Direct drive stand mixers offer a more efficient power transfer by connecting the motor directly to the mixing head, resulting in increased durability and quieter operation. Belt drive stand mixers use a belt to transfer power, which can provide smoother, gentler mixing but may require more maintenance and is generally less powerful. Choosing between direct drive and belt drive depends on the desired balance of power, noise level, and long-term reliability.

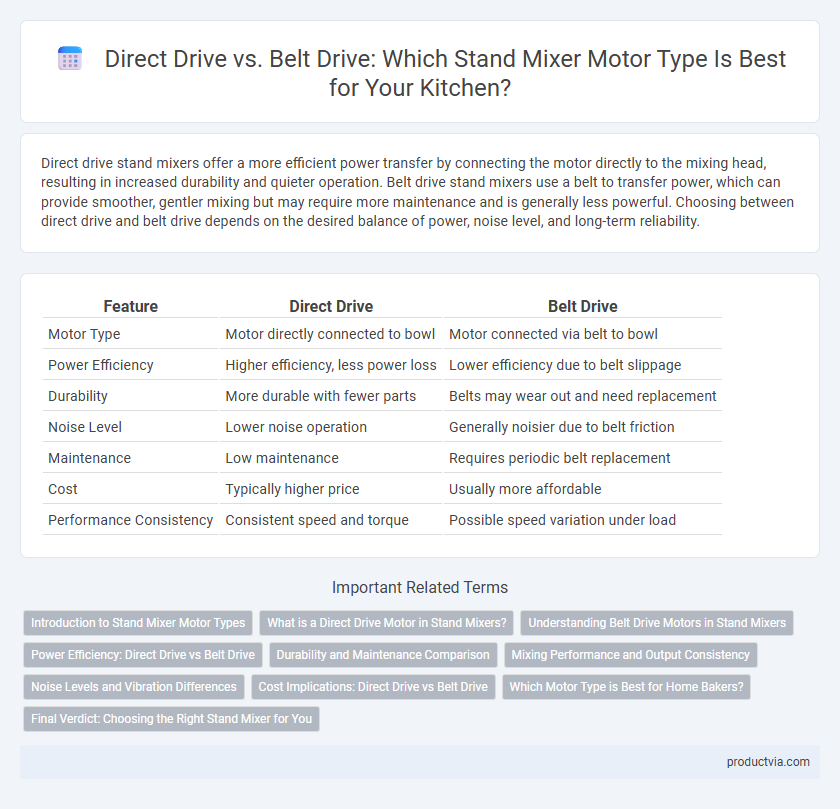

Table of Comparison

| Feature | Direct Drive | Belt Drive |

|---|---|---|

| Motor Type | Motor directly connected to bowl | Motor connected via belt to bowl |

| Power Efficiency | Higher efficiency, less power loss | Lower efficiency due to belt slippage |

| Durability | More durable with fewer parts | Belts may wear out and need replacement |

| Noise Level | Lower noise operation | Generally noisier due to belt friction |

| Maintenance | Low maintenance | Requires periodic belt replacement |

| Cost | Typically higher price | Usually more affordable |

| Performance Consistency | Consistent speed and torque | Possible speed variation under load |

Introduction to Stand Mixer Motor Types

Direct drive stand mixers feature a motor connected directly to the mixing mechanism, delivering higher torque and greater durability for heavy-duty mixing tasks. Belt drive stand mixers utilize a belt system to transfer power from the motor to the mixing bowl, often resulting in quieter operation and smoother speed adjustments. Choosing between these motor types depends on factors like mixing power requirements, noise preferences, and overall appliance longevity.

What is a Direct Drive Motor in Stand Mixers?

A direct drive motor in stand mixers connects the motor directly to the mixing attachment, providing enhanced power transfer and durability. This design reduces energy loss and motor strain, resulting in consistent mixing performance and longer lifespan compared to belt drive systems. Stand mixers with direct drive motors typically offer greater torque, making them ideal for heavy-duty baking and mixing tasks.

Understanding Belt Drive Motors in Stand Mixers

Belt drive motors in stand mixers use a belt and pulley system to transfer power from the motor to the mixing attachment, providing smoother and quieter operation. This design helps absorb motor vibrations, reducing noise levels and preventing overheating during extended mixing tasks. Although belt-driven mixers may have slightly less torque than direct drive models, they often offer enhanced durability and longer motor lifespan due to reduced mechanical stress.

Power Efficiency: Direct Drive vs Belt Drive

Direct drive stand mixers transfer motor power directly to the mixing mechanism, resulting in higher power efficiency and less energy loss. Belt drive mixers experience energy loss due to belt friction and slippage, which reduces overall efficiency and requires more maintenance. For users prioritizing consistent torque and energy savings, direct drive systems provide a more efficient and durable solution.

Durability and Maintenance Comparison

Direct drive stand mixers offer superior durability due to the motor being directly connected to the mixing attachment, reducing wear and tear on components. Belt drive mixers require regular belt replacements and adjustments, increasing maintenance efforts over time. For users prioritizing long-term reliability, direct drive motors provide a more robust and low-maintenance solution.

Mixing Performance and Output Consistency

Direct drive stand mixers deliver superior mixing performance and output consistency by transmitting power directly from the motor to the mixing mechanism, reducing energy loss and mechanical wear. Belt drive mixers tend to have more vibration and less precision, which can result in uneven mixing and variable product texture. For tasks requiring consistent dough kneading and batter mixing, direct drive motors provide enhanced reliability and smoother operation.

Noise Levels and Vibration Differences

Direct drive stand mixers typically produce less noise and vibration because the motor is directly connected to the mixing bowl, resulting in more efficient power transfer and reduced mechanical friction. Belt drive mixers often generate higher noise levels and more vibration due to the additional belt component which can slip or loosen over time, causing inconsistent motor performance. Choosing a direct drive stand mixer enhances durability and provides a quieter, smoother mixing experience.

Cost Implications: Direct Drive vs Belt Drive

Direct drive stand mixers generally feature higher upfront costs due to their integrated motor design and enhanced durability, making them a long-term investment for frequent bakers. Belt drive mixers offer a lower initial price and simpler maintenance but may incur additional expenses over time from belt replacements and potential motor strain. Evaluating these cost implications helps consumers balance budget constraints with desired mixer performance and longevity.

Which Motor Type is Best for Home Bakers?

Direct drive motors in stand mixers offer superior power transfer and durability, making them ideal for heavy doughs and frequent use, which benefits home bakers seeking consistent performance. Belt drive mixers tend to be quieter and less expensive but may lack the torque needed for dense mixtures or prolonged baking tasks. For home bakers prioritizing reliability and efficiency, direct drive motors generally provide the best balance of power and longevity.

Final Verdict: Choosing the Right Stand Mixer for You

Direct drive stand mixers offer superior power and durability with the motor directly connected to the mixing mechanism, making them ideal for heavy-duty baking tasks. Belt drive mixers provide quieter operation and more affordable options but may sacrifice some torque and long-term reliability. Selecting the right stand mixer depends on your baking frequency and intensity, where direct drive suits professional or frequent bakers, and belt drive fits casual users prioritizing quieter, budget-friendly appliances.

Direct drive vs Belt drive for stand mixer motor type Infographic

productvia.com

productvia.com