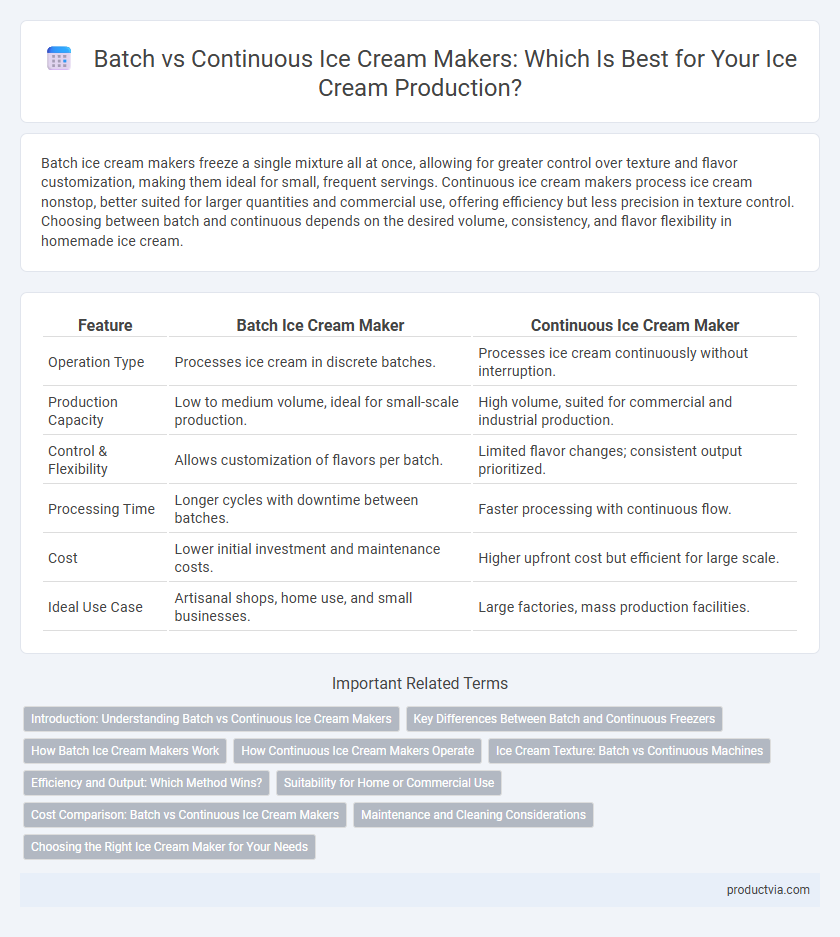

Batch ice cream makers freeze a single mixture all at once, allowing for greater control over texture and flavor customization, making them ideal for small, frequent servings. Continuous ice cream makers process ice cream nonstop, better suited for larger quantities and commercial use, offering efficiency but less precision in texture control. Choosing between batch and continuous depends on the desired volume, consistency, and flavor flexibility in homemade ice cream.

Table of Comparison

| Feature | Batch Ice Cream Maker | Continuous Ice Cream Maker |

|---|---|---|

| Operation Type | Processes ice cream in discrete batches. | Processes ice cream continuously without interruption. |

| Production Capacity | Low to medium volume, ideal for small-scale production. | High volume, suited for commercial and industrial production. |

| Control & Flexibility | Allows customization of flavors per batch. | Limited flavor changes; consistent output prioritized. |

| Processing Time | Longer cycles with downtime between batches. | Faster processing with continuous flow. |

| Cost | Lower initial investment and maintenance costs. | Higher upfront cost but efficient for large scale. |

| Ideal Use Case | Artisanal shops, home use, and small businesses. | Large factories, mass production facilities. |

Introduction: Understanding Batch vs Continuous Ice Cream Makers

Batch ice cream makers produce a set amount of ice cream per cycle, ideal for home use and small quantities due to their simplicity and ease of cleaning. Continuous ice cream makers operate non-stop, suitable for commercial use where large volumes and consistent texture are required, utilizing mechanisms that churn and freeze simultaneously. Choosing between batch and continuous models depends on production scale, desired texture, and operational efficiency.

