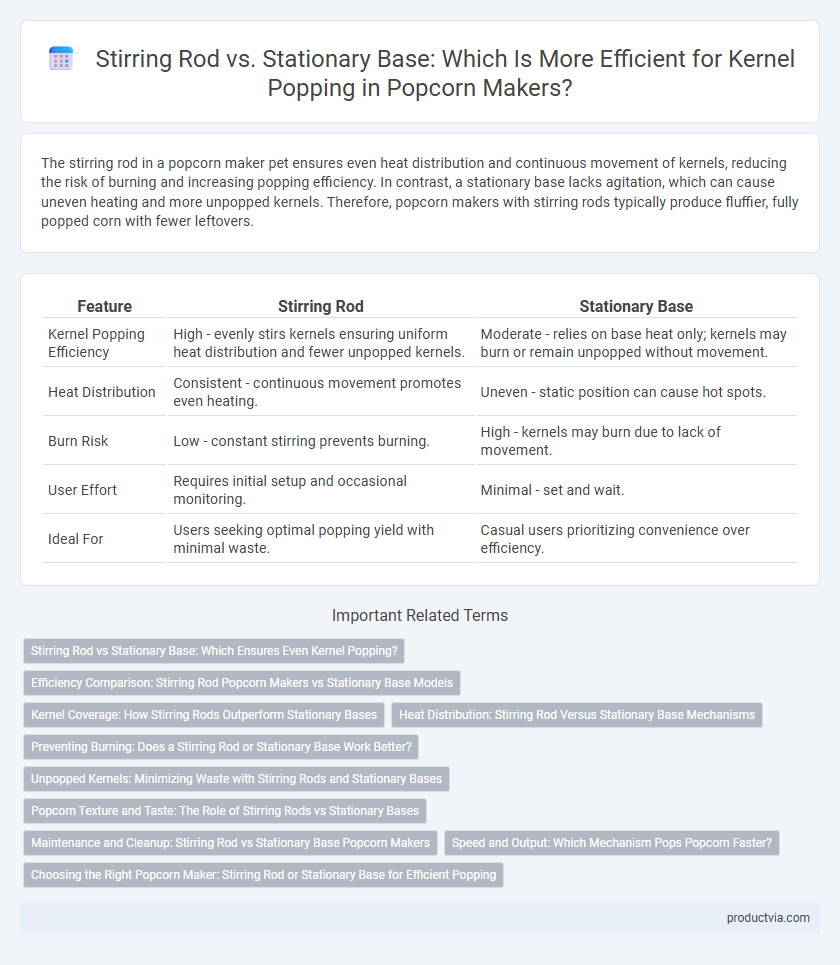

The stirring rod in a popcorn maker pet ensures even heat distribution and continuous movement of kernels, reducing the risk of burning and increasing popping efficiency. In contrast, a stationary base lacks agitation, which can cause uneven heating and more unpopped kernels. Therefore, popcorn makers with stirring rods typically produce fluffier, fully popped corn with fewer leftovers.

Table of Comparison

| Feature | Stirring Rod | Stationary Base |

|---|---|---|

| Kernel Popping Efficiency | High - evenly stirs kernels ensuring uniform heat distribution and fewer unpopped kernels. | Moderate - relies on base heat only; kernels may burn or remain unpopped without movement. |

| Heat Distribution | Consistent - continuous movement promotes even heating. | Uneven - static position can cause hot spots. |

| Burn Risk | Low - constant stirring prevents burning. | High - kernels may burn due to lack of movement. |

| User Effort | Requires initial setup and occasional monitoring. | Minimal - set and wait. |

| Ideal For | Users seeking optimal popping yield with minimal waste. | Casual users prioritizing convenience over efficiency. |

Stirring Rod vs Stationary Base: Which Ensures Even Kernel Popping?

Stirring rods in popcorn makers promote even kernel popping by continuously agitating the kernels, preventing them from sticking to the base and ensuring uniform heat distribution. In contrast, stationary bases often result in uneven popping with more unpopped or burnt kernels due to localized heat spots and lack of movement. Therefore, models equipped with stirring rods typically achieve higher popping efficiency and better overall popcorn quality.

