonstick popcorn maker enhances convenience and maintains the cooking surface's longevity by minimizing abrasive cleaning.

Cleaning Efficiency: Nonstick Popcorn Makers Compared to Bare Metal

Nonstick popcorn makers offer superior cleaning efficiency compared to bare metal counterparts due to their smooth, coated surfaces that prevent popcorn and oil residue from sticking. Bare metal popcorn makers often require more vigorous scrubbing to remove stubborn burnt-on particles, increasing cleanup time and effort. The nonstick coating significantly reduces residue buildup, making maintenance quicker and preserving the maker's performance over time.

The Science Behind Nonstick Surfaces in Popcorn Makers

Nonstick surfaces in popcorn makers utilize a polymer coating, such as polytetrafluoroethylene (PTFE), that creates a low-friction barrier preventing popcorn and oil from adhering to the metal. This science-driven design significantly reduces residue buildup and facilitates effortless cleanup compared to bare metal surfaces, which rely solely on physical non-stick properties that weaken over time. The thermal conductivity of metals combined with the nonstick layer optimizes heat distribution while minimizing sticky residue, making maintenance faster and more efficient.

Bare Metal Popcorn Makers: Pros and Cons for Cleanup

Bare metal popcorn makers feature a smooth, uncoated surface that allows for easy scraping and thorough cleaning without the risk of damaging a nonstick layer. They can withstand abrasive cleaning tools and high heat, making it easier to remove burnt kernels and residue. However, bare metal surfaces may require more frequent oiling or seasoning to prevent sticking and corrosion, increasing maintenance effort compared to nonstick alternatives.

Nonstick Coating: Benefits for Quick and Hassle-Free Cleaning

Nonstick coating on popcorn makers significantly reduces residue buildup, allowing for effortless cleanup with just a simple wipe. Unlike bare metal surfaces that often require scrubbing to remove stuck kernels and oil, nonstick surfaces resist adhesion, preserving the pan's condition and enhancing durability. This feature not only saves time but also minimizes the use of harsh cleaning agents, promoting safer and more convenient maintenance.

Tackling Stubborn Residue: Bare Metal vs Nonstick Popcorn Makers

Bare metal popcorn makers excel at handling stubborn residue through vigorous scrubbing and high-heat cleaning methods without damaging the surface. Nonstick popcorn makers offer effortless cleanup as their coated surfaces resist residue adhesion, minimizing the need for intense scrubbing but may degrade over time with abrasive cleaning. Choosing between bare metal and nonstick surfaces hinges on balancing durability for tough cleanup against ease of maintenance in popcorn preparation.

Long-Term Maintenance: Nonstick Surfaces vs Bare Metal Durability

Nonstick surfaces on popcorn makers simplify cleanup by preventing food residue from adhering, reducing the need for abrasive scrubbing and extending the appliance's lifespan. Bare metal, while more prone to sticking, can endure high temperatures and withstand more rigorous cleaning methods, often lasting longer if properly maintained. Choosing between nonstick and bare metal involves balancing easy daily maintenance with long-term durability and the potential for surface degradation over time.

Are Nonstick Popcorn Makers Worth the Investment for Cleanup?

Nonstick popcorn makers significantly reduce cleanup time by preventing kernels and oil from sticking, making them ideal for frequent use. Bare metal surfaces often require more effort to scrub off residue and can degrade over time with harsh cleaning. Investing in a nonstick popcorn maker enhances convenience and maintains the appliance's condition, providing long-term value despite a higher initial cost.

User Experiences: Cleaning Nonstick vs Bare Metal Popcorn Makers

Users report that nonstick popcorn makers significantly reduce cleanup time by preventing popcorn residue and oil from adhering to the surface, making washing straightforward with minimal scrubbing. Bare metal models often require soaking and vigorous scrubbing to remove burned kernels and oil buildup, leading to longer, more labor-intensive cleanup. Consumer reviews highlight that nonstick surfaces maintain performance and ease of maintenance over extended use, enhancing the overall user experience in popcorn maker care.

Expert Tips: Keeping Your Popcorn Maker Clean, No Matter the Surface

Nonstick surfaces on popcorn makers simplify cleanup by preventing kernels and oil residues from adhering, allowing quick wiping with a soft cloth. Bare metal models require more thorough cleaning, often needing gentle scrubbing with a nylon brush and mild detergent to remove stubborn buildup. Experts recommend immediate cleaning after use and avoiding abrasive materials to maintain the integrity of both nonstick coatings and bare metal finishes.

Nonstick surface vs bare metal for cleanup Infographic

productvia.com

productvia.com