Key Differences Between Batch and Continuous Freezers

Batch freezers produce ice cream in small, discrete portions, allowing precise control over texture and flavor customization; continuous freezers, in contrast, operate nonstop, ideal for large-scale production with consistent quality. Batch freezers mix and freeze ingredients simultaneously, resulting in varied textures, while continuous freezers use a constant freezing process that ensures uniformity and higher production rates. The primary differences lie in production volume, process control, and output consistency, with batch freezers suited for artisan ice cream and continuous freezers for commercial manufacturing.

How Batch Ice Cream Makers Work

Batch ice cream makers operate by mixing and freezing a single portion of ingredients at a time, ensuring controlled texture and flavor development. These machines use a rotating paddle to churn the mixture while simultaneously cooling it, incorporating air to create a smooth and creamy consistency. The process typically takes 20 to 40 minutes, allowing for customization and small-batch production ideal for home use.

How Continuous Ice Cream Makers Operate

Continuous ice cream makers operate by constantly mixing and freezing the ice cream base as it flows through the machine, allowing for uninterrupted production and consistent texture. This process uses a refrigeration system combined with a high-speed dasher to incorporate air evenly, creating smooth, creamy ice cream in larger volumes. Continuous machines are ideal for commercial use where efficiency and capacity are critical factors.

Ice Cream Texture: Batch vs Continuous Machines

Batch ice cream makers produce richer, creamier textures by freezing and churning small quantities slowly, allowing air incorporation and ice crystal control. Continuous ice cream machines handle large volumes rapidly, delivering smoother textures with consistent quality by maintaining constant freezing and mixing. The choice impacts texture quality, with batch machines favored for artisanal, dense ice cream and continuous machines suited for uniform, mass-produced products.

Efficiency and Output: Which Method Wins?

Batch ice cream makers excel in small-scale, artisanal production, offering flexibility and control over ingredients but limited output per cycle. Continuous ice cream makers deliver high efficiency by producing large volumes consistently without interruption, making them ideal for commercial operations. For maximizing output and operational efficiency, continuous methods outperform batch systems in industrial settings.

Suitability for Home or Commercial Use

Batch ice cream makers are ideal for home use due to their smaller capacity and ease of operation, producing limited quantities with a hands-on approach. Continuous ice cream makers suit commercial use by enabling large-scale production with consistent output and minimal manual intervention. The choice depends on volume requirements and operational complexity, with batch machines favored for artisan or occasional use and continuous machines optimized for high-demand environments.

Cost Comparison: Batch vs Continuous Ice Cream Makers

Batch ice cream makers generally come with a lower upfront cost, making them ideal for small-scale or home use, while continuous ice cream makers require a higher initial investment due to advanced machinery suited for large-scale production. Operational expenses for batch machines tend to be lower but increase with labor intensity and longer production times, whereas continuous machines offer efficiency that reduces per-unit costs despite higher maintenance and energy consumption. Evaluating total cost of ownership involves weighing initial purchase price, production capacity, labor costs, and maintenance expenses to determine the most cost-effective solution for different production needs.

Maintenance and Cleaning Considerations

Batch ice cream makers typically require more thorough cleaning after each use since the entire mixture is processed at once, increasing the likelihood of residue buildup. Continuous ice cream makers feature automated cleaning cycles and fewer disassemblies, reducing downtime and maintenance frequency. Proper maintenance of batch machines includes dismantling paddles and freezing bowls, while continuous machines demand regular filter and conveyor inspections to prevent mechanical wear.

Choosing the Right Ice Cream Maker for Your Needs

Batch ice cream makers produce small to medium quantities per cycle, ideal for homemade treats with varied flavors and customizable ingredients. Continuous ice cream makers efficiently produce large volumes with consistent texture, suitable for commercial use or frequent large-batch production. Selecting the right ice cream maker depends on your desired production scale, flavor experimentation, and frequency of use.

Batch vs Continuous for ice cream maker Infographic

productvia.com

productvia.com