Efficiency Comparison: Stirring Rod Popcorn Makers vs Stationary Base Models

Stirring rod popcorn makers significantly enhance kernel popping efficiency by continuously agitating kernels, ensuring even heat distribution and reducing the number of unpopped kernels. Stationary base models often result in uneven heating and clustering, leading to higher rates of burnt or unpopped popcorn. The mechanical action of stirring rods maximizes yield and produces consistently fluffy popcorn compared to the passive heating method of stationary bases.

Kernel Coverage: How Stirring Rods Outperform Stationary Bases

Stirring rods enhance kernel popping efficiency by continuously agitating kernels, ensuring even heat distribution and preventing clumping. This constant movement guarantees uniform kernel coverage, reducing the number of unpopped kernels compared to stationary bases. By maintaining optimal contact with heat, stirring rods significantly improve overall popping performance and yield.

Heat Distribution: Stirring Rod Versus Stationary Base Mechanisms

The stirring rod in popcorn makers ensures even heat distribution by continuously agitating kernels, preventing hot spots and promoting uniform popping. In contrast, a stationary base relies solely on conduction, leading to uneven heat transfer and increased risk of burning some kernels while leaving others unpopped. Efficient kernel popping is significantly enhanced by the dynamic motion of stirring rods optimizing heat exposure across all kernels.

Preventing Burning: Does a Stirring Rod or Stationary Base Work Better?

A stirring rod significantly enhances kernel popping efficiency by continuously agitating the kernels, ensuring even heat distribution and preventing burning. In contrast, a stationary base often results in uneven heat exposure, causing some kernels to scorch while others remain unpopped. Using a stirring rod reduces the risk of burnt popcorn, leading to a higher yield of perfectly popped kernels.

Unpopped Kernels: Minimizing Waste with Stirring Rods and Stationary Bases

Stirring rods significantly reduce the number of unpopped kernels by continuously agitating the kernels, ensuring even heat distribution and preventing burning. Stationary bases, while simpler, often result in uneven heating and a higher percentage of waste due to unpopped kernels stuck at the bottom. Utilizing a popcorn maker with a stirring rod enhances kernel popping efficiency and minimizes waste, making it ideal for optimal snack preparation.

Popcorn Texture and Taste: The Role of Stirring Rods vs Stationary Bases

Stirring rods enhance popcorn texture and taste by evenly distributing heat and preventing kernels from burning, resulting in consistently fluffy and well-popped popcorn. In contrast, stationary bases often cause uneven heating, leading to a higher number of unpopped kernels and a burnt or uneven flavor profile. The mechanical motion of stirring rods ensures optimal kernel exposure to heat, maximizing popping efficiency and improving overall popcorn quality.

Maintenance and Cleanup: Stirring Rod vs Stationary Base Popcorn Makers

Stirring rod popcorn makers require regular cleaning to remove kernel residues and prevent buildup, ensuring smooth rotation and consistent popping efficiency. Stationary base models often have fewer moving parts, simplifying maintenance and reducing the risk of mechanical issues but may experience uneven kernel heating. Proper cleaning of the stirring rod components extends the appliance's lifespan, while stationary bases benefit from straightforward wipe-downs, making each design distinct in maintenance effort and overall operational efficiency.

Speed and Output: Which Mechanism Pops Popcorn Faster?

A stirring rod mechanism continuously agitates kernels, promoting even heat distribution and reducing unpopped kernels, which increases popping speed and overall output. In contrast, a stationary base relies solely on heat transfer without movement, often resulting in slower popping and uneven kernel heating. Therefore, popcorn makers with stirring rods typically achieve faster popping times and higher yield efficiency compared to those with stationary bases.

Choosing the Right Popcorn Maker: Stirring Rod or Stationary Base for Efficient Popping

A popcorn maker with a stirring rod enhances kernel popping efficiency by continuously agitating the kernels, preventing burning and ensuring even heat distribution. In contrast, a stationary base relies on static heat application, which may lead to uneven popping and more unpopped kernels. Selecting a popcorn maker featuring a stirring rod optimizes popping performance and yields a higher volume of fluffy popcorn.

Stirring rod vs stationary base for kernel popping efficiency Infographic

productvia.com

productvia.com