A popcorn maker pet with a nonstick chamber offers effortless cleaning by preventing kernels and oil from sticking to the surface, saving time and effort. In contrast, aluminum chambers may require more scrubbing and soaking due to their porous nature. Choosing a nonstick chamber ensures a hassle-free cleanup experience after every popcorn batch.

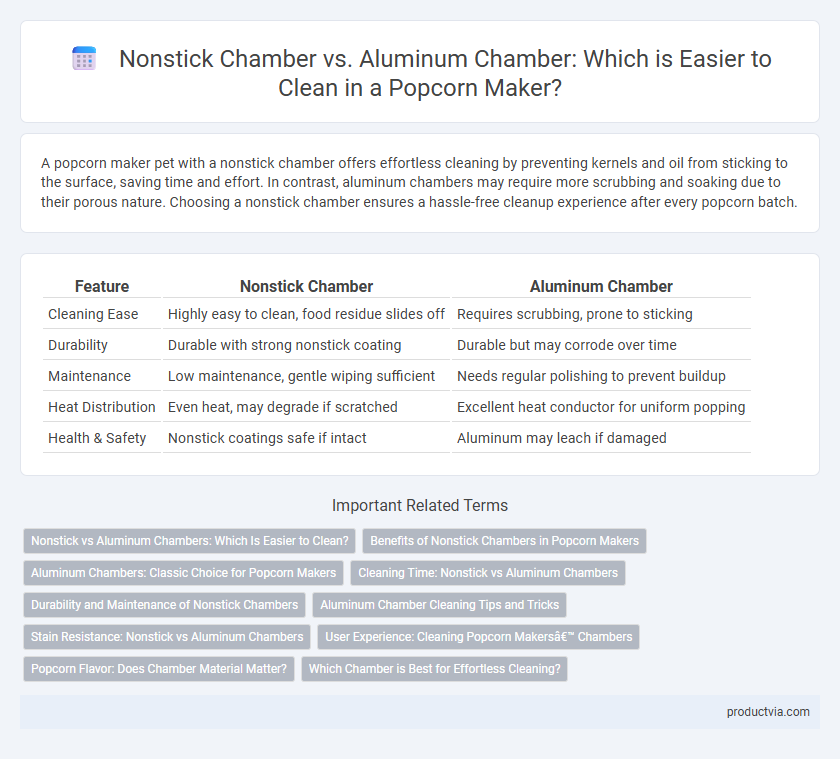

Table of Comparison

| Feature | Nonstick Chamber | Aluminum Chamber |

|---|---|---|

| Cleaning Ease | Highly easy to clean, food residue slides off | Requires scrubbing, prone to sticking |

| Durability | Durable with strong nonstick coating | Durable but may corrode over time |

| Maintenance | Low maintenance, gentle wiping sufficient | Needs regular polishing to prevent buildup |

| Heat Distribution | Even heat, may degrade if scratched | Excellent heat conductor for uniform popping |

| Health & Safety | Nonstick coatings safe if intact | Aluminum may leach if damaged |

Nonstick vs Aluminum Chambers: Which Is Easier to Clean?

Nonstick chambers offer superior ease of cleaning compared to aluminum chambers due to their smooth, coated surfaces that prevent popcorn kernels and oil from sticking. Aluminum chambers, while durable and heat conductive, often require more scrubbing as residues adhere to the porous metal surface. Choosing a popcorn maker with a nonstick chamber reduces cleaning time and effort, enhancing user convenience and maintenance.

Benefits of Nonstick Chambers in Popcorn Makers

Nonstick chambers in popcorn makers provide a smooth surface that prevents kernels and oil from sticking, significantly reducing cleaning time and effort. These chambers enhance durability by resisting scratches and corrosion compared to aluminum counterparts, ensuring consistent performance over time. Their easy-to-clean nature also promotes better hygiene by preventing residue buildup, making popcorn preparation more efficient and enjoyable.

Aluminum Chambers: Classic Choice for Popcorn Makers

Aluminum chambers in popcorn makers offer excellent heat conduction and durability, making them a classic choice for consistent popping performance. Unlike nonstick chambers, aluminum surfaces can handle higher temperatures without degrading, but they may require more effort for cleaning due to popcorn residue adherence. Choosing aluminum ensures long-lasting use and efficient heat distribution, though maintenance involves regular manual cleaning to prevent buildup.

Cleaning Time: Nonstick vs Aluminum Chambers

Nonstick popcorn maker chambers significantly reduce cleaning time due to their smooth, coated surfaces that prevent kernels and oil from sticking. Aluminum chambers often require more effort and scrubbing because food residue adheres directly to the porous metal surface. Choosing a nonstick chamber enhances convenience and maintains efficiency for quick, hassle-free popcorn machine maintenance.

Durability and Maintenance of Nonstick Chambers

Nonstick chambers in popcorn makers offer superior durability due to their resistant coating that prevents food residue from sticking, making maintenance effortless compared to aluminum chambers. The nonstick surface requires less scrubbing and reduces the risk of scratches and corrosion, significantly extending the lifespan of the cooking chamber. Regular gentle cleaning with a soft cloth maintains the integrity of the nonstick coating, ensuring long-term performance and ease of use.

Aluminum Chamber Cleaning Tips and Tricks

Aluminum chambers in popcorn makers offer excellent heat conductivity but require specific cleaning methods to maintain their nonstick properties and prevent discoloration. Use warm soapy water with a soft sponge to avoid scratching the surface, and avoid abrasive cleaners that can damage the aluminum finish. Regular seasoning with a thin layer of cooking oil can help preserve the chamber's nonstick quality and simplify future cleanings.

Stain Resistance: Nonstick vs Aluminum Chambers

Nonstick popcorn maker chambers provide superior stain resistance by preventing food particles and oils from adhering, making cleaning effortless and quick. Aluminum chambers tend to absorb oils and residues, leading to persistent stains that require more intensive scrubbing. Choosing a nonstick chamber significantly reduces maintenance time and preserves the appliance's appearance over repeated use.

User Experience: Cleaning Popcorn Makers’ Chambers

Nonstick chambers provide a smoother surface that resists stubborn popcorn residue, making cleanup faster and less labor-intensive. Aluminum chambers, while durable and excellent for heat conductivity, often require more thorough scrubbing to remove stuck-on oils and kernels. Users typically find popcorn makers with nonstick interiors enhance overall satisfaction by simplifying maintenance and preserving the chamber's pristine condition longer.

Popcorn Flavor: Does Chamber Material Matter?

Popcorn makers with nonstick chambers typically allow for easier cleaning compared to aluminum chambers, reducing oil and residue buildup that can alter popcorn flavor. Aluminum chambers conduct heat evenly but may retain odors and oils, potentially affecting the pure taste of popcorn over time. Selecting a nonstick chamber helps maintain consistent popcorn flavor by minimizing residue retention and simplifying maintenance.

Which Chamber is Best for Effortless Cleaning?

Nonstick chambers in popcorn makers offer superior ease of cleaning due to their smooth, coated surfaces that prevent popcorn residue from sticking. Aluminum chambers, while durable and excellent for heat conduction, often require more scrubbing as food particles adhere more stubbornly. For effortless cleaning and maintenance, nonstick chambers are generally the best choice.

Nonstick chamber vs aluminum chamber for easy cleaning Infographic

productvia.com

productvia.com